Pan candying for pineapple involves slow cooking the fruit in sugar syrup, allowing deep infusion and glossy coating, resulting in a rich, chewy texture; centrifugal candying uses high-speed spinning to remove excess syrup quickly, producing a lighter, less sticky product with uniform sweetness. Pan candying is ideal for smaller batches or artisanal quality, emphasizing flavor absorption and visual appeal, while centrifugal candying suits large-scale production with efficiency and consistent moisture content. Choosing between the two depends on the desired texture, production volume, and final sweetness intensity of the candied pineapple.

Table of Comparison

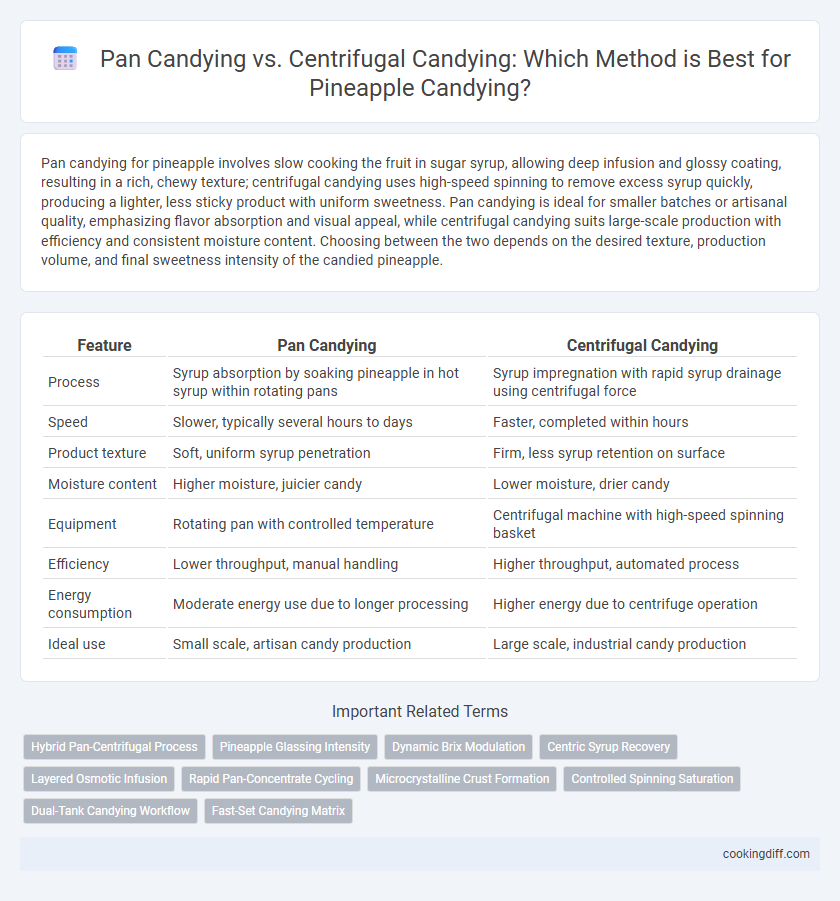

| Feature | Pan Candying | Centrifugal Candying |

|---|---|---|

| Process | Syrup absorption by soaking pineapple in hot syrup within rotating pans | Syrup impregnation with rapid syrup drainage using centrifugal force |

| Speed | Slower, typically several hours to days | Faster, completed within hours |

| Product texture | Soft, uniform syrup penetration | Firm, less syrup retention on surface |

| Moisture content | Higher moisture, juicier candy | Lower moisture, drier candy |

| Equipment | Rotating pan with controlled temperature | Centrifugal machine with high-speed spinning basket |

| Efficiency | Lower throughput, manual handling | Higher throughput, automated process |

| Energy consumption | Moderate energy use due to longer processing | Higher energy due to centrifuge operation |

| Ideal use | Small scale, artisan candy production | Large scale, industrial candy production |

Introduction to Candying Methods in Pineapple Processing

Pan candying and centrifugal candying are two primary methods used in pineapple processing to infuse sugar and preserve the fruit. Pan candying involves simmering pineapple slices in a sugar syrup within large pans, allowing gradual absorption for enhanced flavor and texture. Centrifugal candying uses high-speed spinning to remove excess syrup quickly, resulting in a crisper, less sticky product tailored for mass production and extended shelf life.

Overview: Pan Candying vs Centrifugal Candying

What are the key differences between pan candying and centrifugal candying for pineapple processing? Pan candying involves soaking pineapple slices in syrup within rotating pans, allowing slow absorption for enhanced flavor and chewy texture. Centrifugal candying uses high-speed spinning to remove excess syrup quickly, resulting in a crisper, less dense candy with longer shelf life.

Process Steps: Pan Candying Explained

Pan candying of pineapple involves immersing the fruit slices in a sugar syrup within a large rotating pan, allowing gradual absorption of the syrup. This method focuses on slow drying and frequent stirring to ensure even coating and texture development.

The process steps include blanching the pineapple slices, followed by repeated immersion in increasingly concentrated sugar solutions. Finally, the pan is rotated to evenly distribute the sugar and facilitate drying, resulting in a chewy, glossy candy.

Process Steps: Centrifugal Candying Explained

In centrifugal candying of pineapple, the fruit is first soaked in a concentrated sugar syrup before being placed in a rotating drum to remove excess liquid. The centrifugal force helps evenly distribute the syrup throughout the pineapple pieces, enhancing flavor penetration and texture. This method reduces drying time compared to pan candying, resulting in a firmer, less sticky candied product.

Time Efficiency: Which Method is Faster?

Pan candying generally requires a longer time due to slow syrup absorption and repeated drying cycles. Centrifugal candying speeds up the process by quickly removing excess syrup and moisture, making it more time-efficient for pineapple.

- Pan candying time - Involves multiple heating and cooling stages lasting several hours to days.

- Centrifugal candying speed - Uses centrifugal force to reduce drying time significantly, often completing in hours.

- Efficiency comparison - Centrifugal method offers faster turnaround, ideal for large-scale pineapple candy production.

Quality and Texture Differences

Pan candying preserves the natural moisture of pineapple slices, resulting in a softer, chewier texture, while centrifugal candying removes excess syrup quickly, producing a firmer, more crystalline surface. Quality in pan candying tends to be more uniform with enhanced flavor absorption, whereas centrifugal candying offers a drier finish with extended shelf life.

- Texture difference - Pan candying yields a tender, juicy bite compared to the crisp exterior from centrifugal candying.

- Flavor retention - Pan candying allows deeper syrup penetration, enhancing sweetness and fruitiness.

- Surface quality - Centrifugal candying results in a glossy, less sticky coating due to rapid syrup removal.

Choosing between methods depends on desired pineapple candy texture and storage preferences.

Flavor Retention and Sugar Penetration

Pan candying preserves pineapple's natural flavor more effectively by allowing slower sugar absorption, enhancing taste depth. Centrifugal candying accelerates sugar penetration but may dilute the fruit's intrinsic flavor due to rapid processing.

- Flavor Retention in Pan Candying - Slow diffusion in pan candying ensures pineapple flavor remains robust and distinct.

- Sugar Penetration Rate - Centrifugal candying forces sugar deeper and faster into pineapple cells, altering texture.

- Balance of Sweetness and Taste - Pan candying achieves a harmonious sweetness without compromising pineapple's natural aroma.

Energy Consumption and Cost Comparison

Pan candying of pineapple typically consumes less energy due to lower processing speeds and simpler machinery compared to centrifugal candying. This method requires less initial investment, making it cost-effective for small-scale production.

Centrifugal candying, while more energy-intensive because of high-speed spinning and continuous processing, enhances product uniformity and drying efficiency. Energy consumption in centrifugal candying can be up to 30% higher than pan candying, impacting overall operational costs. However, economies of scale in large-scale operations often offset these costs, making centrifugal candying more viable for mass production.

Scalability for Commercial Pineapple Candying

| Pan Candying | Offers moderate scalability with batch processing suitable for small to medium commercial pineapple candy production; slower syrup absorption impacts throughput. |

| Centrifugal Candying | Enables higher scalability for large-scale commercial pineapple candying through continuous processing and efficient moisture removal, accelerating drying and increasing output capacity. |

Related Important Terms

Hybrid Pan-Centrifugal Process

The hybrid pan-centrifugal candying process combines the thorough syrup absorption of pan candying with the efficient moisture removal of centrifugal candying, optimizing texture and flavor retention in pineapple candy. This method enhances crystal uniformity and reduces processing time, resulting in a superior quality product with improved shelf life compared to traditional single-method techniques.

Pineapple Glassing Intensity

Pan candying achieves a more uniform pineapple glassing intensity by allowing prolonged syrup absorption, enhancing flavor penetration and surface gloss. Centrifugal candying provides a faster drying process but often results in lower glassing intensity and less uniform coverage on pineapple slices.

Dynamic Brix Modulation

Dynamic Brix modulation in pan candying allows precise control over sugar absorption in pineapple slices, enhancing texture and flavor uniformity. In contrast, centrifugal candying rapidly removes excess syrup, enabling higher throughput but requiring careful monitoring to maintain optimal sweetness levels.

Centric Syrup Recovery

Centrifugal candying of pineapple enhances centric syrup recovery by efficiently separating excess syrup from fruit pieces through high-speed spinning, thereby reducing syrup waste and allowing for repeated use in subsequent candying cycles. This method contrasts with pan candying, where syrup retention is higher, leading to increased syrup consumption and lower recovery efficiency.

Layered Osmotic Infusion

Layered osmotic infusion in pineapple candying enhances flavor penetration by alternating syrup concentrations, with pan candying allowing slower, uniform syrup absorption due to constant heat and agitation. In contrast, centrifugal candying accelerates syrup distribution through rapid spinning, promoting efficient moisture removal but potentially reducing the depth of layered infusion.

Rapid Pan-Concentrate Cycling

Pan candying offers precise control over syrup absorption through rapid pan-concentrate cycling, enhancing flavor infusion and texture uniformity in pineapple slices. Centrifugal candying emphasizes efficient syrup removal and drying, resulting in a firmer product but with less control over concentrated flavor penetration.

Microcrystalline Crust Formation

Pan candying promotes the gradual buildup of a uniform microcrystalline crust on pineapple pieces through slow syrup absorption and controlled drying, enhancing texture and shelf stability. Centrifugal candying, by rapidly spinning off excess syrup, results in a thinner microcrystalline layer that reduces surface hardness but may impact the overall crispness and sugar penetration of the pineapple.

Controlled Spinning Saturation

Pan candying allows precise control over spinning saturation, ensuring uniform syrup absorption and optimal texture in pineapple candying. Centrifugal candying uses high-speed spinning to rapidly remove excess syrup, promoting crispness but requiring careful adjustment to prevent under-saturation of pineapple pieces.

Dual-Tank Candying Workflow

Pan candying for pineapple employs a dual-tank system where the fruit is alternately immersed in syrup and dried, enhancing flavor absorption and texture uniformity. Centrifugal candying uses rotation in the second tank to remove excess syrup quickly, optimizing drying time and producing a firmer candy with consistent syrup concentration.

Pan Candying vs Centrifugal Candying for pineapple. Infographic

cookingdiff.com

cookingdiff.com