Copper jam pans provide superior heat conductivity, ensuring even cooking and preventing hot spots, which is essential for candying delicate items without burning. Pot materials like stainless steel or aluminum offer durability but may heat unevenly, requiring more attentive stirring to avoid scorching. Choosing a copper jam pan enhances precision and results in a consistent, high-quality candying process.

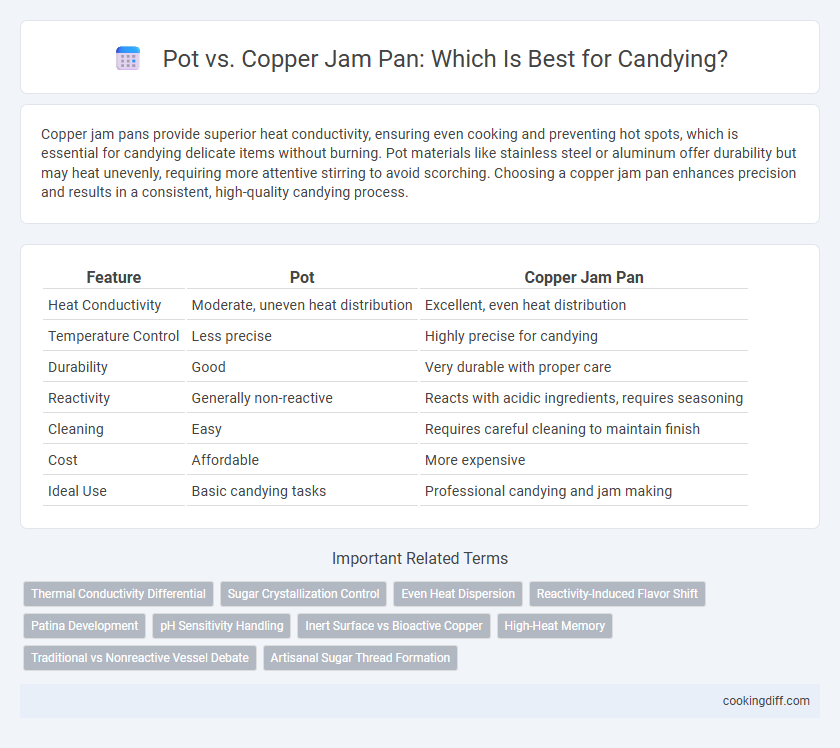

Table of Comparison

| Feature | Pot | Copper Jam Pan |

|---|---|---|

| Heat Conductivity | Moderate, uneven heat distribution | Excellent, even heat distribution |

| Temperature Control | Less precise | Highly precise for candying |

| Durability | Good | Very durable with proper care |

| Reactivity | Generally non-reactive | Reacts with acidic ingredients, requires seasoning |

| Cleaning | Easy | Requires careful cleaning to maintain finish |

| Cost | Affordable | More expensive |

| Ideal Use | Basic candying tasks | Professional candying and jam making |

Understanding Candying: The Basics

Choosing between a pot and a copper jam pan significantly impacts the candying process due to heat conductivity differences; copper pans offer superior and even heat distribution, reducing the risk of scorching sugar. Pots made from stainless steel or aluminum may require closer attention to temperature control to prevent uneven cooking and crystallization. Understanding these material properties is essential for achieving the perfect candy texture and consistent results in candying.

Key Features of a Traditional Pot

Traditional pots used in candying offer excellent heat distribution essential for even cooking and preventing scorching. Their durability and compatibility with various heat sources make them a reliable choice for extended candying processes.

- Superior Heat Retention - Traditional pots maintain consistent temperatures needed for precise candying stages.

- Durable Construction - Made from robust materials that withstand high heat and frequent use without warping.

- Versatile Compatibility - Suitable for use on gas, electric, and induction stovetops, enhancing convenience.

Advantages of Using a Copper Jam Pan

Copper jam pans provide superior heat conductivity, ensuring even cooking and preventing hot spots that can burn candy. Their excellent thermal response allows precise temperature control, crucial for achieving the perfect candy consistency. Copper's durability and resistance to corrosion make it a long-lasting investment for dedicated candy makers.

Heat Distribution: Pot vs Copper Jam Pan

Copper jam pans offer superior heat distribution compared to regular pots, allowing for more even cooking and reducing the risk of scorching during candying. The high thermal conductivity of copper ensures that heat spreads quickly and uniformly across the pan surface.

In contrast, standard pots, typically made of stainless steel or aluminum, often have uneven heat distribution, causing hot spots that can lead to inconsistent candy texture. Using a copper pan enhances temperature control, which is crucial for achieving perfect candying results.

Reactivity and Flavor Impact

Does the choice between a pot and a copper jam pan affect the reactivity and flavor during candying? Copper jam pans react less with acidic ingredients, preserving the natural fruit flavors and preventing metallic taste. Stainless steel pots, while non-reactive, may not conduct heat as evenly as copper, potentially impacting the consistency of the candying process.

Cleaning and Maintenance Guide

Cleaning and maintaining pots versus copper jam pans require different approaches due to their material properties. Copper pans need careful polishing to prevent tarnish, while pots are generally easier to clean with standard dish soap.

- Copper requires gentle cleaning - Use non-abrasive cleaners and a soft cloth to maintain shine and avoid scratches.

- Pots handle high temperatures - They can be scrubbed more vigorously without risk of damage, making residue removal easier.

- Copper needs drying immediately - Prevent water spots and corrosion by drying thoroughly after washing.

Following these cleaning and maintenance tips ensures longevity and optimal performance for both cookware types in candying.

Cost Comparison: Which Is More Affordable?

Pot jam pans generally offer a more budget-friendly option compared to copper jam pans, making them accessible for everyday candying. Copper jam pans, while pricier, provide superior heat conductivity that can improve candying results.

- Cost Efficiency - Pot jam pans tend to be less expensive, suitable for hobbyists and beginners.

- Investment Value - Copper jam pans, though costly, are durable and enhance temperature control in candying.

- Long-Term Expense - Choosing a copper pan may reduce cooking errors, potentially saving money on wasted ingredients.

Best Practices for Candying in Each Vessel

Using a copper jam pan ensures even heat distribution, preventing hot spots that can cause burning during candying. Its excellent thermal conductivity allows precise temperature control, essential for achieving the perfect candy texture.

Pot materials like stainless steel are durable but may require more attentive heat management to avoid scorching. For best results in copper pans, always stir gently and avoid rapid temperature changes to maintain the pan's integrity. With stainless steel pots, use a heavy-bottomed design and moderate heat to prevent sticking and ensure consistent sugar crystallization.

Professional Insights: Chef Preferences

| Professional chefs generally prefer copper jam pans for candying due to their superior heat conductivity, allowing precise temperature control critical in sugar work. Pot materials like stainless steel often cause uneven heating, risking caramelization or burning. Copper pans' responsiveness ensures consistent texture and color in candying processes, making them a top choice in professional kitchens. |

Related Important Terms

Thermal Conductivity Differential

Copper jam pans exhibit superior thermal conductivity, allowing for even heat distribution and precise temperature control essential in candying, whereas pots made from materials with lower thermal conductivity can cause uneven cooking or hot spots, compromising the candy's texture and consistency. The high thermal conductivity of copper ensures rapid response to temperature changes, reducing the risk of burning and promoting a uniform candying process.

Sugar Crystallization Control

Copper jam pans provide superior thermal conductivity compared to traditional pots, enabling precise temperature control essential for preventing premature sugar crystallization during candying. The even heat distribution in copper pans ensures consistent syrup texture and inhibits graininess, making them ideal for achieving smooth, high-quality candy finishes.

Even Heat Dispersion

Copper jam pans provide superior even heat dispersion compared to pots, ensuring consistent temperature control crucial for candying. This even heating prevents hotspots, reducing the risk of burning sugar and resulting in smoother, well-cooked candy.

Reactivity-Induced Flavor Shift

Copper jam pans offer superior heat conductivity but can induce a reactivity-induced flavor shift by interacting with acidic fruits during candying, potentially altering the taste and color of the final product. In contrast, non-reactive pots, such as stainless steel, prevent flavor changes by avoiding metal-food reactions, preserving the original fruit flavor and ensuring consistent candying results.

Patina Development

Copper jam pans promote better patina development during candying by allowing superior heat conductivity and even temperature distribution, which enhances flavor through controlled caramelization. In contrast, standard pots often lack the reactive surface needed for patina buildup, resulting in less nuanced taste profiles and uneven cooking.

pH Sensitivity Handling

Copper jam pans offer superior heat conductivity and precise temperature control essential for candying, but their reactive nature can alter the pH of acidic ingredients, affecting the final texture and flavor. Stainless steel pots are non-reactive, maintaining consistent pH levels during candying, which is crucial for achieving the desired consistency and preventing unwanted chemical reactions.

Inert Surface vs Bioactive Copper

Copper jam pans provide superior heat conductivity for even cooking, but their bioactive surface reacts with acidic ingredients, enhancing flavor and color development during candying. In contrast, pots with inert surfaces like stainless steel prevent chemical reactions, ensuring neutral taste preservation and easier maintenance.

High-Heat Memory

Copper jam pans excel in candying due to their superior high-heat memory, allowing for even and consistent temperature retention crucial for precise sugar crystallization. In contrast, standard pots typically have lower heat retention, which can lead to uneven cooking and affect the texture and quality of the candy.

Traditional vs Nonreactive Vessel Debate

Copper jam pans, favored in traditional candying for their superior heat conductivity and even cooking, facilitate precise temperature control critical for achieving ideal sugar crystallization; however, nonreactive pots like stainless steel offer durability and resistance to acidic ingredients without imparting metallic flavors. The debate centers on balancing the authentic artisanal qualities of copper with the practical benefits and ease of maintenance found in nonreactive vessels during candying processes.

Pot vs Copper Jam Pan for candying. Infographic

cookingdiff.com

cookingdiff.com