A candy thermometer provides precise, direct temperature readings by being submerged in the hot sugar mixture, ensuring accurate control for perfect candy consistency. Laser infrared thermometers offer quick, non-contact temperature measurements but may be less reliable for candying because they measure surface temperature rather than the internal temperature of the mixture. For candy making, a candy thermometer is preferred due to its accuracy in monitoring the crucial boiling point stages.

Table of Comparison

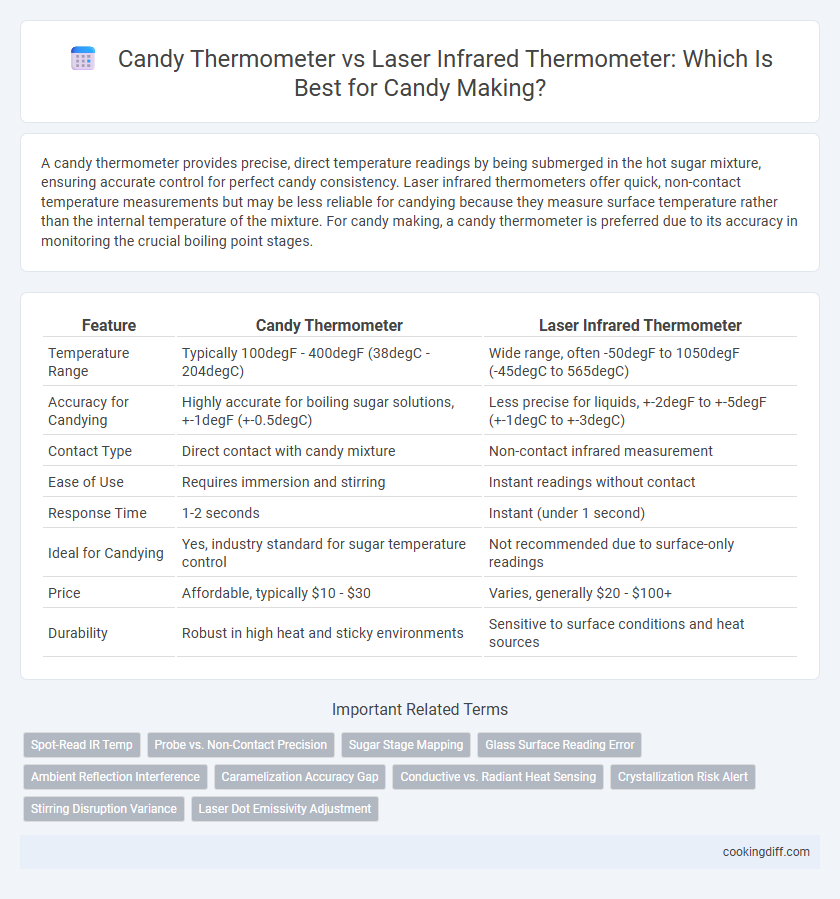

| Feature | Candy Thermometer | Laser Infrared Thermometer |

|---|---|---|

| Temperature Range | Typically 100degF - 400degF (38degC - 204degC) | Wide range, often -50degF to 1050degF (-45degC to 565degC) |

| Accuracy for Candying | Highly accurate for boiling sugar solutions, +-1degF (+-0.5degC) | Less precise for liquids, +-2degF to +-5degF (+-1degC to +-3degC) |

| Contact Type | Direct contact with candy mixture | Non-contact infrared measurement |

| Ease of Use | Requires immersion and stirring | Instant readings without contact |

| Response Time | 1-2 seconds | Instant (under 1 second) |

| Ideal for Candying | Yes, industry standard for sugar temperature control | Not recommended due to surface-only readings |

| Price | Affordable, typically $10 - $30 | Varies, generally $20 - $100+ |

| Durability | Robust in high heat and sticky environments | Sensitive to surface conditions and heat sources |

Introduction to Candying and Temperature Precision

Candying requires precise temperature control to achieve the perfect texture and consistency. A candy thermometer is designed to measure the sugar syrup's temperature accurately during the cooking process.

Laser infrared thermometers offer non-contact temperature readings but may lack the precision needed for candying due to surface temperature variation. For exact temperature monitoring in candy making, a traditional candy thermometer remains the preferred tool.

Overview: Candy Thermometer vs Laser Infrared Thermometer

Candy thermometers provide direct contact temperature readings essential for precise candy-making stages, while laser infrared thermometers measure surface temperature without contact, offering speed and convenience. Accuracy and usability differ significantly between these tools depending on the candying process requirements.

- Candy Thermometer - Measures internal temperature through direct contact, ensuring precise control over sugar stages like soft ball, hard crack, or caramelization.

- Laser Infrared Thermometer - Offers non-contact surface temperature readings, ideal for quick checks but less reliable for thick or boiling sugar mixtures.

- Application - Candy thermometers excel in recipes needing exact temperature control, while laser thermometers support general monitoring and safety from hot surfaces.

Choosing the right thermometer depends on the candy type and desired accuracy for temperature control.

How Candy Thermometers Work

Candy thermometers measure temperature by direct contact with the candy mixture, providing precise readings essential for achieving specific sugar stages. Laser infrared thermometers detect surface temperature without touching the candy but may offer less accuracy in thick or uneven mixtures.

- Direct Contact Measurement - Candy thermometers use a probe immersed in the mixture to accurately gauge internal temperature.

- Thermal Expansion Mechanism - Most candy thermometers rely on a liquid or bimetallic strip that expands or moves to indicate temperature levels.

- Infrared Sensing - Laser infrared thermometers detect radiant heat from the surface, useful for quick checks but less effective for dense sugar solutions.

How Laser Infrared Thermometers Function

Laser infrared thermometers measure temperature by detecting the infrared radiation emitted from a candy's surface without direct contact. This non-contact method provides quick readings essential for monitoring precise temperatures during the candying process.

- Infrared Detection - Uses sensor to capture emitted infrared energy from the candy's surface.

- Instant Readings - Offers rapid temperature measurement, minimizing heat loss in candy batches.

- Surface Temperature Focus - Measures only the outer layer temperature, which may differ from the candy's internal heat.

Accuracy and Reliability in Candying

Candy thermometers provide precise temperature readings directly in the sugar mixture, ensuring accurate control essential for achieving the correct candy stage. Their design allows for continuous monitoring, which is critical for consistency and reliability in candying processes.

Laser infrared thermometers measure surface temperature without contact, but may give less accurate readings due to reflective or uneven surfaces in candy mixtures. While convenient for quick checks, they lack the reliability of immersion thermometers in maintaining the exact temperatures needed for perfect candy texture.

Measuring Hot Sugar: Immersion vs Surface Readings

The candy thermometer provides precise immersion readings by directly measuring the temperature of hot sugar, ensuring accurate monitoring during the candying process. Laser infrared thermometers measure surface temperatures, which can lead to inaccurate readings due to the reflective or uneven nature of hot sugar surfaces. For candy making, immersion thermometers remain the preferred choice as they deliver consistent and reliable temperature data essential for achieving perfect sugar stages.

Ease of Use and Cleaning Considerations

Candy thermometers offer straightforward ease of use with clip-on features that attach directly to pots, allowing continuous temperature monitoring without needing to hold the device. Cleaning is simple since they are fully waterproof and can be rinsed under running water after use.

Laser infrared thermometers provide quick, contactless temperature readings ideal for surface monitoring but require careful aiming and may not measure the candy's internal temperature accurately. Cleaning involves wiping the sensor lens with a soft cloth, avoiding water exposure to prevent damage. The non-contact design reduces contamination risks, making it suitable for quick checks during candying processes.

Safety Aspects: Handling Hot Syrups

| Candy Thermometer | Designed to clip onto pots, allowing hands-free monitoring of hot sugar syrups, reducing risk of burns. |

| Laser Infrared Thermometer | Enables safe temperature readings from a distance without contact with hot surfaces or steam, minimizing burn hazards. |

| Safety Consideration | Candy thermometers require close proximity and careful handling, whereas laser infrared thermometers offer safer, non-contact temperature checks during candying. |

Cost and Availability Comparison

Candy thermometers are generally more affordable, ranging between $10 to $30, and widely available in most kitchen supply stores. Laser infrared thermometers tend to be pricier, often costing $50 or more, but offer non-contact temperature readings beneficial for precise candying. While candy thermometers are common and easy to purchase, laser infrared models might require specialty retailers or online ordering for availability.

Related Important Terms

Spot-Read IR Temp

Candy thermometers provide continuous temperature readings crucial for achieving precise sugar stages during candying, while laser infrared thermometers offer quick spot-read IR temp measurements ideal for monitoring surface temperatures without contact. Spot-read IR temp accuracy depends on emissivity settings and surface properties, making candy thermometers generally more reliable for consistent sugar temperature control in candying processes.

Probe vs. Non-Contact Precision

Candy thermometers feature a probe design that provides direct contact with sugar mixtures, ensuring accurate and consistent temperature readings critical for precise candying stages like soft ball or hard crack. Laser infrared thermometers offer non-contact temperature measurement ideal for quick surface checks but may lack the precise accuracy needed for exact sugar temperatures during candy preparation.

Sugar Stage Mapping

Candy thermometers provide precise temperature control directly in the sugar solution, crucial for accurately reaching specific sugar stages like soft ball (235degF-240degF) or hard crack (300degF-310degF). Laser infrared thermometers measure surface temperature quickly but may not reflect internal sugar temperature, risking inaccurate sugar stage mapping essential for perfect candy texture.

Glass Surface Reading Error

Candy thermometers provide direct contact temperature readings crucial for accurate sugar stage monitoring during candying, whereas laser infrared thermometers often produce inaccurate glass surface readings due to reflection and emissivity issues, leading to potential cooking errors. The emissivity of glass causes laser thermometers to underestimate actual candy temperature, making candy thermometers more reliable for precision in candying processes.

Ambient Reflection Interference

Candy thermometers provide precise temperature readings by direct contact with the candy mixture, preventing ambient reflection interference that often affects laser infrared thermometers. Laser infrared thermometers can give inaccurate readings during candying due to reflections from surrounding surfaces, making candy thermometers the preferred tool for consistent caramelization control.

Caramelization Accuracy Gap

Candy thermometers provide precise direct contact measurements essential for achieving accurate caramelization temperatures between 320degF and 350degF, ensuring optimal sugar melting without burning. Laser infrared thermometers, while convenient for quick surface readings, often fall short in capturing the precise internal sugar temperature, leading to potential inconsistencies in caramelization during candying.

Conductive vs. Radiant Heat Sensing

Candy thermometers measure temperature through direct contact, relying on conductive heat sensing to accurately gauge the sugar syrup's temperature essential for candying. Laser infrared thermometers use radiant heat sensing without contact, which can be less precise for candying due to the reflective nature of sugary surfaces affecting temperature readings.

Crystallization Risk Alert

Candy thermometers provide precise temperature readings critical for avoiding crystallization during candying by monitoring sugar concentration directly in the mixture. Laser infrared thermometers measure surface temperature only, increasing crystallization risk alerts due to potential inaccuracies in detecting the true internal temperature of the candy solution.

Stirring Disruption Variance

Candy thermometers provide accurate temperature readings while submerged in boiling sugar mixtures, minimizing stirring disruption, whereas laser infrared thermometers measure surface temperature and require multiple readings to account for variance caused by stirring and uneven heat distribution. The direct contact method of candy thermometers ensures consistent results during candying processes, unlike laser infrared thermometers that can yield fluctuating measurements due to stirring interference.

Candy Thermometer vs Laser Infrared Thermometer for Candying. Infographic

cookingdiff.com

cookingdiff.com