A basic sugar thermometer provides precise internal temperature readings essential for perfect caramelization, ensuring sugar reaches exact stages like soft ball or hard crack. Infrared thermometers measure surface temperature without contact but may give inconsistent readings due to the sugar's uneven surface and crystallization. For consistent caramel results, a basic sugar thermometer is more reliable than an infrared thermometer.

Table of Comparison

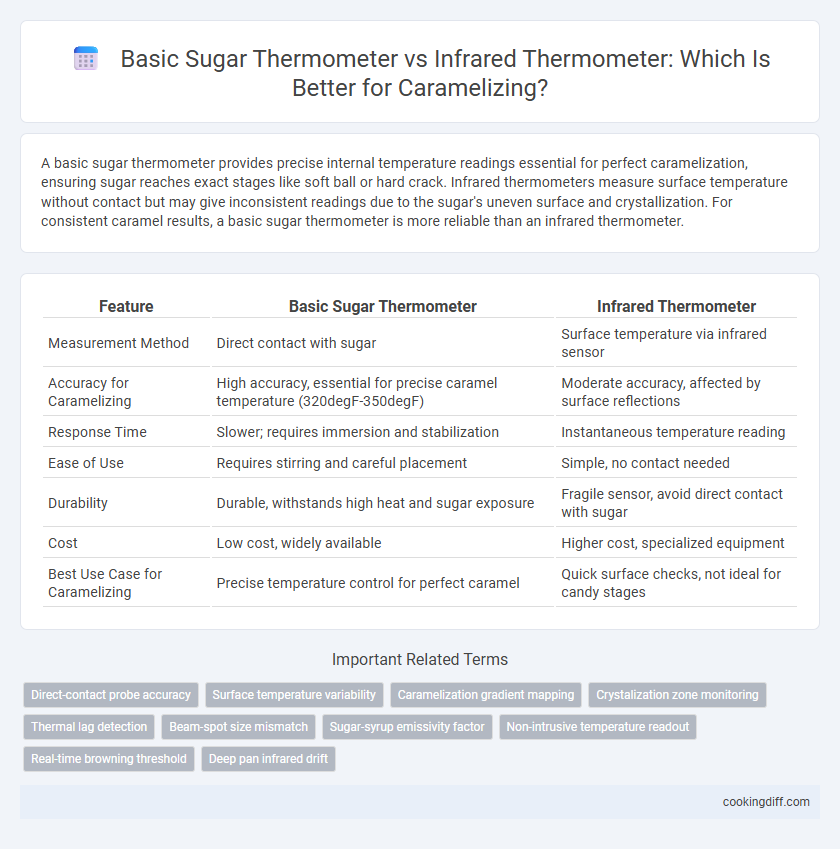

| Feature | Basic Sugar Thermometer | Infrared Thermometer |

|---|---|---|

| Measurement Method | Direct contact with sugar | Surface temperature via infrared sensor |

| Accuracy for Caramelizing | High accuracy, essential for precise caramel temperature (320degF-350degF) | Moderate accuracy, affected by surface reflections |

| Response Time | Slower; requires immersion and stabilization | Instantaneous temperature reading |

| Ease of Use | Requires stirring and careful placement | Simple, no contact needed |

| Durability | Durable, withstands high heat and sugar exposure | Fragile sensor, avoid direct contact with sugar |

| Cost | Low cost, widely available | Higher cost, specialized equipment |

| Best Use Case for Caramelizing | Precise temperature control for perfect caramel | Quick surface checks, not ideal for candy stages |

Understanding Caramelization: The Role of Temperature

Understanding caramelization requires precise temperature control, with basic sugar thermometers providing direct contact measurements that ensure accurate monitoring of sugar's critical temperature range between 320degF and 350degF. Infrared thermometers offer quick, non-contact readings ideal for surface temperature detection but may be less precise in reflecting the true internal temperature of melting sugar. Choosing the right thermometer impacts the consistency of caramelization by preventing burning or undercooking, essential for achieving perfect caramel texture and flavor.

Sugar Thermometer Basics: Traditional Tools for Precision

Sugar thermometers, typically glass or digital probe types, provide direct temperature readings essential for precise caramelizing. These tools measure the sugar's actual temperature, ensuring accurate control over stages like soft ball, hard crack, and caramelization points.

Infrared thermometers offer non-contact temperature measurements but only gauge surface temperature, which can mislead during caramelizing due to sugar's uneven heating. Relying on traditional sugar thermometers guarantees more reliable results for critical temperature-sensitive sugar work.

Infrared Thermometer Overview: Modern Approach to Heat Measurement

Infrared thermometers provide a modern approach to heat measurement by detecting surface temperature without direct contact, making them ideal for precise caramelizing. Unlike basic sugar thermometers, they offer quick readings and reduce the risk of contamination or sugar crystal interference.

Infrared thermometers utilize infrared sensors to measure the emitted radiation from the sugar's surface, ensuring accurate and instantaneous temperature data. This technology allows for better temperature control during caramelization, preventing burning or undercooking. Their easy-to-use digital interface and non-invasive nature make them preferred tools in both professional and home kitchens.

Accuracy in Caramelizing: Comparing Sugar and Infrared Thermometers

Sugar thermometers provide precise temperature readings essential for caramelizing sugar at specific stages like soft ball, hard ball, and caramel. Their accuracy within 1-2degF ensures consistent caramelization results and prevents burning.

Infrared thermometers measure surface temperature quickly but may give less reliable readings due to sugar's reflective properties and uneven heating. For optimal caramel control, sugar thermometers remain the preferred tool among professional chefs and confectioners.

Response Time: Speed of Temperature Readings

Basic sugar thermometers have a slower response time, requiring immersion in the sugar mixture to register accurate readings. Infrared thermometers provide near-instant temperature readings without contact, ideal for quick adjustments during caramelizing.

- Basic sugar thermometer response time - Typically takes 30 seconds to a minute to stabilize in hot sugar mixtures, slowing down the caramelizing process.

- Infrared thermometer speed - Measures surface temperature in less than a second, allowing rapid monitoring of caramel temperature.

- Impact on caramelizing - Faster readings help prevent burning by enabling immediate corrections to heat levels.

Ease of Use: Handling and Safety Considerations

Basic sugar thermometers require direct contact with the caramel, making them slightly more challenging to handle due to the risk of burns and the need for careful insertion. Infrared thermometers offer a non-contact method, enhancing safety and ease of use during caramelization by allowing quick temperature readings from a distance.

- Basic sugar thermometer handling - Requires immersion into hot sugar, increasing the chance of burns and splashes.

- Infrared thermometer handling - Measures surface temperature without contact, minimizing risk and simplifying use.

- Safety considerations - Infrared thermometers reduce exposure to hot sugar and open flames, improving user safety.

Choosing an infrared thermometer improves ease of use and safety when caramelizing sugar.

Cleaning and Maintenance: Keeping Your Thermometers Ready

Cleaning and maintaining basic sugar thermometers involves carefully wiping the probe to avoid water damage and ensuring no sugar residue hardens, which can affect accuracy. Infrared thermometers require less direct contact cleaning but need regular lens cleaning to maintain precise temperature readings.

- Basic sugar thermometer cleaning - Gently clean the probe with warm soapy water and avoid submerging electrical parts to prevent damage.

- Infrared thermometer maintenance - Use a soft, dry cloth to clean the lens regularly and avoid abrasive materials that could scratch the sensor.

- Storage considerations - Store both thermometers in a dry, cool environment to prevent moisture buildup and prolong sensor lifespan.

Versatility in the Kitchen: Multi-Use Benefits

Basic sugar thermometers provide precise temperature readings crucial for perfect caramelizing, ensuring sugar reaches the exact soft ball or hard crack stage. Infrared thermometers offer versatility by allowing quick surface temperature checks on pans, syrups, and other cooking elements without direct contact. Both tools enhance kitchen efficiency, with sugar thermometers specialized for candy making and infrared models ideal for diverse culinary uses beyond caramelizing.

Price Point: Cost Comparison and Value

| Thermometer Type | Average Cost | Value for Caramelizing |

|---|---|---|

| Basic Sugar Thermometer | $10 - $25 | Affordable and specifically designed for high temperatures, providing accurate readings essential for precise caramelization. |

| Infrared Thermometer | $30 - $100+ | Higher price point but offers quick non-contact measurements; may lack the precise temperature range calibration required for caramelizing sugar effectively. |

Related Important Terms

Direct-contact probe accuracy

A basic sugar thermometer with a direct-contact probe provides precise and consistent temperature readings crucial for caramelizing sugar, allowing accurate monitoring of the critical stages from soft ball to hard crack. Infrared thermometers, while convenient for non-contact measurements, often yield less reliable readings on shiny caramel surfaces due to emissivity variations, making direct-contact probes preferable for precise caramelization control.

Surface temperature variability

A basic sugar thermometer measures the temperature of the sugar mixture by direct contact, providing precise readings crucial for accurate caramelization stages, while an infrared thermometer reads surface temperature variability non-invasively, which can be less consistent due to uneven heat distribution and reflective surfaces. Choosing between them depends on whether accurate internal sugar temperature or quick surface assessments are prioritized during the caramelizing process.

Caramelization gradient mapping

Basic sugar thermometers provide direct contact temperature readings essential for precise caramelization stages, ensuring accurate heat control for consistent sugar gradients. Infrared thermometers enable non-contact surface temperature mapping, facilitating quick gradient analysis but may lack depth accuracy critical for uniform caramelization.

Crystalization zone monitoring

A basic sugar thermometer provides precise temperature readings directly within the caramelization mixture, ensuring accurate monitoring of the critical crystallization zone between 230degF and 245degF. Infrared thermometers, while non-contact and quick, often fail to measure internal temperatures accurately, risking undetected crystal formation and inconsistent caramel texture.

Thermal lag detection

A basic sugar thermometer measures temperature directly by being immersed in the caramel, providing accurate readings with minimal thermal lag, which is crucial for precise caramelization control. Infrared thermometers detect surface temperature without contact but can exhibit thermal lag due to emissivity variations and delayed heat transfer, potentially leading to less reliable caramelizing results.

Beam-spot size mismatch

Basic sugar thermometers provide precise internal temperature readings critical for achieving perfect caramelization stages, while infrared thermometers often face beam-spot size mismatch issues that can result in inaccurate surface temperature measurements due to their larger and fixed sensor area. This discrepancy makes infrared thermometers less reliable for small or unevenly heated caramelizing surfaces, where pinpoint accuracy is essential.

Sugar-syrup emissivity factor

When caramelizing, the accuracy of a basic sugar thermometer depends on direct contact with the syrup's temperature, avoiding emissivity-related errors common in infrared thermometers that measure surface radiation. Infrared thermometers often misread sugar syrup temperatures due to variable emissivity factors, which affect the accuracy of thermal readings on reflective or transparent sugar surfaces.

Non-intrusive temperature readout

An infrared thermometer provides a non-intrusive temperature readout by measuring the surface temperature of caramel without direct contact, ensuring precise monitoring without disturbing the cooking process. In contrast, a basic sugar thermometer requires immersion into the sugar mixture, which can affect temperature accuracy and potentially alter caramel consistency.

Real-time browning threshold

A basic sugar thermometer provides precise real-time temperature readings crucial for identifying the exact browning threshold during caramelizing, ensuring consistent sugar crystallization and desired color development. In contrast, an infrared thermometer offers non-contact surface temperature measurement but may lack accuracy on uneven or reflective caramel surfaces, potentially leading to less reliable detection of the critical browning point.

Basic sugar thermometer vs infrared thermometer for caramelizing. Infographic

cookingdiff.com

cookingdiff.com