Metal pans provide even heat distribution and durability, making them suitable for caramelizing sugar without hot spots that cause burning. Copper pans excel in precise temperature control, allowing for smoother caramelization due to their superior heat conductivity. Choosing between these pans depends on whether even heat or precise temperature management is the priority for perfect caramelizing results.

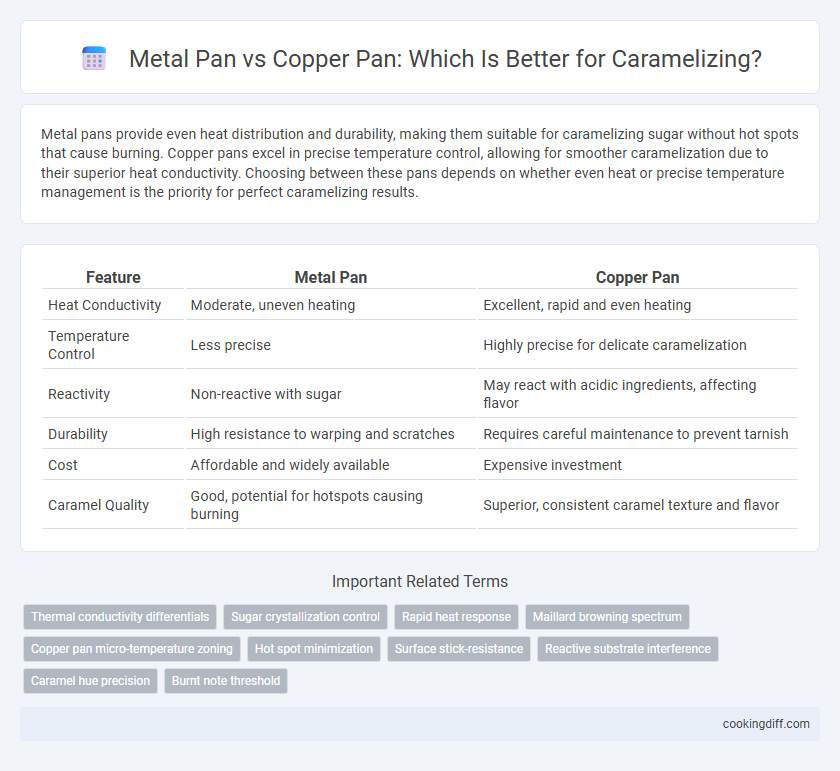

Table of Comparison

| Feature | Metal Pan | Copper Pan |

|---|---|---|

| Heat Conductivity | Moderate, uneven heating | Excellent, rapid and even heating |

| Temperature Control | Less precise | Highly precise for delicate caramelization |

| Reactivity | Non-reactive with sugar | May react with acidic ingredients, affecting flavor |

| Durability | High resistance to warping and scratches | Requires careful maintenance to prevent tarnish |

| Cost | Affordable and widely available | Expensive investment |

| Caramel Quality | Good, potential for hotspots causing burning | Superior, consistent caramel texture and flavor |

Introduction to Caramelizing: Why Pan Material Matters

Caramelizing requires precise temperature control to achieve perfect browning without burning. Metal pans, such as stainless steel, offer durability and even heat distribution but may develop hot spots that affect caramelization.

Copper pans provide superior thermal conductivity, allowing faster and more responsive temperature adjustments during caramelizing. This helps prevent scorching and promotes consistent caramel color and flavor development.

Metal Pan Basics: Types and Properties

Metal pans used for caramelizing typically include stainless steel, cast iron, and aluminum, each offering distinct heat conduction and retention properties. Stainless steel pans provide even heating but may develop hot spots, while cast iron pans retain heat longer, promoting consistent caramelization. Copper pans excel in precise temperature control due to superior thermal conductivity, reducing the risk of burning sugar during caramelizing.

Copper Pan Overview: Advantages in the Kitchen

| Material | Heat Conductivity | Temperature Control | Caramelization Results |

|---|---|---|---|

| Copper Pan | Exceptional thermal conductivity ensures even heating without hot spots | Precise temperature regulation allows for perfect caramelization without burning | Consistent browning and smooth texture yield superior caramel flavor |

| Metal Pan (e.g., Stainless Steel) | Moderate conductivity may cause uneven heating and hotspots | Less responsive to temperature changes, increasing risk of scorching | Uneven caramelization with potential for bitter or burnt notes |

Heat Conductivity: Metal Pan vs Copper Pan

Metal pans offer decent heat conductivity but often result in uneven heating during caramelizing, which can cause hot spots and inconsistent caramel formation. Copper pans excel in heat conductivity, providing rapid and uniform heat distribution that is ideal for precise caramelization.

Copper pans respond quickly to temperature changes, allowing better control over the delicate caramelization process, essential for achieving the perfect texture and flavor. Metal pans, such as stainless steel or cast iron, tend to retain heat longer but may not heat as evenly, increasing the risk of burning or crystallization. The superior heat conductivity of copper ensures smooth, consistent caramel with reduced risk of scorching compared to standard metal pans.

Temperature Control: Achieving Perfect Caramelization

Metal pans, such as stainless steel, offer consistent heat distribution but can retain high temperatures longer, making temperature control during caramelization more challenging. Copper pans provide superior thermal conductivity, allowing for rapid adjustments and precise temperature management essential for achieving perfect caramelization.

The ability of copper pans to quickly respond to temperature changes minimizes the risk of burning sugar, resulting in an even, golden caramel. In contrast, metal pans require more attention to prevent overheating due to slower heat dissipation.

Reaction Time: Speed Differences in Caramelizing

Copper pans heat up and cool down rapidly, allowing for precise control during caramelization, which shortens reaction time and reduces burning risk. Metal pans, typically made of stainless steel or cast iron, heat more slowly and maintain temperature longer, resulting in a steadier but slower caramelization process.

- Copper pans - Offer superior thermal conductivity, enabling quicker reaction times when caramelizing sugars.

- Metal pans - Hold heat longer, causing a more gradual caramelization and less chance of sudden temperature spikes.

- Speed differences - Copper pans caramelize sugars faster due to rapid temperature changes compared to conventional metal pans.

Choosing between copper and metal pans depends on the desired control and speed during the caramelizing process.

Flavor Impact: Does Pan Material Affect Taste?

Caramelizing in a copper pan often results in a more even heat distribution, which can enhance the depth of flavor due to precise temperature control. Metal pans, such as stainless steel, may cause uneven heating, potentially leading to inconsistent caramelization and slight bitter notes.

- Copper's Superior Heat Conductivity - Copper pans provide consistent heat, reducing hotspots that can burn sugar and affect flavor negatively.

- Metal Pan Variability - Stainless steel and other metals heat unevenly, which may cause partial burning and off-flavors in caramelized dishes.

- Flavor Nuance - The controlled caramelization in copper pans produces a smoother, richer flavor profile compared to some metal pans.

Maintenance and Durability: Cleaning and Care Tips

Metal pans, especially stainless steel, offer high durability and resist corrosion, making them easier to maintain after caramelizing. Copper pans require careful cleaning to prevent tarnishing and usually need polishing to retain their appearance, as acidic caramel can damage the metal over time. Proper drying and avoiding abrasive cleaners extend the lifespan of both pans, but copper demands more attentive care for long-term use.

Cost Comparison: Investing in the Right Pan

Which pan offers the best value for caramelizing: metal or copper? Metal pans are generally more affordable, making them a practical choice for home cooks on a budget. Copper pans, while significantly more expensive, provide superior heat conductivity and precision, ideal for professional chefs seeking optimal caramelization results.

Related Important Terms

Thermal conductivity differentials

Copper pans excel in caramelizing due to their superior thermal conductivity, which provides rapid and even heat distribution, preventing hot spots and burning. Metal pans, such as stainless steel, have lower thermal conductivity, resulting in slower heat transfer and less precise temperature control during the caramelization process.

Sugar crystallization control

Copper pans offer superior heat conductivity and precise temperature control, essential for preventing sugar crystallization during caramelizing. Metal pans, especially stainless steel, heat unevenly, increasing the risk of hot spots that cause premature sugar crystallization and grainy caramel texture.

Rapid heat response

Copper pans provide rapid heat response during caramelizing, allowing precise temperature control and reducing the risk of burning sugar. Metal pans, while durable, often heat less evenly and respond slower to temperature changes, which can lead to uneven caramelization.

Maillard browning spectrum

Copper pans provide superior temperature control and rapid heat conduction, promoting consistent Maillard browning and reducing the risk of burning during caramelization compared to metal pans. In contrast, metal pans, such as stainless steel, heat less evenly, often causing uneven caramelization and a narrower Maillard browning spectrum.

Copper pan micro-temperature zoning

Copper pans provide superior caramelizing results due to their excellent micro-temperature zoning, allowing precise control over heat distribution and preventing hotspot formation. This ensures even caramelization and prevents burning, unlike metal pans that often have uneven heat conduction leading to inconsistent caramelization.

Hot spot minimization

Copper pans offer superior heat conductivity and distribution, minimizing hot spots during caramelizing for more even cooking compared to metal pans. Metal pans, such as stainless steel, often develop uneven temperature zones that can cause irregular caramelization and scorching.

Surface stick-resistance

Copper pans offer superior heat conductivity, allowing for precise temperature control that reduces burning and sticking when caramelizing. Metal pans, especially stainless steel, often have a less non-stick surface, increasing the risk of caramel adhering and requiring more careful stirring to prevent burning.

Reactive substrate interference

Metal pans such as stainless steel or aluminum can react with acidic ingredients during caramelizing, leading to off-flavors and discoloration in the caramel, while copper pans offer superior heat conductivity and a non-reactive surface that prevents chemical interference. The non-reactive nature of copper ensures consistent caramelization without altering the taste or color, making it the preferred choice for precise temperature control and purity in flavor development.

Caramel hue precision

Copper pans provide superior heat conductivity and precise temperature control, enabling optimal caramel hue development during caramelizing. Metal pans, especially stainless steel, offer less temperature responsiveness, often resulting in inconsistent caramel color and risk of scorching.

Metal pan vs copper pan for caramelizing. Infographic

cookingdiff.com

cookingdiff.com