Candying citrus peel involves simmering the peel in sugar syrup until it becomes tender and sweet, while dehydration-infused candying removes moisture by drying the peel after candying, resulting in a chewier texture and more concentrated flavors. Dehydration-infused candying enhances shelf life and intensifies the citrus aroma, making it ideal for gourmet applications. Traditional candying offers a softer, more succulent bite, perfect for immediate consumption or use in baking.

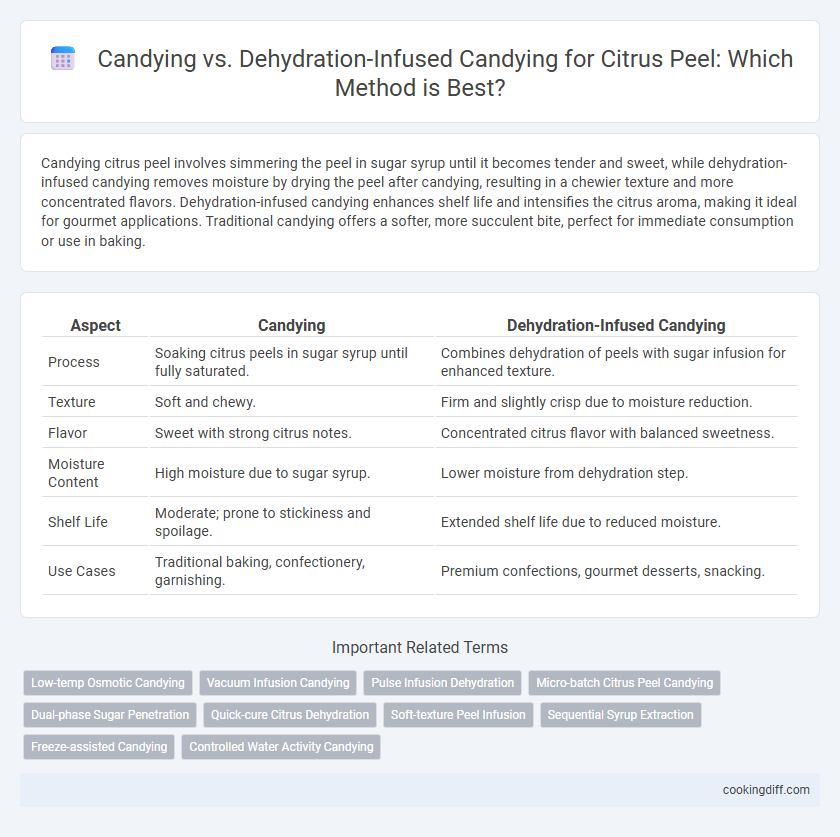

Table of Comparison

| Aspect | Candying | Dehydration-Infused Candying |

|---|---|---|

| Process | Soaking citrus peels in sugar syrup until fully saturated. | Combines dehydration of peels with sugar infusion for enhanced texture. |

| Texture | Soft and chewy. | Firm and slightly crisp due to moisture reduction. |

| Flavor | Sweet with strong citrus notes. | Concentrated citrus flavor with balanced sweetness. |

| Moisture Content | High moisture due to sugar syrup. | Lower moisture from dehydration step. |

| Shelf Life | Moderate; prone to stickiness and spoilage. | Extended shelf life due to reduced moisture. |

| Use Cases | Traditional baking, confectionery, garnishing. | Premium confections, gourmet desserts, snacking. |

Introduction to Candying and Dehydration-Infused Candying

Candiying is a preservation method that involves soaking citrus peels in sugar syrup to enhance flavor and texture while extending shelf life. Dehydration-infused candying combines traditional candying techniques with controlled dehydration, resulting in a more intense citrus flavor and a chewier texture. This hybrid approach reduces moisture content more efficiently, improving product stability and reducing sugar absorption compared to conventional candying.

Understanding Traditional Candying Methods

Traditional candying involves simmering citrus peels in sugar syrup until they become tender and saturated with sweetness. This method preserves the natural texture and flavor of the peel but can result in a softer, less intense citrus experience compared to advanced techniques.

- Traditional Candying - Citrus peels are slowly cooked in gradually concentrated sugar syrup to replace moisture with sugar.

- Flavor Development - The prolonged simmering enhances sweetness while mellowing the citrus sharpness.

- Texture Outcome - Results in tender, pliable peels with a glossy finish typical of classic candied citrus treats.

Dehydration-Infused Candying: Modern Approach

Dehydration-infused candying of citrus peel integrates advanced dehydration techniques to enhance flavor concentration and texture retention. This modern approach reduces moisture content more efficiently than traditional methods, resulting in a chewier and more flavorful product.

By infusing dehydration during candying, the citrus peel maintains a vibrant color and nutrient profile, outperforming standard candying processes. This technique also accelerates production time while preserving essential oils that contribute to the peel's aromatic complexity.

Key Differences Between Candying and Dehydration-Infused Candying

Candying involves soaking citrus peels in sugar syrup until fully saturated, resulting in a sweet, chewy texture with preserved moisture. Dehydration-infused candying combines this process with controlled drying, creating a firmer texture and intensified citrus flavor by removing excess moisture while retaining sugar infusion.

The key difference lies in moisture content; traditional candying retains high moisture levels, while dehydration-infused candying reduces water content for longer shelf life and crunchier results. Both methods enhance citrus peel preservation but cater to distinct culinary applications based on texture and flavor concentration preferences.

Impact on Flavor and Texture of Citrus Peels

Candied citrus peels have a rich, intense sweetness and a tender chew, while dehydration-infused candying preserves a more natural zest and creates a slightly firmer texture. The dehydration process enhances citrus oils, leading to a more pronounced aromatic profile and a delicate balance between sweetness and bitterness.

- Flavor Enhancement - Dehydration-infused candying intensifies natural citrus flavors by concentrating aromatic oils.

- Texture Variation - Traditional candying produces a soft, pliable peel, whereas dehydration results in a firmer, less sticky texture.

- Sweetness Balance - Candying typically yields a sweeter peel, while dehydration-infused methods maintain citrus bitterness for complexity.

The choice between candying methods influences both the sensory experience and culinary application of citrus peel confections.

Preparation Process: Step-by-Step Comparison

Candying citrus peel involves simmering the peel in sugar syrup until translucent, whereas dehydration-infused candying combines brief candying with controlled drying to enhance texture and flavor. Both methods require precise preparation steps to preserve the peel's natural oils and achieve the desired sweetness.

- Preparation of Peel - Peel is cleaned and blanched to reduce bitterness before candying or dehydration.

- Sugar Infusion - Traditional candying soaks peel in gradually concentrated syrup; dehydration-infused candying uses brief syrup immersion followed by drying.

- Drying Process - Candying allows natural drying; dehydration-infused candying employs specialized dehydrators to control moisture content and texture.

Equipment and Ingredients Required for Each Method

What equipment and ingredients differentiate candying from dehydration-infused candying for citrus peel? Traditional candying requires a saucepan, stove, sugar, water, and fresh citrus peels for simmering in a sugar syrup. Dehydration-infused candying involves a dehydrator or low-temperature oven and often uses a concentrated syrup or natural fruit sugars to enhance flavor retention during drying.

Preservation and Shelf-Life Considerations

Candying preserves citrus peel by saturating it with sugar, creating a barrier that inhibits microbial growth and moisture loss, extending shelf life up to several months. Dehydration-infused candying combines drying techniques to reduce water activity further, enhancing preservation by slowing enzymatic reactions and preventing spoilage for up to a year. Both methods optimize shelf stability, but dehydration-infused candying offers superior longevity and texture retention for citrus peel products.

Culinary Uses of Candyed vs. Dehydration-Infused Citrus Peels

Candying citrus peels results in a sweet, tender texture ideal for garnishing desserts and enhancing baked goods with a rich citrus flavor. Dehydration-infused candying produces a chewier, more concentrated peel, perfect for snacking or as a vibrant addition to cocktail recipes.

In culinary uses, candyed citrus peels are commonly incorporated into cakes, pastries, and chocolate confections, where their soft texture easily blends with other ingredients. Dehydration-infused candying, by contrast, preserves the zest's natural oils and imparts a more intense aroma, making it ideal for infusing syrups and liquors. Both methods elevate dishes but cater to different texture preferences and flavor intensities in recipes.

Related Important Terms

Low-temp Osmotic Candying

Low-temp osmotic candying preserves the vibrant color and natural aroma of citrus peel by using a controlled, low-temperature sugar infusion process that minimizes cellular damage compared to traditional dehydration methods. This technique enhances flavor retention and texture, producing a tender, less dense peel with superior shelf stability and reduced nutrient loss.

Vacuum Infusion Candying

Vacuum infusion candying enhances citrus peel by rapidly infusing sugar syrup under reduced pressure, preserving vibrant color and intense flavor more effectively than traditional dehydration-infused candying methods. This technique minimizes cellular damage and moisture loss, resulting in a tender texture and prolonged shelf life compared to conventional drying processes.

Pulse Infusion Dehydration

Pulse Infusion Dehydration enhances candying of citrus peel by rapidly removing moisture while infusing sweeteners and flavors, resulting in a more vibrant texture and intensified taste compared to traditional candying. This method preserves the peel's natural oils and color with improved shelf life and reduced processing time, making it a superior choice for high-quality citrus confections.

Micro-batch Citrus Peel Candying

Micro-batch citrus peel candying enhances flavor retention and texture by carefully infusing sugar syrup, whereas dehydration-infused candying removes moisture more rapidly but may compromise the peel's natural aroma and juiciness. Controlled candied peel production in micro-batches ensures consistent syrup absorption, preserving essential oils and vibrant citrus notes for superior gourmet quality.

Dual-phase Sugar Penetration

Candying citrus peel involves soaking the fruit in sugar syrup to replace moisture with sugar, whereas dehydration-infused candying employs a drying step that enhances sugar penetration by creating porous peel structures. Dual-phase sugar penetration in dehydration-infused candying improves texture and flavor infusion by allowing sugars to infiltrate deeper during both syrup immersion and subsequent drying stages.

Quick-cure Citrus Dehydration

Quick-cure citrus dehydration enhances traditional candying by rapidly removing moisture while preserving the peel's vibrant flavor and texture, unlike standard candying, which relies on slow sugar infusion that can result in a softer peel. This method intensifies citrus aroma and extends shelf life, making it ideal for producing high-quality dehydrated citrus peel snacks with a more pronounced zing and firmer bite.

Soft-texture Peel Infusion

Candying preserves citrus peel by infusing it with sugar syrup, resulting in a soft texture that retains moisture and flavor, whereas dehydration-infused candying removes moisture first, producing a firmer, chewier peel with concentrated citrus notes. Soft-texture peel infusion enhances the candying process by allowing deeper sugar penetration, creating a tender and flavorful treat compared to the drier, denser texture yielded by dehydration methods.

Sequential Syrup Extraction

Sequential syrup extraction in candying maximizes flavor retention and sugar absorption by gradually increasing syrup concentration, enhancing the citrus peel's texture and sweetness. In contrast, dehydration-infused candying relies on moisture removal to concentrate flavors but may result in less uniform syrup penetration compared to the layered infusion process.

Freeze-assisted Candying

Freeze-assisted candying enhances the infusion of sugar and flavors into citrus peels by creating microfractures during freezing, which increases permeability compared to traditional dehydration-infused candying. This method preserves the peel's natural texture and intensifies sweetness while reducing processing time and moisture loss, offering a superior alternative for high-quality candied citrus products.

Candying vs Dehydration-infused Candying for citrus peel. Infographic

cookingdiff.com

cookingdiff.com