Traditional ladles provide controlled pouring for caramelizing with steady heat application, but require skill to avoid overheating or uneven caramelization. Thermal caramelizing wands offer precise temperature control and direct heat application, enabling consistent caramel texture and reducing the risk of burning. Using a thermal wand enhances efficiency and results in a smoother, more uniform caramel finish compared to traditional ladles.

Table of Comparison

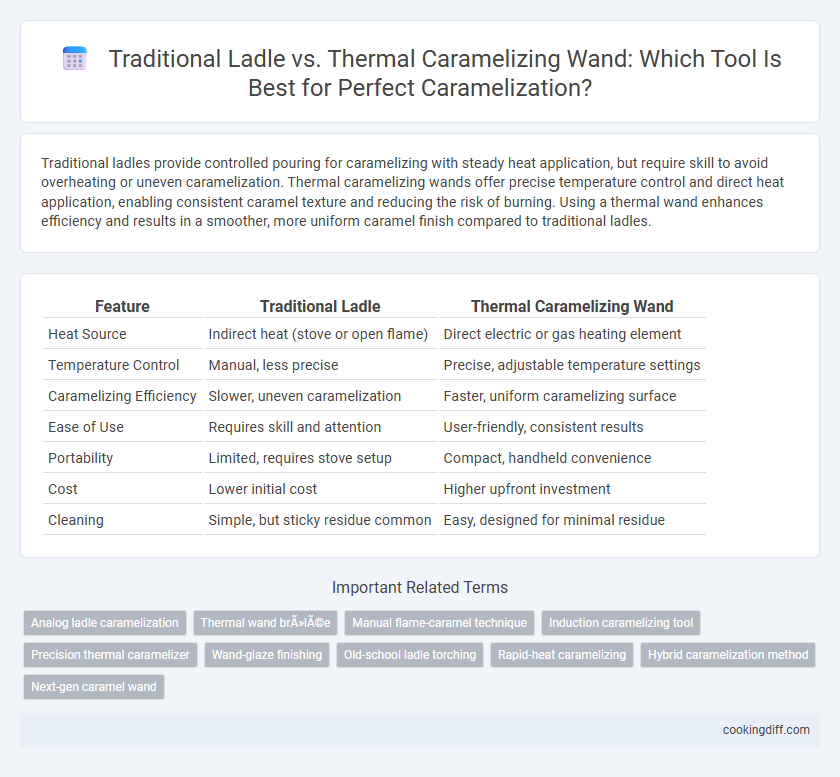

| Feature | Traditional Ladle | Thermal Caramelizing Wand |

|---|---|---|

| Heat Source | Indirect heat (stove or open flame) | Direct electric or gas heating element |

| Temperature Control | Manual, less precise | Precise, adjustable temperature settings |

| Caramelizing Efficiency | Slower, uneven caramelization | Faster, uniform caramelizing surface |

| Ease of Use | Requires skill and attention | User-friendly, consistent results |

| Portability | Limited, requires stove setup | Compact, handheld convenience |

| Cost | Lower initial cost | Higher upfront investment |

| Cleaning | Simple, but sticky residue common | Easy, designed for minimal residue |

Introduction to Caramelizing Techniques

What are the differences between traditional ladle and thermal caramelizing wand in caramelizing? Traditional ladles require precise timing and constant attention to achieve the perfect caramelization, often needing skilled hands to avoid burning. Thermal caramelizing wands provide consistent, controlled heat, allowing for more uniform caramelization and easier handling in professional kitchens.

What is a Traditional Ladle in Caramelizing?

A traditional ladle used in caramelizing is a simple, heat-resistant metal tool designed to pour hot sugar mixtures with precision. Its basic construction allows for controlled caramel flow and easy handling during the cooking process.

- Material - Typically made from stainless steel or aluminum to withstand high temperatures without warping.

- Design - Features a deep bowl and long handle to safely hold and pour molten caramel.

- Usage - Allows cooks to scoop, transfer, and drizzle caramel directly onto desserts or molds.

The Rise of the Thermal Caramelizing Wand

The rise of the thermal caramelizing wand revolutionizes caramelizing by offering precise temperature control and even heat distribution, unlike the traditional ladle which relies on manual stirring and inconsistent heat. This modern tool reduces caramel burn risks and enhances flavor consistency, making it a favorite among professional chefs and home cooks alike. Thermal caramelizing wands are increasingly adopted for their efficiency, safety, and ability to produce perfectly caramelized dishes every time.

How Each Tool Works: Ladle vs Wand

The traditional ladle caramelizes sugar by heating the caramel over an open flame and then carefully pouring it onto the dish. In contrast, the thermal caramelizing wand uses an electric heating element to directly apply precise heat, allowing for controlled caramelization without additional cooking vessels.

- Traditional ladle heats sugar - It requires manual control of flame intensity and timing to avoid burning.

- Thermal caramelizing wand offers precision - The built-in thermostat maintains consistent temperature for even caramelization.

- Ladle needs more skill - Caramelization depends heavily on the user's experience and technique.

The thermal caramelizing wand provides a safer, more consistent method compared to the skill-dependent ladle approach.

Comparing Heat Control and Precision

| Method | Heat Control | Precision |

|---|---|---|

| Traditional Ladle | Relies on manual adjustment over an open flame, offering limited and uneven heat distribution. | Precision depends on user skill, making consistent caramelization challenging. |

| Thermal Caramelizing Wand | Features adjustable temperature settings for precise and consistent heat application. | Allows exact control over caramel color and texture, improving repeatability and quality. |

Efficiency and Speed: Which Tool Wins?

The traditional ladle offers control but often requires longer heating times, reducing overall caramelizing efficiency. In contrast, the thermal caramelizing wand leverages precise temperature regulation for faster, more consistent caramel formation.

Speed tests reveal that the thermal caramelizing wand can cut caramelizing time by up to 40%, enhancing productivity in professional kitchens. Its design ensures even heat distribution, minimizing the risk of burning compared to the traditional ladle.

Flavor Outcomes: Traditional vs Modern Methods

The traditional ladle method enhances caramel's rich, deep flavors through slow, controlled heating, allowing sugar to develop complex, nuanced notes. In contrast, the thermal caramelizing wand uses precise temperature control to achieve consistent caramelization with a cleaner, slightly lighter taste profile.

The ladle's direct heat imparts a robust, smoky character often preferred in artisanal cooking, while the thermal wand minimizes the risk of burning, preserving caramel's natural sweetness. Chefs using the wand benefit from repeatable results that maintain flavor balance and clarity. Both tools shape caramel's taste but cater to differing culinary preferences and techniques.

Safety Considerations: Ladle vs Wand

Traditional ladles used for caramelizing require careful handling due to the risk of hot caramel splattering, which can cause burns. Their metal construction can become extremely hot, necessitating the use of heat-resistant gloves for safety during use.

Thermal caramelizing wands offer improved safety by providing better temperature control and reducing direct contact with hot caramel. These wands often feature insulated handles and precise heat settings, minimizing the risk of burns and enhancing operator protection.

Maintenance and Durability Comparison

Traditional ladles require frequent cleaning and careful handling to avoid damage, while thermal caramelizing wands offer easier maintenance with detachable parts and simple cleaning protocols. The durability of thermal wands generally surpasses that of ladles due to heat-resistant materials and sturdier construction designed for prolonged use.

- Maintenance simplicity - Thermal caramelizing wands feature detachable components that facilitate thorough cleaning and reduce downtime.

- Material resilience - Thermal wands use heat-resistant alloys that withstand repeated heating cycles better than typical ladle metals.

- Longevity - The robust design of thermal wands results in longer service life compared to traditional ladles prone to warping or corrosion.

Related Important Terms

Analog ladle caramelization

Analog ladle caramelization provides precise control over heat application, allowing for even browning and rich flavor development in caramel. Unlike thermal caramelizing wands, the traditional ladle enables gradual temperature adjustments, enhancing the texture and depth of the caramel through manual stirring and monitoring.

Thermal wand brûlée

Thermal caramelizing wands deliver precise, even heat for perfectly bruleed sugar with minimal risk of burning, unlike traditional ladles that rely on manual control and open flame, which can cause uneven caramelization. The thermal wand's advanced temperature regulation ensures a consistent golden crust, enhancing texture and flavor in desserts such as creme brulee.

Manual flame-caramel technique

Traditional ladle caramelizing relies on direct manual flame exposure to melt and brown sugars, offering precise control over texture but requiring skill to avoid burning. Thermal caramelizing wands provide consistent, even heat distribution with adjustable temperatures, reducing the risk of overcaramelization while maintaining the authentic flavor profile of flame-caramelized dishes.

Induction caramelizing tool

Induction caramelizing tools, such as thermal caramelizing wands, offer precise temperature control and faster heat-up times compared to traditional ladles, enhancing caramelization consistency and reducing the risk of burning. Their compatibility with induction cooktops ensures efficient energy use and even heat distribution, which is critical for achieving the perfect caramel crust in professional kitchens.

Precision thermal caramelizer

The precision thermal caramelizer offers superior temperature control for consistent caramelization compared to traditional ladles, which often cause uneven heating and burning due to manual methods. Its advanced thermal technology ensures precise caramel browning, enhancing flavor quality and reducing waste in culinary applications.

Wand-glaze finishing

The thermal caramelizing wand offers precise temperature control and consistent heat distribution, resulting in an even, glossy caramel glaze finish that enhances texture and flavor. Unlike traditional ladles, the wand minimizes the risk of burning or crystallization, ensuring a smooth, professional-quality caramel coating.

Old-school ladle torching

Traditional ladle torching for caramelizing relies on a handheld metal ladle filled with sugar, heated over an open flame to achieve a rich, amber crust, offering precise control and a classic, artisanal finish. Unlike thermal caramelizing wands, the ladle provides direct, intense heat that enables chefs to caramelize small batches efficiently while maintaining the authentic texture and flavor of crusted desserts like creme brulee.

Rapid-heat caramelizing

Traditional ladles provide gradual heat transfer for caramelizing, requiring longer exposure to high temperatures and increasing the risk of uneven browning. Thermal caramelizing wands deliver rapid, precise heat directly to the sugar surface, enabling faster caramelization with consistent, controlled results ideal for professional culinary applications.

Hybrid caramelization method

The hybrid caramelization method combines the traditional ladle's precise control with the thermal caramelizing wand's rapid, even heat distribution, maximizing flavor development and texture consistency. This approach optimizes sugar melting and browning by leveraging the ladle's artisanal touch alongside the wand's advanced thermal efficiency.

Traditional ladle vs thermal caramelizing wand for caramelizing. Infographic

cookingdiff.com

cookingdiff.com