Caramelizing produces rich, sweet flavors through high-temperature sugar breakdown, creating a deep, intense browning effect. Slow fermentation browning develops complex, nuanced flavors by gradually converting sugars and acids over time, resulting in more subtle, layered taste profiles. Both methods enhance flavor but differ in temperature and time, influencing the final aroma and palate experience.

Table of Comparison

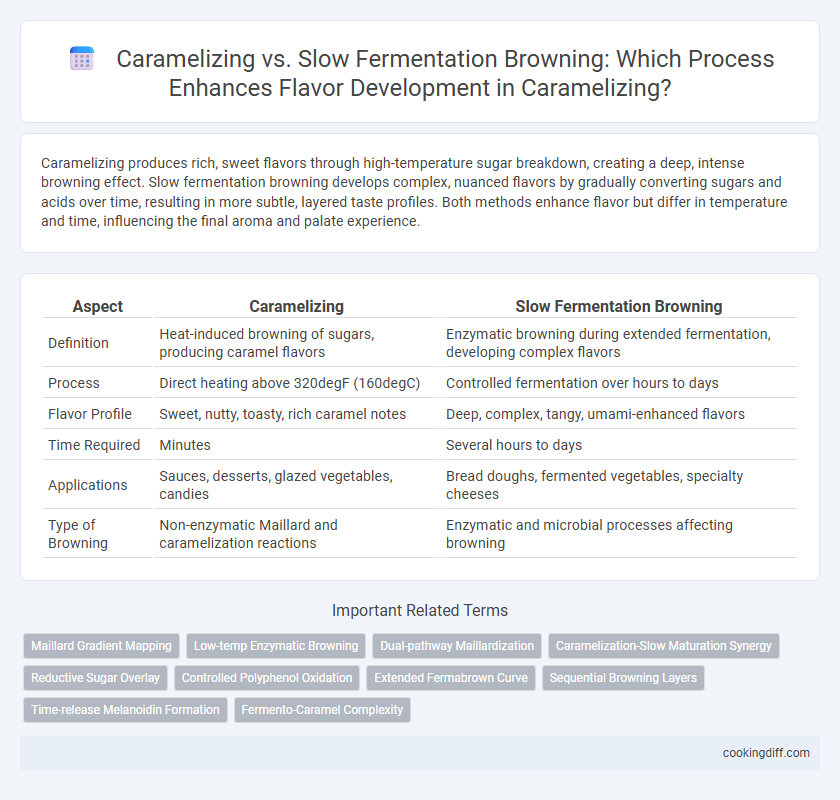

| Aspect | Caramelizing | Slow Fermentation Browning |

|---|---|---|

| Definition | Heat-induced browning of sugars, producing caramel flavors | Enzymatic browning during extended fermentation, developing complex flavors |

| Process | Direct heating above 320degF (160degC) | Controlled fermentation over hours to days |

| Flavor Profile | Sweet, nutty, toasty, rich caramel notes | Deep, complex, tangy, umami-enhanced flavors |

| Time Required | Minutes | Several hours to days |

| Applications | Sauces, desserts, glazed vegetables, candies | Bread doughs, fermented vegetables, specialty cheeses |

| Type of Browning | Non-enzymatic Maillard and caramelization reactions | Enzymatic and microbial processes affecting browning |

Introduction to Flavor Development in Cooking

How do caramelizing and slow fermentation browning differ in enhancing flavor? Caramelizing intensifies sweetness and adds a rich, nutty taste through high heat application, transforming sugars on the food's surface. Slow fermentation browning develops complex, tangy, and umami flavors by enzymatic reactions over time, enhancing depth and aroma in dishes.

What is Caramelizing?

| Caramelizing involves the oxidation of sugar, resulting in a rich, complex flavor and golden-brown color through heat application typically above 320degF (160degC). This chemical process enhances sweetness and produces aromatic compounds that contribute to the depth of flavor in foods like onions and desserts. It differs from slow fermentation browning, which relies on enzymatic reactions developing flavor over time without direct heat. |

The Science Behind Slow Fermentation Browning

Slow fermentation browning involves enzymatic reactions where yeast and bacteria break down sugars, producing complex flavor compounds over time. This process enhances umami and acidity, distinct from the Maillard reaction in caramelizing, which primarily develops sweet and nutty notes through high heat.

The science behind slow fermentation browning centers on controlled sugar metabolism and organic acid production by microorganisms during extended fermentation. Enzymes like invertase and amylase break down starches into fermentable sugars, fueling yeast activity. This gradual enzymatic browning yields deeper flavor profiles and improved dough texture compared to the rapid non-enzymatic caramelizing process.

Key Chemical Reactions: Maillard vs. Caramelization

Caramelizing involves the thermal decomposition of sugars producing rich, sweet, and nutty flavors, whereas slow fermentation browning primarily triggers Maillard reactions between amino acids and reducing sugars, enhancing complex savory aromas. Both chemical pathways significantly contribute to flavor development but differ fundamentally in substrates and reaction mechanisms.

- Caramelization - Sugar molecules break down under heat typically above 160degC, creating caramel flavors and brown pigments called melanoidins.

- Maillard Reaction - Amino acids react with reducing sugars at lower temperatures (140-165degC), generating a diverse array of flavor compounds and browning in fermented foods.

- Flavor Profile Impact - Caramelization imparts sweet, buttery notes while Maillard reactions yield deeper, savory, roasted flavors essential in slow-fermented products.

Time and Temperature: Critical Factors Compared

Caramelizing relies on high temperatures typically between 320degF and 350degF to rapidly develop intense sweetness and complex flavors within minutes. Slow fermentation browning occurs over hours to days at much lower temperatures, enhancing flavor through enzymatic and microbial activity rather than direct heat application.

- Caramelizing involves high heat - It uses elevated temperatures to quickly trigger Maillard reactions and sugar breakdown.

- Slow fermentation relies on time - Extended periods allow gradual development of organic acids and aromatic compounds.

- Temperature controls flavor profile - Higher heat intensifies caramel notes while cooler conditions yield nuanced, tangy flavors.

Flavor Profiles: Caramelizing vs. Slow Fermentation

Caramelizing develops complex, sweet, and nutty flavors through the Maillard reaction at high heat, enhancing the depth of food's natural sugars. Slow fermentation browning creates tangy, savory, and mildly acidic notes by allowing enzymatic reactions to evolve over time.

These distinct flavor profiles influence culinary applications: caramelizing suits dishes needing rich, crisp textures, while slow fermentation imparts nuanced umami and subtle sourness, ideal for artisan breads and fermented products.

Best Ingredients for Each Browning Technique

Caramelizing best suits ingredients high in natural sugars like onions, carrots, and bell peppers, as intense heat enhances their sweetness and produces a rich, complex flavor profile. Slow fermentation browning is ideal for ingredients rich in complex carbohydrates and proteins, such as doughs or fermented vegetables, where enzymatic reactions gradually develop deeper umami and tangy notes. Selecting the right ingredients based on sugar content or fermentable substrates ensures optimal flavor development for each browning technique.

Practical Applications in Home and Professional Kitchens

Caramelizing enhances flavor by applying direct heat to sugars, creating deep, rich notes ideal for quick flavor development in both home and professional kitchens. Slow fermentation browning relies on enzymatic and Maillard reactions over time, producing complex, nuanced flavors suited for breads and aged foods.

- Caramelizing - Involves high-temperature cooking that rapidly browns sugars, perfect for sauces, vegetables, and desserts.

- Slow Fermentation Browning - Utilizes yeast or bacteria activity over hours or days to generate natural sweetness and a golden crust in baked goods.

- Flavor Complexity - Slow fermentation develops layered tastes while caramelizing delivers intense, immediate caramel notes preferred in savory and sweet dishes.

Choosing between these techniques depends on desired flavor depth and available preparation time in kitchen settings.

Health and Nutritional Implications

Caramelizing enhances flavor through the Maillard reaction, generating complex compounds that may increase acrylamide levels, a potential health concern linked to carcinogenic effects. Slow fermentation browning produces fewer harmful byproducts and can improve gut health by promoting beneficial probiotics.

While caramelization yields rich, sweet flavors, it may reduce nutritional value by degrading some vitamins. Slow fermentation preserves more nutrients and supports digestion, making it a healthier option for flavor development in foods.

Related Important Terms

Maillard Gradient Mapping

Caramelizing involves the thermal decomposition of sugars, creating rich, sweet, and nutty flavors through pyrolysis, while slow fermentation browning develops complex umami and roasted notes via controlled Maillard reactions over extended time. Maillard Gradient Mapping reveals distinct flavor development zones, showing caramelization peaks at higher temperatures and slow fermentation browning intensifying flavor complexity through prolonged amino acid-sugar interactions.

Low-temp Enzymatic Browning

Caramelizing involves high-temperature sugar oxidation producing rich, complex flavors, while slow fermentation browning leverages low-temp enzymatic processes that gently develop nuanced, sweeter notes through the action of polyphenol oxidase on phenolic compounds. Low-temp enzymatic browning allows controlled flavor enhancement by preserving delicate aromatics and generating natural pigments, contrasting with the intense caramelized profiles formed by thermal degradation.

Dual-pathway Maillardization

Caramelizing involves the thermal decomposition of sugars at high temperatures, producing rich, sweet, and nutty flavors through sugar polymerization, while slow fermentation browning relies on enzymatic reactions and prolonged Maillard reactions between amino acids and reducing sugars, enhancing complex umami and roasted notes. Dual-pathway Maillardization integrates both heat-induced caramelization and enzymatic fermentation processes, maximizing flavor development by combining the depth of caramelized sugars with the savory compounds generated during slow browning.

Caramelization-Slow Maturation Synergy

Caramelization intensifies flavor by driving Maillard reactions at high heat, producing complex aromatic compounds, while slow fermentation browning develops subtle sweetness and depth over time through enzymatic activity. The synergy between caramelization and slow maturation enhances flavor complexity by blending immediate thermal browning with prolonged biochemical transformations for a richer, more nuanced taste profile.

Reductive Sugar Overlay

Caramelizing enhances flavor development through the Maillard reaction, where reductive sugar overlay interacts with amino acids to produce complex, rich browning compounds. Slow fermentation browning relies on enzymatic breakdown of sugars over time, allowing gradual buildup of reductive sugars that intensify flavor depth and nuanced sweetness.

Controlled Polyphenol Oxidation

Caramelizing develops flavor through the controlled thermal breakdown of sugars, generating rich, complex caramel notes, while slow fermentation browning enhances taste primarily via controlled polyphenol oxidation, which intensifies aroma and depth by transforming phenolic compounds. Both processes rely on precise temperature and timing control to optimize flavor profiles, with polyphenol oxidation playing a critical role in achieving desired sensory characteristics in slow-fermented products.

Extended Fermabrown Curve

The Extended Fermabrown Curve captures the nuanced differences between caramelizing and slow fermentation browning, highlighting how controlled enzymatic reactions during slow fermentation produce complex flavor compounds over time. Caramelizing rapidly induces Maillard reactions and sugar breakdown, creating intense, sweet, and toasted notes, whereas slow fermentation develops deeper, layered flavors through prolonged biochemical changes.

Sequential Browning Layers

Caramelizing creates complex sequential browning layers by rapidly heating sugars, resulting in intensified flavor profiles with rich, nutty, and sweet notes. Slow fermentation browning develops these layers over time through enzymatic reactions, producing subtle, nuanced flavors with enhanced depth and aromatic complexity.

Time-release Melanoidin Formation

Caramelizing involves rapid browning through high heat, producing intense, immediate flavors, whereas slow fermentation browning promotes gradual, time-release melanoidin formation, resulting in deeper, complex flavor profiles. The extended duration of slow fermentation enhances Maillard reactions and melanoidin development, improving flavor stability and richness over time.

Caramelizing vs Slow Fermentation Browning for flavor development. Infographic

cookingdiff.com

cookingdiff.com