Caramelizing pet through traditional methods often lacks consistency due to uneven heat application and risk of burning, whereas sous vide caramelization offers precise temperature control that enhances flavor development and texture. Sous vide allows for gradual, uniform caramelization, preserving the pet's natural moisture and preventing overcooking. This precision technique results in a more consistent, flavorful, and tender caramelized pet compared to conventional caramelizing methods.

Table of Comparison

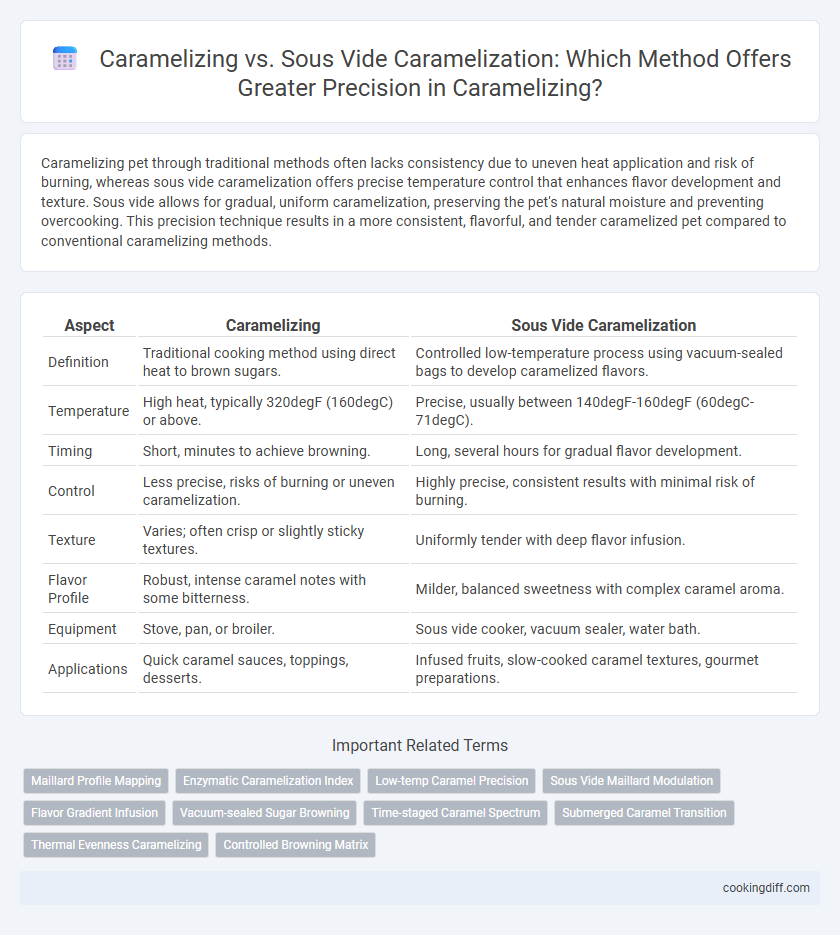

| Aspect | Caramelizing | Sous Vide Caramelization |

|---|---|---|

| Definition | Traditional cooking method using direct heat to brown sugars. | Controlled low-temperature process using vacuum-sealed bags to develop caramelized flavors. |

| Temperature | High heat, typically 320degF (160degC) or above. | Precise, usually between 140degF-160degF (60degC-71degC). |

| Timing | Short, minutes to achieve browning. | Long, several hours for gradual flavor development. |

| Control | Less precise, risks of burning or uneven caramelization. | Highly precise, consistent results with minimal risk of burning. |

| Texture | Varies; often crisp or slightly sticky textures. | Uniformly tender with deep flavor infusion. |

| Flavor Profile | Robust, intense caramel notes with some bitterness. | Milder, balanced sweetness with complex caramel aroma. |

| Equipment | Stove, pan, or broiler. | Sous vide cooker, vacuum sealer, water bath. |

| Applications | Quick caramel sauces, toppings, desserts. | Infused fruits, slow-cooked caramel textures, gourmet preparations. |

Understanding Caramelization in Cooking

Caramelizing involves heating sugar until it browns, creating deep flavors essential in cooking. Sous vide caramelization uses precise temperature control to achieve consistent results without burning.

- Caramelizing - This traditional method relies on direct heat to convert sugars into complex flavor compounds through Maillard and caramelization reactions.

- Sous Vide Caramelization - It uses controlled water bath temperatures to gently and uniformly brown sugars, preserving delicate flavors.

- Understanding Caramelization - Mastery of sugar chemistry and temperature control enhances texture and taste in culinary applications.

What Is Sous Vide Caramelization?

Sous vide caramelization involves cooking sugar or foods containing sugar in a precisely controlled water bath at lower temperatures than traditional caramelizing methods. This technique allows for even heat distribution and prevents burning, resulting in a more consistent and controlled caramelization process. Unlike conventional high-heat caramelizing, sous vide caramelization enhances flavor development while maintaining texture and moisture.

Science Behind Traditional Caramelizing

Traditional caramelizing involves heating sugar to trigger the Maillard reaction and pyrolysis, creating complex flavors and browning through the breakdown of sugars at approximately 320degF (160degC). This high-heat process causes rapid chemical changes, producing caramel's characteristic aroma and color but can be difficult to control precisely, often leading to uneven results or burning. Unlike sous vide caramelization, which uses controlled low temperatures to achieve uniform caramelization through enzymatic reactions, traditional methods rely on direct heat and precise timing for optimal sensory outcomes.

Sous Vide vs Conventional Heat Methods

Sous vide caramelization offers precise temperature control, allowing sugars to caramelize evenly without burning, unlike conventional heat methods that often result in uneven caramelization and increased risk of scorching. This precision ensures consistent texture and flavor development, enhancing the overall quality of culinary creations.

Conventional heat methods rely on high, direct heat which can cause rapid browning but lack the fine temperature regulation needed for delicate caramelization processes. Sous vide technology maintains a stable environment, facilitating gradual sugar transformation and superior control over Maillard reactions compared to traditional stovetop or oven techniques.

Temperature Control: Caramelizing vs Sous Vide

Caramelizing relies on direct high heat, often leading to less precise temperature control, which can result in uneven browning or burning. Sous vide caramelization maintains exact temperatures by immersing food in a water bath, allowing for consistent and uniform caramel development.

- Caramelizing Temperature Range - Typically occurs between 320degF and 350degF, with rapid temperature fluctuations due to direct heat exposure.

- Sous Vide Temperature Stability - Maintains precise temperatures around 320degF control within +-0.1degF, ensuring optimal caramel Maillard reactions without scorching.

- Impact on Flavor Development - Sous vide caramelization allows gradual sugar breakdown and complex flavor formation, while traditional caramelizing can create harsher, less controlled notes.

Flavor Profiles: Comparing Results

Caramelizing relies on direct heat to develop complex, rich flavors through Maillard reactions, creating deep, nutty, and sweet notes. Sous vide caramelization, by contrast, uses controlled low temperatures for prolonged times, resulting in uniformly tender textures and subtle, nuanced sweetness.

The flavor profiles from traditional caramelizing often feature bold, intense caramel notes and slight bitterness from higher temperatures. Sous vide maintains bright, clean caramel flavors with enhanced preservation of natural ingredient characteristics, promoting precision and consistency in taste.

Texture Differences Explained

How do texture differences manifest in caramelizing compared to sous vide caramelization? Traditional caramelizing produces a crisp, crunchy texture due to high heat inducing Maillard reactions on the surface. Sous vide caramelization offers a more uniform, tender texture by gently breaking down sugars and proteins at precise, controlled temperatures.

Best Uses for Each Technique

Caramelizing creates rich, complex flavors through high-heat cooking, ideal for quick browning of vegetables and meats. Sous vide caramelization offers precise temperature control, ensuring even sweetness development without burning or overcooking.

- Traditional Caramelizing - Best for developing deep, smoky notes on onions, sugar, and certain proteins with direct heat.

- Sous Vide Caramelization - Perfect for maintaining moisture and texture in delicate ingredients while achieving consistent caramelization.

- Flavor Control - Sous vide allows fine-tuning of sweetness levels, while traditional methods build layered, intense flavors.

Choosing between these techniques depends on the desired texture, flavor complexity, and cooking precision needed for the dish.

Equipment Needed for Precision Caramelization

Caramelizing requires a heavy-bottomed skillet or saute pan to evenly distribute heat for sugar browning, while sous vide caramelization demands a vacuum sealer and immersion circulator to maintain precise temperature control. Precision in caramelization is enhanced by the sous vide method, which allows consistent low-temperature cooking, preventing burnt or uneven caramel.

Sous vide caramelization equipment provides exact temperature settings, usually between 104degC and 114degC (219degF - 237degF), to optimize Maillard reactions and sugar melting without overcooking. The vacuum-sealed bags minimize moisture loss and flavor degradation, ensuring uniform caramel formation throughout the food. Traditional pans rely more on manual heat management, leading to variable caramel textures and increased risk of scorching.

Related Important Terms

Maillard Profile Mapping

Caramelizing involves high-heat cooking that triggers Maillard reactions, producing complex flavor compounds and a rich browning effect. Sous vide caramelization allows precise temperature control, enabling detailed Maillard profile mapping for consistent and targeted flavor development.

Enzymatic Caramelization Index

Caramelizing involves high heat application to induce Maillard reactions and sugar pyrolysis, whereas sous vide caramelization utilizes controlled low-temperature precision to optimize the Enzymatic Caramelization Index (ECI), preserving delicate sugars and enzymes for enhanced flavor development. The Enzymatic Caramelization Index quantifies the degree of enzymatic activity during caramelization, enabling chefs to achieve consistent, precise sweetness and color profiles unattainable through traditional high-heat methods.

Low-temp Caramel Precision

Low-temp caramel precision achieved through sous vide caramelization offers unparalleled control over Maillard reactions, ensuring consistent color and flavor development without the risk of burning inherent in traditional caramelizing methods. By maintaining precise temperatures typically between 90degC and 120degC, sous vide caramelization enhances sweetness and depth while preserving delicate aromatic compounds.

Sous Vide Maillard Modulation

Sous Vide Maillard Modulation offers unparalleled precision in caramelization by controlling temperature and time, preventing burning while enhancing complex flavor profiles. Unlike traditional caramelizing, sous vide allows consistent Maillard reactions at lower temperatures, resulting in evenly caramelized textures and intensified savory-sweet nuances.

Flavor Gradient Infusion

Caramelizing creates a rich, deep flavor through high-heat sugar oxidation, while sous vide caramelization enables precise temperature control for uniform flavor gradient infusion throughout the ingredient. This method enhances subtle sweet and savory notes by evenly distributing caramelized compounds, resulting in a more complex, balanced taste profile.

Vacuum-sealed Sugar Browning

Vacuum-sealed sugar browning in sous vide caramelization enables precise temperature control, preventing burning while achieving uniform caramelization. Traditional caramelizing relies on direct heat, which can cause uneven color and flavor development, making sous vide a superior method for consistent results.

Time-staged Caramel Spectrum

Caramelizing involves applying direct heat to sugar or food, producing a rich spectrum of flavors through precise time-staged browning, while sous vide caramelization allows controlled temperature settings to achieve uniform sweetness and texture over extended periods. The time-staged caramel spectrum in sous vide ensures consistent Maillard reaction stages, optimizing flavor development and preventing over-caramelization common in traditional methods.

Submerged Caramel Transition

Caramelizing involves applying direct heat to sugars, causing a Maillard reaction that develops deep amber flavors and a sticky texture, whereas sous vide caramelization utilizes precise temperature control in a water bath to achieve uniform caramel transition without burning. The submerged caramel transition in sous vide maintains consistent heat exposure, enabling gradual sugar breakdown and enhanced flavor complexity while preventing the uneven charring typical in traditional caramelizing methods.

Thermal Evenness Caramelizing

Caramelizing relies on direct heat, often causing uneven thermal distribution that can lead to inconsistent browning and flavor development. Sous vide caramelization offers superior thermal evenness by maintaining a controlled temperature environment, ensuring uniform caramelization and enhanced precision in flavor profile.

Caramelizing vs Sous Vide Caramelization for precision. Infographic

cookingdiff.com

cookingdiff.com