A candy thermometer provides precise temperature readings by direct contact with the sugar mixture, ensuring accuracy critical for achieving specific candy stages. Infrared laser thermometers measure surface temperature without contact but can give less reliable results due to steam and uneven heating during candy making. For consistent and successful candy crafting, a candy thermometer remains the preferred tool over infrared models.

Table of Comparison

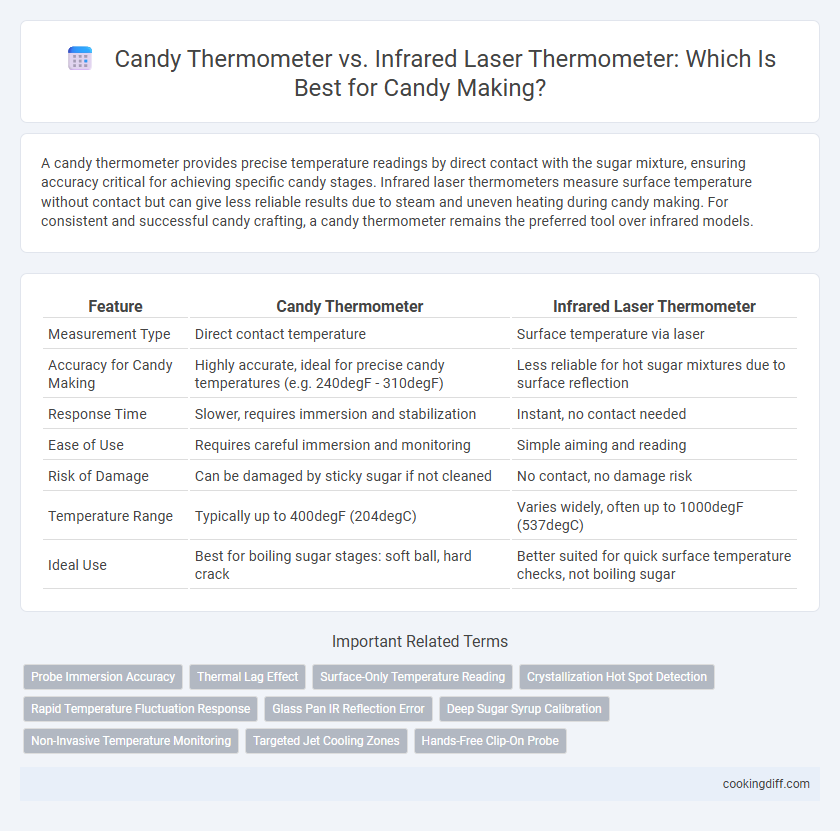

| Feature | Candy Thermometer | Infrared Laser Thermometer |

|---|---|---|

| Measurement Type | Direct contact temperature | Surface temperature via laser |

| Accuracy for Candy Making | Highly accurate, ideal for precise candy temperatures (e.g. 240degF - 310degF) | Less reliable for hot sugar mixtures due to surface reflection |

| Response Time | Slower, requires immersion and stabilization | Instant, no contact needed |

| Ease of Use | Requires careful immersion and monitoring | Simple aiming and reading |

| Risk of Damage | Can be damaged by sticky sugar if not cleaned | No contact, no damage risk |

| Temperature Range | Typically up to 400degF (204degC) | Varies widely, often up to 1000degF (537degC) |

| Ideal Use | Best for boiling sugar stages: soft ball, hard crack | Better suited for quick surface temperature checks, not boiling sugar |

Introduction to Thermometers in Candy Making

Thermometers are essential tools in candy making, ensuring precise temperature control for perfect texture and consistency. Candy thermometers measure the sugar syrup's temperature directly, providing accurate readings essential for specific stages like soft ball and hard crack.

Infrared laser thermometers offer a quick, non-contact way to gauge surface temperatures without immersion. However, they may not accurately reflect the temperature inside the syrup, making candy thermometers generally preferred for reliable candy making results.

What Is a Candy Thermometer?

A candy thermometer is a specialized kitchen tool designed to measure the precise temperature of sugar solutions during candy making, ensuring perfect texture and consistency. Unlike infrared laser thermometers, it must be immersed directly in the hot mixture to provide accurate readings of boiling sugar stages such as soft ball, hard crack, and caramel. This direct contact allows candy thermometers to monitor gradual temperature changes critical for achieving desired candy results.

Understanding Infrared Laser Thermometers

Infrared laser thermometers provide a non-contact method for measuring the surface temperature of candy mixtures quickly and safely. These devices use laser-guided sensors to detect thermal radiation, allowing precise temperature readings without immersion in the hot candy.

- Non-contact measurement - Infrared laser thermometers measure temperature from a distance, avoiding contamination and heat exposure.

- Surface temperature accuracy - They accurately gauge the surface heat of candy, crucial for consistent texture and quality.

- Instant readings - These thermometers provide rapid temperature feedback, enabling real-time adjustments during candy making.

Despite their advantages, infrared laser thermometers may not reflect the internal temperature, which is critical for some candy recipes.

Accuracy: Candy Thermometer vs Infrared Laser Thermometer

Candy thermometers provide direct contact measurement, ensuring high accuracy crucial for precise sugar temperature control during candy making. Infrared laser thermometers measure surface temperatures without contact but may yield less reliable readings due to reflective or uneven candy surfaces.

The candy thermometer's immersion technique captures the true temperature of the boiling sugar mixture, minimizing errors common in non-contact methods. Infrared laser thermometers can be influenced by ambient temperature and surface texture, leading to inconsistent results. For exact candy making stages, candy thermometers remain the preferred choice due to their proven accuracy and reliability.

Ease of Use and Practicality

Candy thermometers provide direct temperature readings by being immersed in the boiling sugar mixture, which ensures accuracy for precise candy making. Infrared laser thermometers offer a quick, non-contact method, but may struggle with accuracy on reflective or uneven surfaces typical in candy pots.

- Candy Thermometer Ease of Use - Requires placement in the hot liquid, which can be challenging but offers continuous temperature monitoring.

- Infrared Thermometer Practicality - Allows fast temperature checks without touching the mixture, ideal for quick scans but less reliable for precise sugar cookery.

- Cleaning and Maintenance - Candy thermometers need thorough cleaning after use, while infrared thermometers stay clean and are low maintenance.

Speed of Temperature Reading

| Candy Thermometer | Measures temperature by direct contact with the candy mixture, providing accurate readings essential for precise sugar stages. |

| Infrared Laser Thermometer | Offers fast, non-contact temperature readings within seconds but may deliver less consistent data due to surface-only measurement. |

| Speed of Temperature Reading | Infrared thermometers deliver quicker results, ideal for rapid checks, while candy thermometers require more time but ensure greater accuracy for candy making. |

Cleaning and Maintenance Differences

Candy thermometers require thorough cleaning after each use to remove sticky sugar residues, typically needing warm soapy water and careful handling of the probe. Infrared laser thermometers demand minimal maintenance since they do not contact the candy directly, only requiring occasional lens cleaning with a soft cloth. This difference in cleaning and maintenance makes infrared thermometers more convenient but less accurate for direct temperature measurements during candy making.

Versatility for Other Cooking Tasks

Which thermometer offers greater versatility for various cooking tasks beyond candy making? Candy thermometers, designed to monitor precise temperature ranges, excel in tasks like frying and deep-frying due to their clip-on feature and continuous reading capability. Infrared laser thermometers provide quick surface temperature measurements, making them ideal for grilling and checking oven heat but less effective for monitoring liquid temperatures continuously.

Cost and Availability Comparison

Candy thermometers are generally more affordable, with prices ranging from $10 to $30, making them accessible for home candy makers. Infrared laser thermometers tend to be more expensive, often costing between $40 and $100 due to advanced technology and versatility.

Standard candy thermometers are widely available in kitchen supply stores and online, ensuring easy replacement and purchase. Infrared laser thermometers, while available in specialty stores and online, may have limited stock specifically calibrated for candy making.

Related Important Terms

Probe Immersion Accuracy

Candy thermometers provide superior probe immersion accuracy by directly measuring the temperature within the boiling sugar mixture, ensuring precise stage identification like soft ball or hard crack. Infrared laser thermometers, while convenient for quick surface readings, lack immersion capability and often yield inconsistent internal temperatures critical for candy making precision.

Thermal Lag Effect

Candy thermometers provide direct contact measurement, minimizing thermal lag for accurate temperature readings critical in candy making. Infrared laser thermometers suffer from thermal lag due to surface temperature variance and emissivity issues, potentially leading to inaccurate candy stage detection.

Surface-Only Temperature Reading

Candy thermometers measure the internal temperature of sugar solutions, providing precise readings crucial for achieving desired candy textures. Infrared laser thermometers only capture surface temperature, which can lead to inaccurate measurements due to the uneven heat distribution in candy mixtures.

Crystallization Hot Spot Detection

Candy thermometers provide direct contact with the sugar solution, ensuring precise temperature readings critical for monitoring crystallization and preventing hot spots during candy making. Infrared laser thermometers detect surface temperature from a distance but may miss localized crystallization hot spots, increasing the risk of uneven texture in the final product.

Rapid Temperature Fluctuation Response

Candy thermometers provide precise and continuous monitoring by being immersed directly in the sugar mixture, ensuring accurate readings during rapid temperature fluctuations crucial in candy making; infrared laser thermometers, while faster and non-contact, may struggle with surface-only measurements and slower response to sudden internal temperature changes in boiling sugar. Direct immersion sensors in candy thermometers reduce lag time and improve control over critical stages like soft ball and hard crack, which infrared devices might miss due to their reliance on external surface temperature detection.

Glass Pan IR Reflection Error

Candy thermometers provide direct contact temperature readings essential for precise candy making, while infrared laser thermometers can produce inaccurate results due to IR reflection errors on glass pans. Glass surfaces reflect infrared rays, causing false temperature readings that compromise the candy's consistency and quality.

Deep Sugar Syrup Calibration

Candy thermometers provide precise temperature readings essential for deep sugar syrup calibration, ensuring accurate control during the critical stages of candy making. Infrared laser thermometers, while quick and non-contact, often struggle with reflective sugar surfaces and fail to measure internal syrup temperatures accurately, making them less reliable for deep sugar syrup calibration.

Non-Invasive Temperature Monitoring

A candy thermometer provides precise contact temperature readings essential for monitoring sugar stages during candy making, while an infrared laser thermometer offers non-invasive temperature measurement by detecting surface heat without touching the mixture. Non-invasive infrared thermometers prevent contamination and reduce the risk of crystallization but may require calibration for accurate readings on reflective or uneven surfaces.

Targeted Jet Cooling Zones

Candy thermometers provide precise temperature readings directly from the cooking liquid, ensuring accurate monitoring of sugar stages essential for candy consistency. Infrared laser thermometers target jet cooling zones on candy surfaces for instant, non-contact temperature measurements that help prevent overheating and burning during the cooling phase.

Candy Thermometer vs Infrared Laser Thermometer for candy making. Infographic

cookingdiff.com

cookingdiff.com