Candying preserves natural flavors by slowly infusing sugar syrup into the pet's treat, resulting in a sweet, subtle taste and a chewy texture. Vacuum infusion forces flavor deep into the treat using pressure changes, creating a stronger, more uniform taste but often altering the texture. Choosing candying enhances delicate, natural sweetness, while vacuum infusion delivers intense, evenly distributed flavors.

Table of Comparison

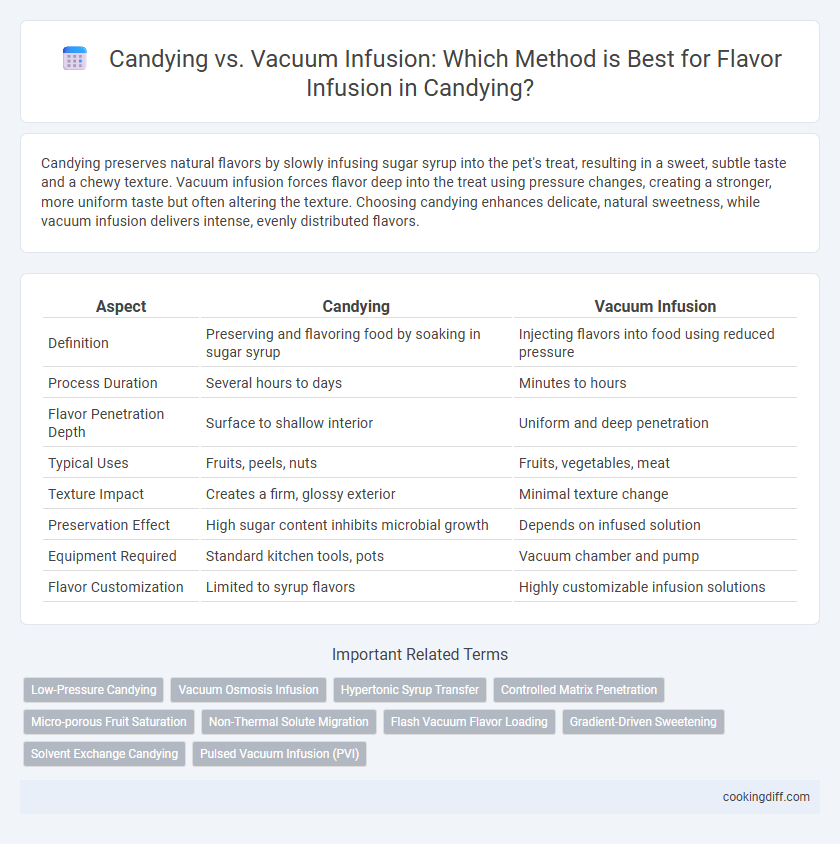

| Aspect | Candying | Vacuum Infusion |

|---|---|---|

| Definition | Preserving and flavoring food by soaking in sugar syrup | Injecting flavors into food using reduced pressure |

| Process Duration | Several hours to days | Minutes to hours |

| Flavor Penetration Depth | Surface to shallow interior | Uniform and deep penetration |

| Typical Uses | Fruits, peels, nuts | Fruits, vegetables, meat |

| Texture Impact | Creates a firm, glossy exterior | Minimal texture change |

| Preservation Effect | High sugar content inhibits microbial growth | Depends on infused solution |

| Equipment Required | Standard kitchen tools, pots | Vacuum chamber and pump |

| Flavor Customization | Limited to syrup flavors | Highly customizable infusion solutions |

Introduction to Flavor Infusion Techniques

Flavor infusion techniques are essential for enhancing the taste and aroma of culinary ingredients through controlled processes. Candying and vacuum infusion represent two distinct methods that manipulate sugar or liquid penetration to achieve desired flavor profiles.

- Candying - A traditional technique where fruits or vegetables are soaked in sugar syrup to replace moisture with sugary flavor and preserve texture.

- Vacuum Infusion - A modern method that uses reduced pressure to remove air and accelerate the absorption of flavored liquids into food matrices.

- Flavor Penetration - Candying predominantly infuses sweetness and preserves, while vacuum infusion allows rapid and uniform distribution of diverse flavor compounds.

What is Candying?

Candying is a preservation technique that involves soaking fruit in sugar syrup to enhance flavor and texture while extending shelf life. This method allows the fruit to absorb sweetness deeply, creating a chewy, flavorful treat.

- Flavor infusion through sugar saturation - Candying penetrates fruit with sugar, intensifying natural flavors and sweetness.

- Preservation by high sugar concentration - The high sugar content inhibits microbial growth, preserving the fruit longer.

- Comparison to vacuum infusion - Unlike vacuum infusion, candying relies on osmotic pressure and time for sugar absorption rather than mechanical extraction or pressure change.

Understanding Vacuum Infusion

Vacuum infusion is a technique that enhances flavor absorption by removing air from fruit cells, allowing syrups or flavoring liquids to penetrate more deeply and evenly. This method contrasts with candying, which relies on slow dehydration and sugar penetration without altering cell structure.

Understanding vacuum infusion requires grasping how reduced pressure expands fruit pores, facilitating rapid and uniform flavor distribution. The process shortens infusion time compared to traditional candying, preserving fresh texture and vibrant colors. It is particularly effective for delicate fruits where maintaining structural integrity is essential.

Key Differences: Candying vs Vacuum Infusion

What are the key differences between candying and vacuum infusion for flavor infusion? Candying involves soaking fruit in sugar syrup to preserve and infuse sweetness over time, while vacuum infusion uses reduced pressure to rapidly introduce flavors and liquids into food. Candying enhances texture and shelf life, whereas vacuum infusion prioritizes speed and deeper flavor penetration.

Flavor Intensity and Profile Comparison

Candied fruits develop a robust, concentrated sweetness and a complex flavor profile due to the prolonged sugar absorption process. The slow infusion enhances natural fruit notes while creating a glossy, textured exterior that intensifies overall flavor perception.

Vacuum infusion accelerates flavor penetration by removing air and allowing rapid absorption, resulting in a more uniform taste distribution. This method preserves fresh, vibrant fruit flavors but may yield a less intense sweetness compared to traditional candying.

Texture Impact: Which Method Wins?

| Method | Texture Impact |

|---|---|

| Candying | Candying creates a firm, crystallized texture by saturating fruit with sugar syrup, resulting in a chewy or slightly crunchy exterior that preserves the fruit's structure. |

| Vacuum Infusion | Vacuum infusion maintains a softer, more natural fruit texture by gently infusing flavors at low pressure, preventing the hardening effect of high sugar concentration. |

| Winner | For a crisp, preserved texture, candying excels; for retaining natural fruit softness while infusing flavor, vacuum infusion is superior. |

Efficiency and Time Considerations

Candying typically requires several hours to days to achieve optimal flavor infusion as the fruit or vegetable slowly absorbs the sugar syrup. Vacuum infusion significantly reduces the time needed, often completing the process within minutes by using pressure to force the infusion deeper and faster. Efficiency-wise, vacuum infusion offers a more consistent and controlled flavor penetration, making it ideal for large-scale or commercial operations.

Ingredient Suitability: Fruits, Vegetables, and More

Candying excels in preserving the natural texture and sweetness of fruits, while vacuum infusion penetrates flavors more rapidly into vegetables and porous ingredients. Fruits like citrus peels and cherries are ideal for candying, whereas vacuum infusion suits vegetables like cucumbers and mushrooms for deeper flavor absorption.

- Candying favors firm fruits - Ingredients with sturdy cell walls retain shape during the slow sugar infusion process.

- Vacuum infusion suits porous vegetables - Air removal allows flavor liquids to saturate hollow or spongy textures effectively.

- Versatility differs - Candying is mainly fruit-focused, whereas vacuum infusion applies broadly to both fruits and vegetables.

Choosing between candying and vacuum infusion depends on the ingredient's texture and desired flavor intensity.

Pros and Cons of Candying

Candying enhances flavor intensity by infusing fruits or vegetables with sugar, which also extends shelf life through natural preservation. This method can alter texture, making produce firmer and sometimes overly sweet compared to vacuum infusion, which maintains more natural moisture and texture. However, candying requires longer processing time and higher sugar content, potentially limiting health-conscious use.

Related Important Terms

Low-Pressure Candying

Low-pressure candying utilizes mild pressure to infuse flavors gradually, preserving the natural texture and enhancing sweetness without structural damage. Compared to vacuum infusion, low-pressure candying offers a gentler process that maintains product integrity while achieving deep, uniform flavor penetration.

Vacuum Osmosis Infusion

Vacuum osmosis infusion maximizes flavor penetration by using controlled pressure differentials to drive liquids deeply into the cellular structure of fruits, resulting in more uniform and intense taste compared to traditional candying techniques. Unlike candying, which relies on slow sugar absorption and dehydration, vacuum osmotic infusion preserves texture while accelerating the flavor infusion process through precise vacuum cycles.

Hypertonic Syrup Transfer

Candying relies on hypertonic syrup transfer to draw moisture out of the fruit and replace it with concentrated sugar, enhancing flavor and preservation. Vacuum infusion, by contrast, uses reduced pressure to speed syrup penetration but may result in less uniform sugar distribution compared to the gradual osmotic process in candying.

Controlled Matrix Penetration

Candying uses controlled matrix penetration by gradually replacing water in fruits with sugar syrup, preserving texture while infusing sweetness uniformly. Vacuum infusion accelerates flavor infusion by applying low pressure to force solutions into food pores, but may risk uneven penetration and textural changes compared to the gentle, diffusion-based candying process.

Micro-porous Fruit Saturation

Candying involves soaking fruit in concentrated sugar syrup, allowing micro-porous fruit saturation that preserves texture while infusing intense sweetness. Vacuum infusion accelerates flavor infusion by creating a pressure differential that forces flavors into the micro-pores, resulting in deeper saturation and enhanced taste profiles compared to traditional candying.

Non-Thermal Solute Migration

Candying relies on osmotic dehydration to infuse flavors by non-thermal solute migration through concentrated sugar solutions, preserving the fruit's texture without heat damage. Vacuum infusion enhances solute penetration by lowering pressure, accelerating flavor uptake while maintaining product integrity and minimizing thermal impact.

Flash Vacuum Flavor Loading

Flash Vacuum Flavor Loading (FVFL) offers a rapid and efficient alternative to traditional candying by utilizing vacuum infusion to penetrate flavors deeply and uniformly within seconds, preserving the integrity and moisture of the fruit. Unlike candying, which relies on prolonged soaking in sugary syrups, FVFL enhances flavor intensity and texture without excessive sugar absorption, making it ideal for high-quality confectionery applications.

Gradient-Driven Sweetening

Candying utilizes gradient-driven sweetening where sugar concentration gradually permeates the fruit, enhancing flavor infusion through osmotic pressure differences. Vacuum infusion accelerates this process by creating pressure differentials that force flavor compounds deeper and faster into the fruit's cellular structure, but may compromise the natural gradient essential for subtle taste development.

Solvent Exchange Candying

Solvent exchange candying enhances flavor infusion by replacing water in the food matrix with a flavored solvent, improving the penetration and retention of intense taste compounds compared to vacuum infusion. Unlike vacuum infusion, which relies on pressure differentials to introduce flavors, solvent exchange candying achieves deeper, more uniform flavor distribution through osmotic gradients without risking structural damage.

Candying vs Vacuum infusion for flavor infusion. Infographic

cookingdiff.com

cookingdiff.com