A flat whisk is ideal for caramelizing due to its broad, flat surface that efficiently scrapes the bottom of the pan, preventing sugar from burning. In contrast, a metal whisk with balloon-shaped wires may trap caramelized sugar, making stirring less effective and increasing the risk of uneven cooking. Choosing a flat whisk ensures smooth, consistent caramelization with minimal effort.

Table of Comparison

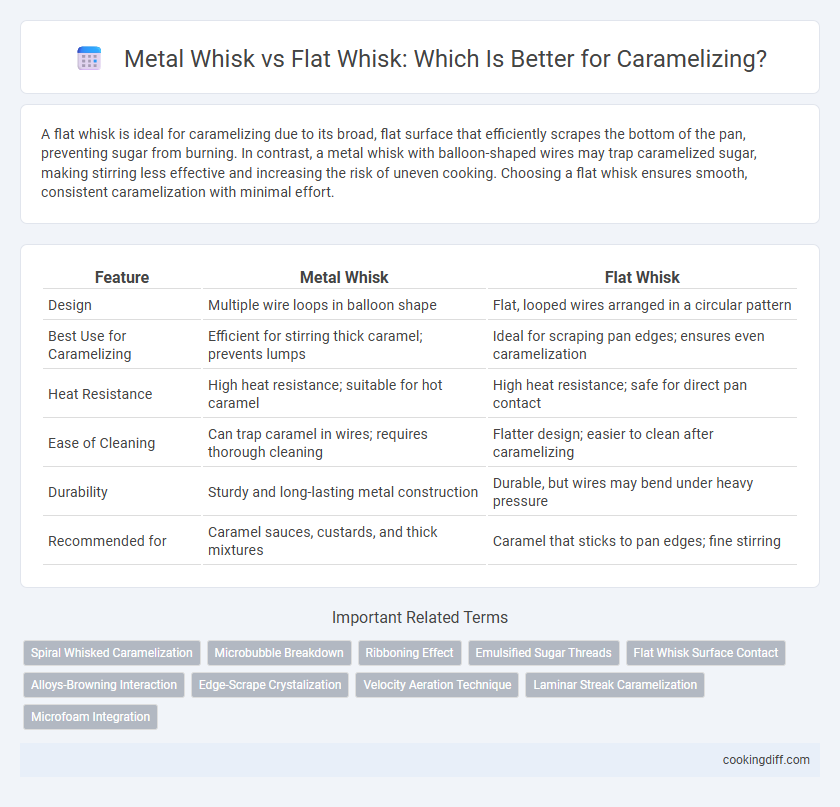

| Feature | Metal Whisk | Flat Whisk |

|---|---|---|

| Design | Multiple wire loops in balloon shape | Flat, looped wires arranged in a circular pattern |

| Best Use for Caramelizing | Efficient for stirring thick caramel; prevents lumps | Ideal for scraping pan edges; ensures even caramelization |

| Heat Resistance | High heat resistance; suitable for hot caramel | High heat resistance; safe for direct pan contact |

| Ease of Cleaning | Can trap caramel in wires; requires thorough cleaning | Flatter design; easier to clean after caramelizing |

| Durability | Sturdy and long-lasting metal construction | Durable, but wires may bend under heavy pressure |

| Recommended for | Caramel sauces, custards, and thick mixtures | Caramel that sticks to pan edges; fine stirring |

Understanding Caramelization: The Basics

Metal whisks, with their sturdy construction, efficiently distribute heat during caramelizing, ensuring even browning of sugars. Flat whisks excel in reaching corners and edges of pans, preventing hot spots that cause uneven caramel formation.

Understanding caramelization begins with recognizing the temperature control and surface contact; metal whisks handle high heat well without melting or warping. Flat whisks offer better scraping ability, crucial for constant agitation to avoid burning sugar during the caramelization process.

Metal Whisk vs Flat Whisk: Key Design Differences

Metal whisks feature multiple thin, rounded wires that allow for efficient aeration and smooth blending, ideal for caramelizing sauces that require constant stirring to prevent burning. Flat whisks consist of a flat, coiled wire design that provides better contact with the pan's surface, making them perfect for deglazing and evenly caramelizing sugars. The key design difference lies in the shape and wire arrangement, with metal whisks suited for whisking and flat whisks optimized for scraping and folding caramelized ingredients.

Why Tool Choice Matters for Caramelizing

Choosing between a metal whisk and a flat whisk significantly impacts the caramelizing process due to differences in heat conduction and surface contact. A metal whisk quickly distributes heat and prevents sugar crystallization, while a flat whisk efficiently scrapes the pan, ensuring even caramelization without burning.

- Metal Whisk enhances heat conduction - Its design allows rapid heat transfer, aiding faster sugar melting and caramel formation.

- Flat Whisk improves pan contact - The flat shape effectively scrapes the bottom, reducing the risk of burnt caramel.

- Tool choice affects texture and consistency - Using the appropriate whisk ensures smooth, evenly caramelized results critical for high-quality desserts.

Selecting the right whisk is essential for achieving perfect caramelization and optimal flavor development.

Metal Whisk Benefits for Caramelizing Sugar

Metal whisks offer excellent heat resistance, making them ideal for caramelizing sugar without melting or warping. Their thin, sturdy wires quickly incorporate sugar crystals, promoting even caramelization and preventing clumps. The durability and precision of metal whisks ensure consistent texture and color, essential for perfect caramel sauce.

Flat Whisk Advantages in the Caramelization Process

The flat whisk excels in caramelizing by efficiently scraping the pan surface, preventing sugar from burning and ensuring even heat distribution. Its design allows better control over stirring viscous sugar mixtures compared to a metal whisk.

- Superior surface contact - The flat whisk's shape maximizes contact with the pan, enabling thorough scraping and reducing caramel clumps.

- Enhanced heat regulation - Continuous movement of sugar with a flat whisk promotes uniform caramelization without hotspots.

- Improved consistency - Flat whisk prevents crystallization by keeping sugar moving seamlessly throughout the cooking process.

Comparing Control and Consistency: Metal vs Flat Whisk

The metal whisk provides superior control when caramelizing due to its rigid structure, allowing for precise stirring and preventing sugar clumps. Its narrow design ensures consistent heat distribution, essential for achieving an even caramel color.

The flat whisk, with its wider surface area, excels in scraping the pan's edges, reducing the risk of burning, but offers less precision in stirring. While it promotes consistent mixing, it may not deliver the same level of control as a metal whisk during delicate caramelization stages.

Ease of Stirring: Which Whisk Prevents Burning?

Which whisk is easier to use for preventing burning while caramelizing? A flat whisk offers better surface contact and reduces the risk of caramel sticking and burning due to its wide, flat blades. Metal whisks, while effective for mixing, can trap caramel in tight wire spaces, increasing the chance of scorching during the stirring process.

Cleaning and Durability: Metal vs Flat Whisk After Caramelizing

Metal whisks, with their durable stainless steel construction, resist staining and are easier to clean after caramelizing, as caramel often hardens on the surface. Flat whisks, although effective in scraping the pan, can trap caramel residue in their wider spaces, making thorough cleaning more challenging.

Durability favors metal whisks due to their robust build that withstands the high temperatures involved in caramelizing without warping. Flat whisks may bend or lose shape over time when exposed to the sticky, hardened caramel, reducing their lifespan. Regular cleaning immediately after caramelizing prevents residue from becoming difficult to remove on both whisk types, but metal versions maintain their integrity longer under frequent heavy use.

Expert Opinions: Professional Chefs’ Preferences

| Expert Opinions | Professional chefs often prefer flat whisks for caramelizing due to their ability to scrape the pan's surface effectively, preventing burning and ensuring smooth, even caramelization. Metal whisks, while durable, tend to incorporate too much air, which can interfere with the glossy texture desired in caramel. Culinary experts emphasize the flat whisk's design as optimal for combining ingredients at high temperatures without compromising texture. |

Related Important Terms

Spiral Whisked Caramelization

Spiral whisks excel in caramelizing by providing superior control over heat distribution and preventing crystallization through consistent, gentle mixing. Unlike flat whisks, spiral whisks reach deeper into pans, ensuring even caramelization and smoother, lump-free caramel textures.

Microbubble Breakdown

Metal whisks create more efficient microbubble breakdown during caramelizing due to their rigid, slender wires that vigorously agitate the sugar mixture, promoting uniform heat distribution and preventing crystallization. Flat whisks, while useful for shallow pans, generate fewer microbubbles and less turbulence, resulting in slower caramelization and increased risk of uneven heating.

Ribboning Effect

Metal whisks create a more pronounced ribboning effect when caramelizing by incorporating air and allowing the caramel to form thick, flowing ribbons, enhancing texture and appearance. Flat whisks, while effective for stirring, produce less aeration and a weaker ribboning effect, making metal whisks the preferred choice for achieving glossy, well-textured caramel.

Emulsified Sugar Threads

A metal whisk with thin, sturdy wires excels at creating emulsified sugar threads during caramelizing by efficiently aerating and blending hot sugar without breaking delicate strands. Flat whisks, with their wider surface area, may disrupt the formation of fine sugar threads, making metal whisks the preferred choice for achieving smooth, stable caramel emulsions.

Flat Whisk Surface Contact

A flat whisk provides superior surface contact for caramelizing, allowing more even heat distribution and efficient stirring of sugar as it melts, which reduces the risk of burning. Unlike a metal whisk, the flat whisk's shape ensures thorough scraping of the pan's edges, preventing crystallization and promoting smooth caramel formation.

Alloys-Browning Interaction

Metal whisks made from stainless steel alloys excel in caramelizing due to superior heat conduction and resistance to browning, ensuring even caramel development without unwanted sticking or burning. Flat whisks, while effective for mixing, offer less surface contact and heat transfer, leading to slower Maillard reactions and less consistent caramelization compared to metal alloys optimized for heat interaction.

Edge-Scrape Crystalization

A flat whisk with its thin, sharp edges excels at scraping the sides of the pan to prevent sugar crystallization during caramelizing, ensuring a smooth, glossy caramel. In contrast, a metal whisk's round wires are less effective at edge-scraping, increasing the risk of uneven caramel formation and unwanted grainy texture.

Velocity Aeration Technique

Using a metal whisk for caramelizing enhances the Velocity Aeration Technique by efficiently incorporating air into the sugar mixture, promoting even caramelization and a smoother texture. In contrast, a flat whisk distributes heat more slowly, limiting aeration and resulting in a denser caramel consistency.

Laminar Streak Caramelization

A flat whisk creates laminar streaks more efficiently during caramelizing by providing even contact and smooth stirring, which prevents localized burning and promotes uniform browning. Metal whisks, while durable, often produce uneven agitation in caramel, increasing the risk of crystallization and inconsistent caramel color development.

Metal Whisk vs Flat Whisk for caramelizing. Infographic

cookingdiff.com

cookingdiff.com