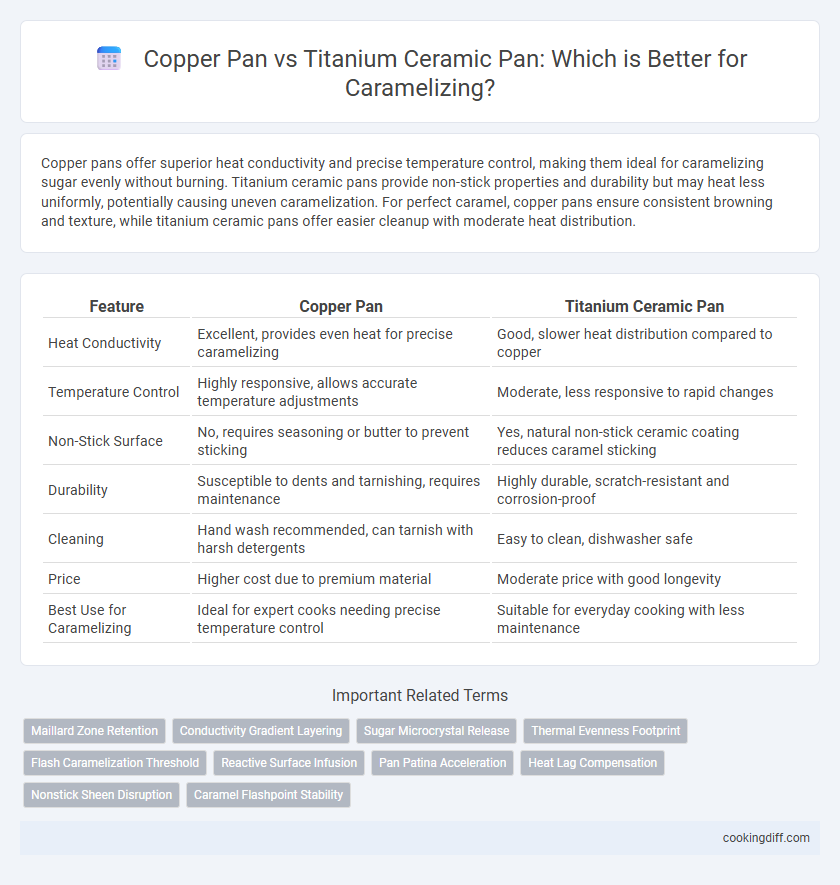

Copper pans offer superior heat conductivity and precise temperature control, making them ideal for caramelizing sugar evenly without burning. Titanium ceramic pans provide non-stick properties and durability but may heat less uniformly, potentially causing uneven caramelization. For perfect caramel, copper pans ensure consistent browning and texture, while titanium ceramic pans offer easier cleanup with moderate heat distribution.

Table of Comparison

| Feature | Copper Pan | Titanium Ceramic Pan |

|---|---|---|

| Heat Conductivity | Excellent, provides even heat for precise caramelizing | Good, slower heat distribution compared to copper |

| Temperature Control | Highly responsive, allows accurate temperature adjustments | Moderate, less responsive to rapid changes |

| Non-Stick Surface | No, requires seasoning or butter to prevent sticking | Yes, natural non-stick ceramic coating reduces caramel sticking |

| Durability | Susceptible to dents and tarnishing, requires maintenance | Highly durable, scratch-resistant and corrosion-proof |

| Cleaning | Hand wash recommended, can tarnish with harsh detergents | Easy to clean, dishwasher safe |

| Price | Higher cost due to premium material | Moderate price with good longevity |

| Best Use for Caramelizing | Ideal for expert cooks needing precise temperature control | Suitable for everyday cooking with less maintenance |

Understanding Caramelization: Why Pan Choice Matters

Caramelization requires precise temperature control to prevent burning and achieve a rich, even color. Choosing the right pan affects heat distribution, crucial for the sugar's Maillard reaction and flavor development.

- Copper pans provide excellent thermal conductivity - They heat quickly and evenly, offering precise temperature control essential for consistent caramelization.

- Titanium ceramic pans retain heat longer - They offer slower heat response which can cause uneven caramelization if not carefully monitored.

- Copper's responsiveness minimizes hot spots - This reduces the risk of sugar burning and ensures smooth, uniform caramel color and flavor.

Copper Pans for Caramelizing: Features and Benefits

Copper pans offer exceptional thermal conductivity, allowing precise temperature control essential for perfect caramelization. Their rapid and even heat distribution prevents hotspots and ensures smooth, consistent caramel results. The responsiveness of copper cookware minimizes the risk of burning sugar, making it ideal for delicate caramelizing tasks.

Titanium Ceramic Pans: Modern Alternative for Caramelizing

Titanium ceramic pans offer a modern alternative to traditional copper pans for caramelizing due to their non-reactive, durable surface that prevents sticking and uneven heating. These pans maintain consistent heat distribution and resist corrosion, allowing for precise caramelization without the risk of metallic flavor transfer.

- Non-reactive surface - Titanium ceramic pans do not react with acidic sugars during caramelizing, preserving flavor integrity.

- Durable and scratch-resistant - Their robust coating withstands high temperatures and frequent use without degrading.

- Even heat distribution - Ensures uniform caramelization by preventing hotspots common with some metal pans.

Titanium ceramic pans present an efficient, low-maintenance option for achieving perfect caramelization results.

Heat Conductivity: Copper vs Titanium Ceramic

Copper pans exhibit superior heat conductivity, enabling rapid and even heat distribution essential for precise caramelizing without hot spots. Titanium ceramic pans have lower thermal conductivity, which may cause uneven heating and require longer cooking times to achieve the desired caramelization. The excellent thermal responsiveness of copper helps prevent burning and ensures consistent color and flavor development in caramelized dishes.

Temperature Control and Precision

Which pan offers better temperature control and precision for caramelizing: copper or titanium ceramic? Copper pans provide superior thermal conductivity, allowing for quick and precise adjustments to temperature essential for perfect caramelization. Titanium ceramic pans heat more slowly and retain heat longer, which can make temperature control less precise but helps maintain consistent heat once the desired temperature is reached.

Nonstick Performance in Caramelizing

| Cuivre Pan | Excellente distribution de la chaleur | Surface naturellement antiadhesive | Caramelisation uniforme grace a la conductivite thermique superieure du cuivre |

| Poele en Ceramique Titane | Chauffe plus lente mais stable | Revetement antiadhesif sans PTFE | Prevention efficace de l'adherence du caramel, nettoyage facile |

Durability and Maintenance: Which Pan Lasts Longer?

Copper pans offer excellent heat conductivity but require regular polishing to prevent tarnishing, impacting long-term durability. Their reactive surface demands careful maintenance to avoid discoloration during caramelizing.

Titanium ceramic pans boast superior scratch resistance and non-reactive properties, making them highly durable with minimal upkeep. These pans maintain their caramelizing performance over time due to their robust coating and easy cleaning features.

Flavor Impact: Does Pan Material Affect Taste?

Copper pans offer superior heat conductivity, allowing for precise temperature control crucial for even caramelization, which enhances the caramel's rich, buttery flavor. Titanium ceramic pans provide a non-reactive surface that prevents metallic taste transfer, maintaining the pure sweetness of caramel.

Copper pans can intensify flavors due to their ability to quickly adjust heat, reducing the risk of burning and bitterness in caramel. Titanium ceramic pans distribute heat evenly but more slowly, which may result in a subtler caramelization process and a milder flavor profile. Choosing copper or titanium ceramic pans ultimately impacts the depth and clarity of caramel flavor based on heat responsiveness and surface reactivity.

Ease of Cleaning After Caramelizing

Copper pans provide excellent heat conductivity for caramelizing but can be challenging to clean due to sugar residues bonding tightly with the metal surface. Their tendency to oxidize requires careful maintenance to prevent tarnishing after each use.

Titanium ceramic pans offer a non-stick surface that significantly simplifies cleaning after caramelizing, preventing caramel from hardening and sticking. These pans resist staining and typically require only gentle washing to restore their smooth finish.

Related Important Terms

Maillard Zone Retention

Copper pans excel in caramelizing due to superior heat conductivity and precise temperature control, allowing consistent maintenance within the Maillard zone (140-165degC) essential for optimal browning. Titanium ceramic pans retain heat unevenly, often causing hotspots or temperature fluctuations that hinder the stable Maillard reaction required for perfect caramelization.

Conductivity Gradient Layering

Copper pans offer superior heat conductivity and precise temperature control essential for even caramelizing, while titanium ceramic pans provide a durable, non-stick surface with a lower conductivity gradient, potentially causing uneven caramelization. The high conductivity gradient layering of copper allows rapid heat adjustments and consistent browning, making it preferable for achieving the perfect caramel texture.

Sugar Microcrystal Release

Copper pans offer superior thermal conductivity, allowing precise temperature control that minimizes sugar microcrystal formation during caramelizing, resulting in a smoother texture. Titanium ceramic pans, while durable and non-reactive, provide less even heat distribution, which can lead to uneven caramelization and increased sugar microcrystal release.

Thermal Evenness Footprint

Copper pans provide exceptional thermal evenness due to their high thermal conductivity, ensuring consistent caramelization without hot spots that can burn sugar. Titanium ceramic pans distribute heat more slowly and unevenly, often resulting in hotspots and an inconsistent caramelizing footprint.

Flash Caramelization Threshold

Copper pans offer superior thermal conductivity, reaching the flash caramelization threshold around 160degC (320degF) quickly and evenly, minimizing the risk of uneven browning or burning. Titanium ceramic pans heat more slowly and less uniformly, often requiring higher temperatures to achieve caramelization, which can result in inconsistent texture and flavor development.

Reactive Surface Infusion

Copper pans offer superior heat conductivity and precise temperature control, crucial for even caramelization without hot spots, while their reactive surface can influence flavor development through subtle chemical interactions. Titanium ceramic pans provide a non-reactive, durable surface that prevents infusion of metallic tastes, ensuring pure caramel flavors but may require more careful temperature management due to slower heat response.

Pan Patina Acceleration

Copper pans accelerate pan patina development during caramelizing due to their superior heat conductivity, enabling precise temperature control and even browning of sugars. Titanium ceramic pans, while durable and non-reactive, tend to slow pan patina formation, resulting in less efficient caramelization performance over time.

Heat Lag Compensation

Copper pans provide superior heat lag compensation due to their excellent thermal conductivity, allowing precise temperature control essential for even caramelization without burning. Titanium ceramic pans, while durable and non-stick, have slower heat response, often causing uneven caramelization and requiring careful heat adjustments to prevent scorching.

Nonstick Sheen Disruption

Copper pans provide excellent heat conductivity for precise caramelizing but may disrupt the nonstick sheen due to their reactive surface. Titanium ceramic pans maintain a more consistent nonstick sheen, preventing sticking and discoloration during the caramelizing process.

Copper pan vs Titanium ceramic pan for caramelizing. Infographic

cookingdiff.com

cookingdiff.com