Candying preserves food by slowly cooking it in sugar syrup to enhance sweetness and texture, while pressure candying speeds up the process using a pressure cooker, reducing cooking time significantly. Pressure candying maintains moisture more effectively and results in a firmer, more evenly cooked product compared to traditional candying. Both methods enhance flavor but differ in texture and preparation speed, making each suitable for different culinary needs.

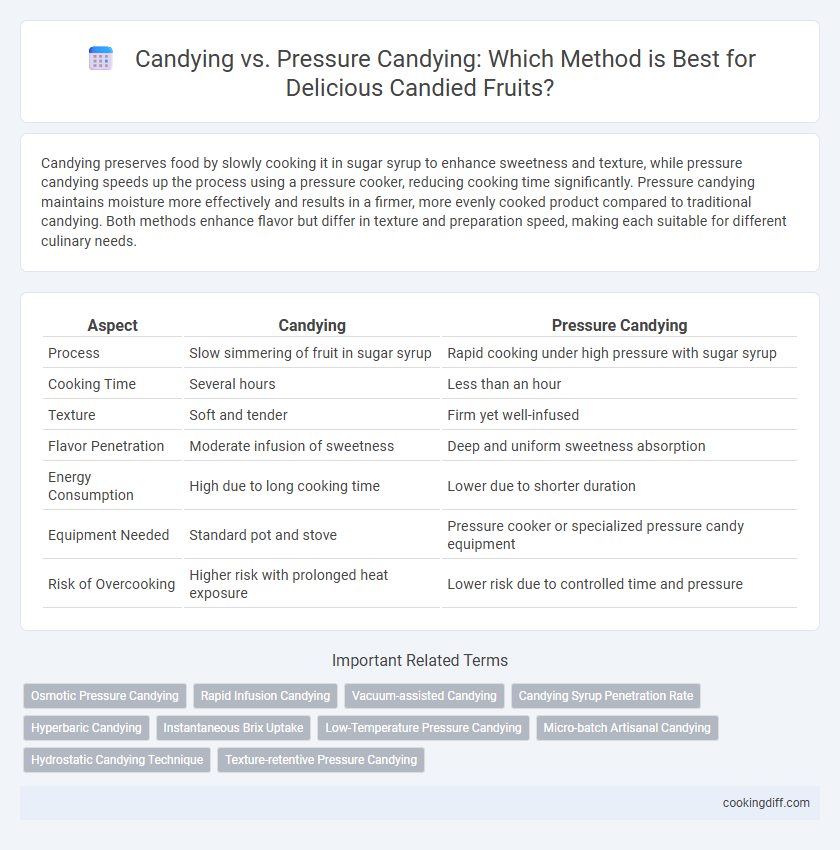

Table of Comparison

| Aspect | Candying | Pressure Candying |

|---|---|---|

| Process | Slow simmering of fruit in sugar syrup | Rapid cooking under high pressure with sugar syrup |

| Cooking Time | Several hours | Less than an hour |

| Texture | Soft and tender | Firm yet well-infused |

| Flavor Penetration | Moderate infusion of sweetness | Deep and uniform sweetness absorption |

| Energy Consumption | High due to long cooking time | Lower due to shorter duration |

| Equipment Needed | Standard pot and stove | Pressure cooker or specialized pressure candy equipment |

| Risk of Overcooking | Higher risk with prolonged heat exposure | Lower risk due to controlled time and pressure |

Introduction to Candying and Pressure Candying

Candying is a traditional cooking method that involves slowly cooking fruits or vegetables in sugar syrup to preserve and enhance their flavor and texture. Pressure candying uses a sealed pressure cooker to cook the produce at higher temperatures, significantly reducing the cooking time while intensifying the infusion of sugar. Both techniques aim to create sweet, preserved treats but differ mainly in duration and depth of flavor penetration.

Historical Background of Candying Techniques

Candying is an ancient preservation method dating back thousands of years, traditionally using sugar to draw out moisture from fruits to inhibit microbial growth. Pressure candying, a more recent innovation, incorporates controlled pressure to accelerate sugar infusion, reducing cooking times significantly.

- Traditional Candying Origins - Candying techniques trace back to ancient civilizations like Mesopotamia and Rome, where sugar preservation extended fruit shelf life.

- Evolution of Technology - The development of pressure candying emerged in the 20th century to optimize industrial candy production.

- Cultural Significance - Classic candying remains prevalent in culinary practices worldwide, emphasizing artisanal methods emphasizing gradual sugar absorption.

Principles of Traditional Candying

Traditional candying involves slow simmering of fruits in sugar syrup, allowing gradual penetration of sugar while preserving texture and flavor. The process relies on osmotic pressure to replace water in the fruit cells with sugar, preventing microbial growth and enhancing shelf life. This method emphasizes gentle heat and time to ensure even saturation and maintain the fruit's structural integrity.

The Science Behind Pressure Candying

Candying preserves fruits by soaking them in sugar syrup, allowing sugar to replace the water content through osmosis, while pressure candying accelerates this process by using high pressure and temperature. The science behind pressure candying involves increased pressure raising the boiling point of the syrup, enabling faster sugar infusion and reduced cooking time.

- Osmosis in Candying - Sugar syrup penetrates fruit cells gradually, replacing moisture with sugar to preserve texture and flavor.

- Pressure Effect - Elevated pressure increases boiling point, intensifying sugar absorption and softening fruit faster.

- Heat Transfer Efficiency - Pressure candying speeds heat penetration, ensuring even cooking and uniform candying.

Understanding the science behind pressure candying helps optimize texture and flavor while minimizing cooking duration.

Key Differences Between Candying and Pressure Candying

Candying involves slowly simmering fruit or vegetables in sugar syrup to preserve and infuse sweetness, while pressure candying uses a sealed pressure cooker to speed up the process by raising the boiling point of the syrup. The extended cooking time in traditional candying allows for deeper syrup absorption, enhancing flavor and texture.

Pressure candying significantly reduces cooking time and energy usage by applying pressure, making it ideal for bulk preparation or tougher produce. However, this method may result in slightly less intense flavor penetration compared to the gradual infusion achieved in conventional candying.

Flavor and Texture Outcomes

Candying preserves the natural flavors and results in a tender, slightly chewy texture, while pressure candying intensifies flavors and creates a firmer, more uniform texture due to higher temperature and pressure. The choice between methods significantly impacts the final taste complexity and mouthfeel of the candied product.

- Candying enhances subtle fruit flavors - Slow infusion allows natural sugars to penetrate, maintaining delicate taste nuances.

- Pressure candying boosts flavor intensity - High-pressure cooking accelerates sugar absorption, deepening sweetness and aroma.

- Texture varies with method - Traditional candying yields a soft, pliable texture whereas pressure candying produces a denser, chewier finish.

Efficiency and Time Comparison

Candying uses a slower infusion of sugar through prolonged boiling, allowing flavors to develop gradually, while pressure candying accelerates the process by utilizing high pressure to infuse sugar more rapidly. This method reduces cooking time significantly without compromising the texture and sweetness of the product.

Pressure candying can cut the cooking time by up to 50% compared to traditional candying methods, making it highly efficient for large-scale production. It ensures even sugar penetration due to consistent pressure and temperature control, resulting in uniform candy texture. Traditional candying methods are more energy-intensive and less suited for high-volume operations, highlighting pressure candying as the superior choice in time-sensitive cooking environments.

Equipment Needed for Each Method

| Method | Equipment Needed |

|---|---|

| Candying | Large saucepan or pot, slotted spoon, thermometer, and jar for storing candied fruit are essential for traditional candying. A heavy-bottomed pot prevents scorching during slow simmering of syrup and fruit. Accurate temperature control equipment helps ensure sugar consistency and candy texture. |

| Pressure Candying | Pressure cooker designed to handle high sugar content, racks to hold fruit above liquid, and heat-resistant gloves are required for pressure candying. This method uses sealed cooking under steam pressure, speeding up the infusion of syrup into the fruit. Precise pressure control is crucial to avoid overcooking and maintain fruit integrity. |

Applications in Modern Culinary Practices

How do candying and pressure candying differ in their applications within modern culinary practices? Traditional candying is ideal for delicate fruits and slow infusion of flavors, preserving texture and enhancing natural sweetness. Pressure candying accelerates the process, making it suitable for large-scale production and recipes requiring intensified flavor concentration.

Related Important Terms

Osmotic Pressure Candying

Osmotic pressure candying uses a high concentration sugar solution to draw moisture out of fruits or vegetables, enhancing flavor and preservation through controlled dehydration. This method contrasts with traditional candying by leveraging osmotic gradients to maintain texture and prevent over-saturation during cooking.

Rapid Infusion Candying

Rapid infusion candying uses high pressure to accelerate the absorption of sugar syrup into fruits, significantly reducing cooking time compared to traditional candying methods. Pressure candying enhances flavor penetration and texture preservation by forcing syrup into the fruit's cellular structure, while conventional candying relies on slow, passive diffusion.

Vacuum-assisted Candying

Vacuum-assisted candying accelerates the infusion of sugar syrup into fruits by reducing air pressure, enabling deeper flavor penetration and shorter processing times compared to traditional candying methods. This technique enhances texture and preserves natural color, setting it apart from pressure candying, which relies on high-pressure steam and often results in firmer, less flavorful produce.

Candying Syrup Penetration Rate

Candying penetration rates vary significantly between traditional soaking and pressure candying methods, with pressure candying enabling faster and deeper syrup absorption due to the application of high pressure that forces syrup molecules into the fruit's cellular structure. This accelerated syrup penetration enhances flavor uniformity and reduces processing time compared to conventional candying techniques where diffusion relies solely on osmosis.

Hyperbaric Candying

Hyperbaric candying uses high-pressure environments to accelerate sugar infiltration in fruits, enhancing flavor and texture more effectively than traditional candying methods. This process reduces cooking time and preserves nutritional value while achieving superior clarity and shelf stability in the final product.

Instantaneous Brix Uptake

Candying relies on gradual sugar absorption over several hours, resulting in slower Brix uptake and a less uniform texture, whereas Pressure Candying forces instantaneous Brix uptake by applying high pressure, significantly accelerating sugar penetration and enhancing flavor consistency. The advanced diffusion under pressure reduces processing time from days to minutes, optimizing both texture and sweetness in candied products.

Low-Temperature Pressure Candying

Low-temperature pressure candying uses controlled pressure and moderate heat to infuse sugar syrup into fruits, preserving texture and enhancing flavor without the drawbacks of high-temperature cooking. This method reduces cooking time significantly compared to traditional candying while maintaining nutritional content and producing a tender yet firm candy-coated product.

Micro-batch Artisanal Candying

Micro-batch artisanal candying emphasizes slow, precise sugar infusion to preserve natural flavors and textures, contrasting with pressure candying that accelerates the process using high heat and pressure but may compromise delicate aromas. This traditional technique allows greater control over crystallization, resulting in superior-quality candied fruits with complex, nuanced sweetness.

Hydrostatic Candying Technique

Hydrostatic candying technique uses water pressure to infuse sugar syrup into fruits more efficiently, resulting in enhanced flavor penetration and texture compared to traditional candying methods. This process reduces cooking time while maintaining the fruit's structural integrity and vibrant color, making it ideal for high-quality confectionery production.

Candying vs Pressure Candying for cooking. Infographic

cookingdiff.com

cookingdiff.com