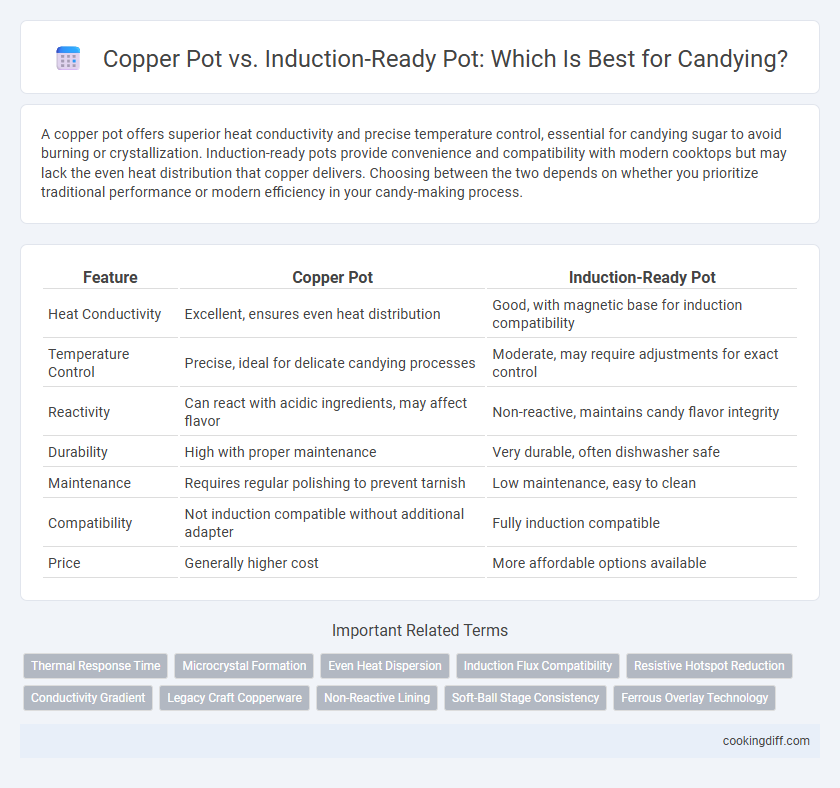

A copper pot offers superior heat conductivity and precise temperature control, essential for candying sugar to avoid burning or crystallization. Induction-ready pots provide convenience and compatibility with modern cooktops but may lack the even heat distribution that copper delivers. Choosing between the two depends on whether you prioritize traditional performance or modern efficiency in your candy-making process.

Table of Comparison

| Feature | Copper Pot | Induction-Ready Pot |

|---|---|---|

| Heat Conductivity | Excellent, ensures even heat distribution | Good, with magnetic base for induction compatibility |

| Temperature Control | Precise, ideal for delicate candying processes | Moderate, may require adjustments for exact control |

| Reactivity | Can react with acidic ingredients, may affect flavor | Non-reactive, maintains candy flavor integrity |

| Durability | High with proper maintenance | Very durable, often dishwasher safe |

| Maintenance | Requires regular polishing to prevent tarnish | Low maintenance, easy to clean |

| Compatibility | Not induction compatible without additional adapter | Fully induction compatible |

| Price | Generally higher cost | More affordable options available |

Understanding Candying: The Importance of Cookware

Copper pots offer superior heat conductivity, allowing for precise temperature control essential in candying processes to prevent sugar from burning or crystallizing. Induction-ready pots provide efficient, even heating and durability, but may lack the rapid response time of copper when adjusting temperatures. Choosing the right cookware significantly impacts the texture and consistency of candies, ensuring optimal results in sugar cooking.

Copper Pots: Classic Choice for Candying

Copper pots are a classic choice for candying due to their superior thermal conductivity, which ensures even heat distribution and precise temperature control. This is crucial for achieving the perfect sugar consistency without burning or crystallizing.

The responsiveness of copper pots allows cooks to quickly adjust heat, reducing the risk of scorching delicate sugar mixtures. Their excellent heat retention maintains a steady temperature, essential for candying processes like making caramel or nougat. Although maintenance requires regular polishing to prevent tarnishing, the benefits for candying precision make copper pots highly valued by professionals.

Induction-Ready Pots: Modern Precision in Candy Making

| Induction-Ready Pot Material | Stainless steel or aluminum layered with magnetic steel |

| Heat Distribution | Even and rapid, minimizing hot spots for consistent candy textures |

| Temperature Control | Compatible with induction cooktops offering precise temperature adjustments crucial for sugar crystallization |

| Maintenance | Durable and easy to clean without the need for seasoning, resisting corrosion during acidic candying processes |

| Energy Efficiency | Direct electromagnetic heat transfer reduces energy use and cooking time |

Heat Distribution: Copper vs Induction-Ready Pots

Copper pots provide superior heat distribution due to copper's excellent thermal conductivity, ensuring even heating during candying. Induction-ready pots typically have a stainless steel base with an aluminum core, offering a balance of heat distribution and compatibility with induction cooktops.

- Copper's Thermal Conductivity - Copper's conductivity is approximately 401 W/m*K, allowing rapid and uniform heat transfer.

- Induction-Ready Pot Construction - These pots use a magnetic base to activate induction burners and often include an aluminum core for heat distribution.

- Heat Distribution Efficiency - Copper pots excel in preventing hot spots critical for precise candying, while induction-ready pots provide moderate and consistent heat.

Copper pots remain the top choice for candying when precise heat control and even distribution are paramount.

Temperature Control and Consistency

Copper pots offer superior temperature control due to their rapid and even heat conduction, making them ideal for candying where precise temperature is critical. Their ability to quickly adjust heat prevents sugar from burning or crystallizing, ensuring consistent results.

Induction-ready pots provide efficient heating with fast response times but may have less uniform heat distribution compared to copper. While they work well for candying, slight temperature fluctuations can impact the smoothness and texture of the final candy product.

Reactivity with Sugar and Ingredients

Copper pots offer superior heat conductivity and precise temperature control, crucial for candying sugar without burning. Their natural reactivity with acidic ingredients can enhance flavor development but may require lining to prevent unwanted chemical reactions.

Induction-ready pots, typically made of stainless steel or aluminum with magnetic bases, provide even heating but lack the chemical reactivity of copper. These pots are non-reactive with sugar and most ingredients, ensuring consistent results without altering taste.

Durability and Maintenance Considerations

Copper pots offer exceptional heat conductivity but require regular polishing to prevent tarnishing, impacting long-term durability. Induction-ready pots, typically made from stainless steel or aluminum, provide robust construction with minimal maintenance needs, ideal for frequent use.

- Copper Pot Durability - Highly durable if maintained properly, but prone to dents and scratches without careful handling.

- Maintenance for Copper Pots - Requires frequent cleaning and polishing to maintain appearance and prevent oxidation.

- Induction-Ready Pot Advantages - Built for durability with corrosion-resistant materials that need less upkeep and resist wear.

Cost Comparison: Investment and Longevity

Copper pots require a higher initial investment but offer exceptional heat conductivity and durability, often lasting decades with proper care. Induction-ready pots are more affordable upfront and compatible with modern cooktops, though their longevity varies depending on the material quality.

- High Initial Cost for Copper Pots - Copper cookware typically costs significantly more due to premium materials and craftsmanship.

- Affordable Induction-Ready Options - Induction pots generally provide budget-friendly alternatives that work efficiently on induction stoves.

- Longevity Advantage of Copper - Copper pots can remain functional and efficient for many years, justifying the higher initial price over time.

User Experience: Ease of Handling and Safety

Copper pots offer superior heat conductivity, allowing precise temperature control crucial for candying, enhancing user experience through consistent results. Induction-ready pots provide easy handling with lightweight designs and safety features like flat bottoms for stability on induction cooktops. Both options prioritize safety, but copper pots require attentive maintenance to prevent overheating, while induction pots offer automatic temperature regulation for safer candy preparation.

Related Important Terms

Thermal Response Time

Copper pots offer superior thermal response time during candying, allowing precise temperature control essential for sugar crystallization and caramelization. Induction-ready pots, typically made of stainless steel with magnetic bases, have slower heat adjustments, potentially leading to uneven cooking or burn spots when cooking delicate sugar syrups.

Microcrystal Formation

Copper pots provide superior temperature control crucial for preventing microcrystal formation in candying, resulting in smoother, clearer candies. Induction-ready pots, while efficient and compatible with modern cooktops, often lack the precise heat distribution needed to avoid unwanted crystallization during the candying process.

Even Heat Dispersion

Copper pots provide superior even heat dispersion essential for candying, preventing hot spots and ensuring consistent sugar crystallization. Induction-ready pots, often made with layered stainless steel and aluminum cores, offer good but less precise heat distribution, which can affect delicate candy textures.

Induction Flux Compatibility

Induction-ready pots are designed with magnetic materials that ensure efficient heat transfer and precise temperature control essential for candying, while traditional copper pots lack this compatibility, requiring additional flux to work on induction cooktops. Using an induction flux with copper pots may improve conductivity but often results in uneven heating, making induction-ready pots the superior choice for consistent candying results.

Resistive Hotspot Reduction

Copper pots offer superior thermal conductivity, minimizing resistive hotspots during candying by evenly distributing heat, which prevents scorching and ensures consistent syrup texture. Induction-ready pots, often constructed with layered stainless steel bases, provide efficient heating but may exhibit slight unevenness in heat distribution, potentially increasing the risk of localized overheating in delicate candying processes.

Conductivity Gradient

Copper pots offer superior conductivity gradient compared to induction-ready pots, enabling more precise temperature control essential for candying delicate sugar mixtures. This enhanced thermal conductivity ensures even heat distribution, preventing scorching and allowing candy to reach exact stages crucial for perfect texture and consistency.

Legacy Craft Copperware

Legacy Craft Copperware offers superior heat conductivity in their copper pots, ensuring even temperature distribution crucial for precise candying processes. Induction-ready pots, while compatible with modern stovetops, often lack the responsive temperature control that copper provides, making copper pots the preferred choice for achieving consistent caramelization and sugar crystallization.

Non-Reactive Lining

Copper pots with a non-reactive lining, such as stainless steel or tin, are ideal for candying as they ensure even heat distribution without chemical reactions that can alter flavor. Induction-ready pots often have stainless steel linings, which provide non-reactive surfaces suitable for precise temperature control essential in candying.

Soft-Ball Stage Consistency

Copper pots provide superior heat conductivity and precise temperature control, ensuring consistent soft-ball stage results critical for candying. Induction-ready pots, although energy-efficient, often heat unevenly, potentially causing fluctuations in sugar temperature and impacting candy texture.

Copper Pot vs Induction-Ready Pot for candying. Infographic

cookingdiff.com

cookingdiff.com