Metal trays offer excellent heat conduction for even cooking during candying, making them ideal for quick temperature adjustments. Marble slabs provide a smooth, non-stick surface that cools evenly and prevents sugar from crystallizing too rapidly. Choosing between metal trays and marble slabs depends on whether precise temperature control or slow, consistent cooling is prioritized.

Table of Comparison

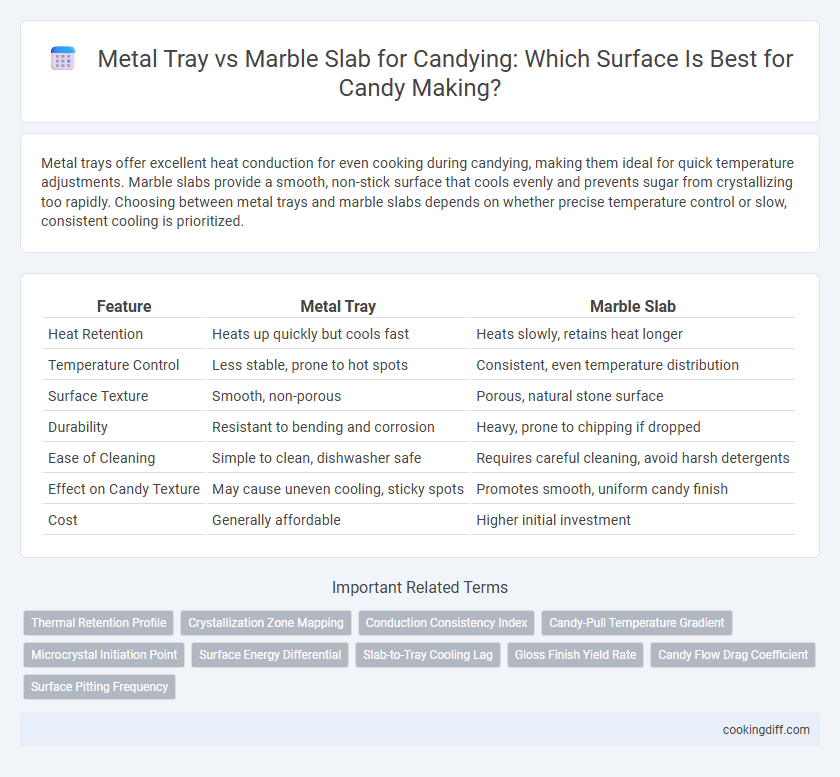

| Feature | Metal Tray | Marble Slab |

|---|---|---|

| Heat Retention | Heats up quickly but cools fast | Heats slowly, retains heat longer |

| Temperature Control | Less stable, prone to hot spots | Consistent, even temperature distribution |

| Surface Texture | Smooth, non-porous | Porous, natural stone surface |

| Durability | Resistant to bending and corrosion | Heavy, prone to chipping if dropped |

| Ease of Cleaning | Simple to clean, dishwasher safe | Requires careful cleaning, avoid harsh detergents |

| Effect on Candy Texture | May cause uneven cooling, sticky spots | Promotes smooth, uniform candy finish |

| Cost | Generally affordable | Higher initial investment |

Introduction: Choosing the Right Surface for Candying

Selecting the ideal surface for candying significantly impacts the texture and cooling process of the final product. Metal trays and marble slabs each offer unique thermal properties that influence candy preparation efficiency.

- Metal Trays - Provide rapid heat conduction ideal for quick cooling and shaping of candies.

- Marble Slabs - Maintain a consistent cool temperature, preventing premature sticking and promoting smooth candy surfaces.

- Surface Reactivity - Marble is non-reactive, preserving flavor integrity, while metal trays may occasionally react with acidic ingredients.

Overview: Metal Tray and Marble Slab Defined

Metal trays used in candying are typically made of stainless steel or aluminum, offering durability and even heat distribution essential for consistent cooking. Marble slabs provide a naturally cool, non-stick surface ideal for pouring and setting sugar mixtures, which aids in rapid cooling and shaping. Choosing between a metal tray and marble slab depends on the specific candying technique and temperature control needed for optimal results.

Heat Distribution: Metal vs Marble During Candy Making

| Material | Heat Distribution | Impact on Candying |

|---|---|---|

| Metal Tray | Conducts heat quickly and evenly, creating consistent temperature across the surface. | Promotes faster setting times and reduces the risk of uneven crystallization during candy making. |

| Marble Slab | Slower heat conduction with natural cold retention, leading to gradual cooling. | Allows controlled crystallization and superior texture refinement in delicate candy recipes. |

Surface Temperature Control for Candying

Metal trays heat up quickly and retain heat unevenly, posing challenges for precise surface temperature control during candying. Their rapid heat conduction can cause hot spots, which may lead to inconsistent candy texture and crystallization issues.

Marble slabs offer superior temperature stability and distribute heat evenly, making them ideal for controlled surface cooling in candying processes. The natural coolness of marble helps maintain optimal candying temperatures, reducing the risk of overheating and ensuring a smooth final product.

Impact on Candy Texture and Finish

Using a metal tray in candying promotes faster cooling due to its high thermal conductivity, which can result in a crisper texture and shinier finish. The rapid heat dissipation helps set the candy evenly, minimizing stickiness and improving overall smoothness.

A marble slab provides a cooler, slower cooling surface that allows candy to harden more gradually, enhancing a chewier texture and often a matte finish. Its lower heat transfer rate aids in preventing cracking but may require longer setting times to achieve optimal results.

Cleaning and Maintenance: Which Is Easier?

Metal trays are generally easier to clean and maintain after candying due to their non-porous surfaces and resistance to staining. Marble slabs require more careful cleaning to avoid absorbing sugar residues and developing stains over time.

- Metal trays resist staining - Non-porous metal surfaces prevent sugar and syrup absorption, simplifying cleanup.

- Marble slabs absorb residues - Porous marble can trap sugary substances, requiring thorough washing and sealing.

- Durability considerations - Metal trays withstand harsher detergents and scrubbing without damage, unlike more delicate marble.

For ease of cleaning and maintenance in candying, metal trays are typically the preferred choice.

Durability and Longevity: Metal Trays vs Marble Slabs

Metal trays offer superior impact resistance and are less likely to crack or chip during the candying process, ensuring prolonged usability. Marble slabs, while aesthetically pleasing, can suffer from surface wear and potential cracking over time, reducing their lifespan.

- Metal trays resist dents and deformation - High-quality metals such as stainless steel maintain shape under heavy use, enhancing longevity.

- Marble slabs are prone to surface erosion - Continuous exposure to heat and sugar acids gradually deteriorates marble surfaces.

- Metal trays require minimal maintenance - They are easier to clean and less susceptible to damage from repeated temperature changes.

Cost Comparison: Investment Analysis

Metal trays typically offer a lower upfront cost compared to marble slabs, making them a budget-friendly option for candying processes. Marble slabs, although more expensive initially, provide superior heat retention and even cooling, which can enhance candy texture and reduce waste. Evaluating the long-term efficiency and product quality can justify the higher investment in marble for professional confectionery production.

Professional vs Home Use: Which Surface is Preferred?

Which surface is preferred for candying in professional versus home use? Metal trays are favored by professionals for their durability and even heat conduction, essential for consistent candy texture. Home users often prefer marble slabs due to their natural coolness, which helps with rapid sugar cooling and easier handling during candy shaping.

Related Important Terms

Thermal Retention Profile

Metal trays cool rapidly due to high thermal conductivity, causing quicker temperature drops that may lead to uneven candy texture. Marble slabs retain heat longer with slow, consistent cooling, providing superior thermal stability ideal for smooth, glossy candy finishing.

Crystallization Zone Mapping

Metal trays offer rapid heat conduction that accelerates crystallization, whereas marble slabs provide a cooler surface that promotes slower, more controlled crystal formation during candying. Effective crystallization zone mapping reveals that marble slabs create a stable temperature gradient ideal for uniform sugar crystal development, while metal trays can cause uneven cooling and irregular crystal patterns.

Conduction Consistency Index

Metal trays offer superior conduction consistency for candying due to their high thermal conductivity, ensuring even heat distribution and reducing hotspots. In contrast, marble slabs exhibit lower conduction consistency index values, resulting in slower, less uniform temperature regulation that can affect candy texture and quality.

Candy-Pull Temperature Gradient

Metal trays conduct heat rapidly during candy pulling, resulting in a faster temperature gradient that cools the candy quickly and can cause uneven texture. Marble slabs offer a slower, more controlled heat dissipation, maintaining an optimal candy-pull temperature gradient for smoother and more consistent candy texture.

Microcrystal Initiation Point

Metal trays provide a rapid heat conduction surface that promotes uniform microcrystal initiation points during candying, leading to consistent crystallization patterns. Marble slabs, with their slower heat transfer, allow gradual microcrystal nucleation, resulting in larger, more distinct crystal formations on the candy surface.

Surface Energy Differential

Metal trays exhibit higher surface energy compared to marble slabs, promoting quicker water spread and faster crystallization during candying. Marble slabs, with lower surface energy, offer a smoother release of candy, reducing sticking and enabling more uniform sugar coating.

Slab-to-Tray Cooling Lag

Marble slabs offer superior thermal conductivity compared to metal trays, resulting in faster and more uniform cooling during candying processes. The slab-to-tray cooling lag in metal trays can cause uneven crystallization, impacting texture and clarity, whereas marble slabs minimize this lag for optimal candy consistency.

Gloss Finish Yield Rate

Metal trays provide a higher gloss finish yield rate in candying due to their superior heat conductivity and even temperature distribution, which ensures consistent crystallization and clarity. Marble slabs, while offering a natural cooling surface, often result in lower gloss yield because of less uniform heat retention and increased risk of surface moisture affecting the candy's texture.

Candy Flow Drag Coefficient

Metal trays typically exhibit a higher candy flow drag coefficient due to their rougher surface texture, which increases resistance and slows syrup spreading. In contrast, marble slabs possess a smoother, non-porous surface that reduces drag, allowing for more efficient candy flow and uniform coating during the candying process.

Metal Tray vs Marble Slab for Candying. Infographic

cookingdiff.com

cookingdiff.com