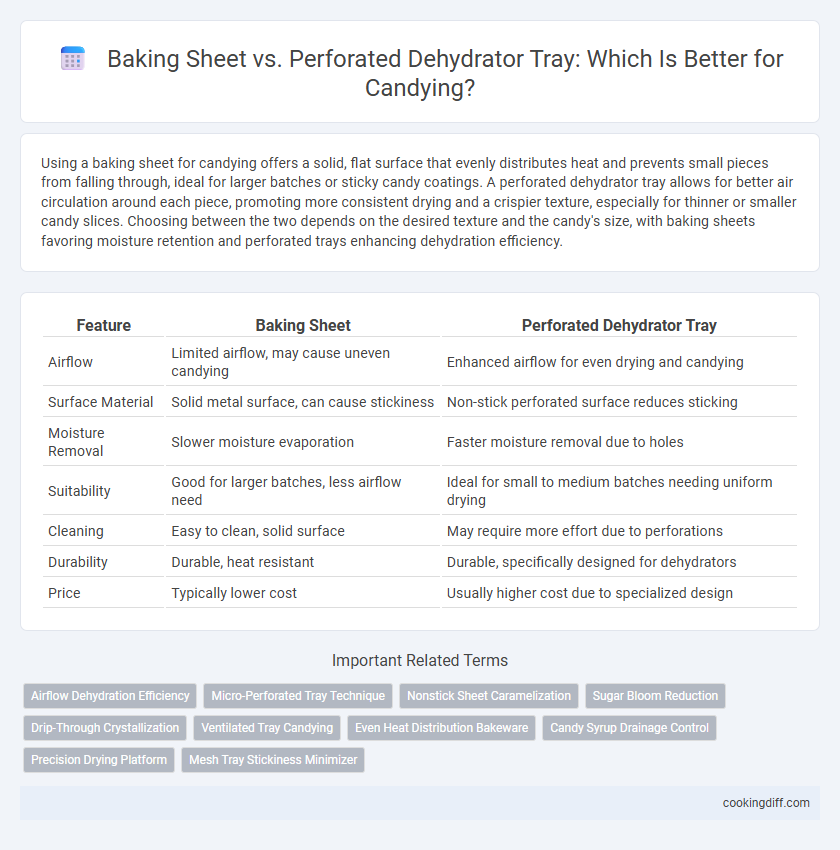

Using a baking sheet for candying offers a solid, flat surface that evenly distributes heat and prevents small pieces from falling through, ideal for larger batches or sticky candy coatings. A perforated dehydrator tray allows for better air circulation around each piece, promoting more consistent drying and a crispier texture, especially for thinner or smaller candy slices. Choosing between the two depends on the desired texture and the candy's size, with baking sheets favoring moisture retention and perforated trays enhancing dehydration efficiency.

Table of Comparison

| Feature | Baking Sheet | Perforated Dehydrator Tray |

|---|---|---|

| Airflow | Limited airflow, may cause uneven candying | Enhanced airflow for even drying and candying |

| Surface Material | Solid metal surface, can cause stickiness | Non-stick perforated surface reduces sticking |

| Moisture Removal | Slower moisture evaporation | Faster moisture removal due to holes |

| Suitability | Good for larger batches, less airflow need | Ideal for small to medium batches needing uniform drying |

| Cleaning | Easy to clean, solid surface | May require more effort due to perforations |

| Durability | Durable, heat resistant | Durable, specifically designed for dehydrators |

| Price | Typically lower cost | Usually higher cost due to specialized design |

Introduction to Candying: Essential Tools

Which tool is more effective for candying, a baking sheet or a perforated dehydrator tray? Baking sheets provide a solid surface ideal for even heating and easy cleanup during the candying process. Perforated dehydrator trays allow for better air circulation, promoting faster dehydration and consistent texture in candied fruits or vegetables.

Baking Sheet vs Perforated Dehydrator Tray: Key Differences

The key difference between a baking sheet and a perforated dehydrator tray for candying lies in airflow and moisture control, which affect drying efficiency and texture. Baking sheets generally have a solid surface, while perforated trays allow better air circulation around the candy.

- Airflow Efficiency - Perforated dehydrator trays promote even drying by allowing air to circulate beneath and around the candy, reducing drying time.

- Moisture Retention - Baking sheets tend to trap moisture underneath candies, potentially causing uneven drying or stickiness.

- Material and Heat Distribution - Baking sheets are typically made of metal with solid surfaces offering even heat distribution, whereas perforated trays prioritize airflow over conductive heat transfer.

Choosing between these depends on the desired texture and drying speed for the candy-making process.

Heat Circulation and Even Drying

Baking sheets provide a solid surface that can trap moisture, often leading to uneven drying during candying. Their design limits heat circulation, which can result in inconsistent texture and prolonged drying times.

Perforated dehydrator trays enhance heat circulation by allowing air to flow freely through the holes, promoting even drying. This design significantly reduces drying time and contributes to a uniformly candied product.

Surface Area and Candy Uniformity

Perforated dehydrator trays offer increased surface area exposure compared to solid baking sheets, enhancing airflow and promoting even candy drying. This results in improved candy uniformity and reduced risk of uneven texture or moisture retention during the candying process.

- Surface Area Advantage - Perforated trays provide better airflow due to holes, increasing drying efficiency.

- Candy Uniformity - Enhanced air circulation leads to consistent texture and moisture content across all pieces.

- Heat Distribution - Baking sheets may cause uneven heat distribution, while perforated trays ensure more uniform heat exposure.

Drip Management and Sugary Mess Control

Baking sheets often collect syrup drips during candying, leading to sticky messes that require thorough cleaning. Their solid surface traps excess sugar, which can caramelize and create challenging residue.

Perforated dehydrator trays enhance drip management by allowing excess syrup to fall through holes, reducing sugary buildup. This design minimizes mess and promotes even drying, improving the candying process efficiency.

Material Types and Durability

Baking sheets are commonly made from aluminum or stainless steel, offering excellent heat conduction and resistance to warping during candying. Perforated dehydrator trays are often constructed from food-grade plastic or stainless steel, designed to allow airflow and maintain durability under prolonged exposure to heat and moisture.

- Aluminum Baking Sheets - Lightweight and conductive, but prone to scratching and may warp under high heat.

- Stainless Steel Trays - Durable and corrosion-resistant, providing long-term use for candying processes.

- Food-Grade Plastic Dehydrator Trays - Heat-resistant and flexible, ideal for airflow but less durable compared to metal alternatives.

Ease of Cleaning and Maintenance

| Baking Sheet | Non-stick surfaces allow easy residue removal, reducing cleaning time; dishwasher-safe options simplify maintenance. |

| Perforated Dehydrator Tray | Small holes can trap sticky syrup, making cleaning more labor-intensive; requires thorough scrubbing to prevent buildup and ensure hygiene. |

Versatility in the Kitchen

Baking sheets offer versatility for candying by accommodating a variety of recipes, including caramel and candied nuts, with even heat distribution and easy cleanup. Perforated dehydrator trays excel in promoting air circulation, making them ideal for drying candied fruits evenly without sticking. Both tools enhance kitchen efficiency, but baking sheets suit broader baking needs while perforated trays specialize in controlled dehydration processes.

Performance with Different Fruits and Ingredients

A baking sheet provides uniform heat distribution ideal for candying thick fruits like apples and pears, while a perforated dehydrator tray allows better airflow suited for thinner fruits such as berries and citrus peels. The perforated tray's ventilation accelerates moisture removal, enhancing texture and preventing sogginess during candying.

The solid surface of a baking sheet holds syrups well, making it effective for sticky ingredients like caramel and nuts. Perforated trays work best for even drying of delicate cuts, preserving flavor and color without burning. Selecting the right tray depends on the fruit's moisture content and the desired candying outcome.

Related Important Terms

Airflow Dehydration Efficiency

Perforated dehydrator trays offer superior airflow and consistent dehydration efficiency compared to baking sheets, enhancing candying by promoting even moisture removal and faster drying times. Baking sheets tend to limit air circulation, which can result in uneven candy texture and extended dehydration periods.

Micro-Perforated Tray Technique

The micro-perforated tray technique enhances candying by allowing superior air circulation and moisture evaporation compared to traditional baking sheets, resulting in evenly dehydrated and crisp confections. This optimized airflow prevents sogginess and improves texture consistency, making perforated dehydrator trays ideal for high-quality candying processes.

Nonstick Sheet Caramelization

A nonstick baking sheet promotes even caramelization by allowing consistent heat distribution and easy candy release, preventing sticky residues that can disrupt texture. Perforated dehydrator trays enhance airflow, but their holes may cause uneven caramelization and difficulty in maintaining a smooth candy surface during the candying process.

Sugar Bloom Reduction

Using a perforated dehydrator tray for candying significantly reduces sugar bloom by allowing better airflow and moisture escape, preventing crystallization on the candy surface. In contrast, a solid baking sheet retains moisture, increasing the risk of uneven sugar crystallization and an undesirable bloom effect.

Drip-Through Crystallization

A perforated dehydrator tray enhances drip-through crystallization by allowing excess syrup and moisture to drain away, preventing soggy candy surfaces and promoting even drying. In contrast, a solid baking sheet retains moisture underneath the candy, often resulting in uneven crystallization and sticky textures.

Ventilated Tray Candying

Ventilated trays, such as perforated dehydrator trays, provide superior airflow during the candying process, ensuring even dehydration and preventing sogginess compared to traditional solid baking sheets. This enhanced ventilation optimizes moisture removal, resulting in crisp, uniformly candied fruits or vegetables with improved texture and flavor retention.

Even Heat Distribution Bakeware

A perforated dehydrator tray allows for superior airflow and even heat distribution, preventing hotspots and ensuring consistent candying results. In contrast, a baking sheet can cause uneven heating due to its solid surface, potentially leading to inconsistent texture and caramelization.

Candy Syrup Drainage Control

A perforated dehydrator tray offers superior candy syrup drainage control compared to a traditional baking sheet, allowing excess syrup to drip away and preventing candy from sitting in sticky pools. This design ensures even drying and enhances the texture of candied fruits or nuts by promoting better airflow and reducing sogginess.

Precision Drying Platform

A perforated dehydrator tray offers superior precision drying for candying by allowing uniform air circulation and consistent moisture removal, preventing sogginess and ensuring optimal texture. In contrast, a baking sheet lacks airflow control, which can lead to uneven drying and less predictable candy quality.

Baking Sheet vs Perforated Dehydrator Tray for candying. Infographic

cookingdiff.com

cookingdiff.com