Traditional stoves provide steady and predictable heat, making them suitable for slow and even caramelizing processes. Induction burners offer precise temperature control and rapid heat adjustments, reducing the risk of burning caramel. Choosing between the two depends on the desired control level and cooking speed for perfect caramelization.

Table of Comparison

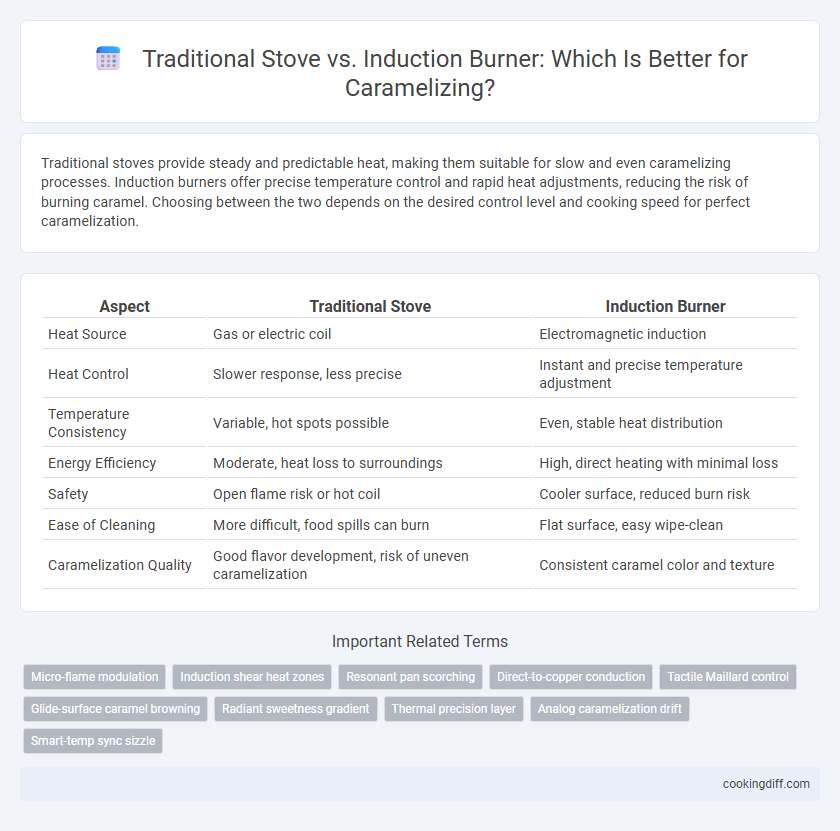

| Aspect | Traditional Stove | Induction Burner |

|---|---|---|

| Heat Source | Gas or electric coil | Electromagnetic induction |

| Heat Control | Slower response, less precise | Instant and precise temperature adjustment |

| Temperature Consistency | Variable, hot spots possible | Even, stable heat distribution |

| Energy Efficiency | Moderate, heat loss to surroundings | High, direct heating with minimal loss |

| Safety | Open flame risk or hot coil | Cooler surface, reduced burn risk |

| Ease of Cleaning | More difficult, food spills can burn | Flat surface, easy wipe-clean |

| Caramelization Quality | Good flavor development, risk of uneven caramelization | Consistent caramel color and texture |

Introduction to Caramelizing: Traditional vs Induction Methods

Caramelizing involves heating sugar until it melts and transforms into a rich, golden-brown syrup. Traditional stoves use direct flame or electric coils, while induction burners employ electromagnetic fields for rapid, even heating.

- Traditional Stoves - Provide gradual heat control but may result in uneven caramelization due to fluctuating temperatures.

- Induction Burners - Offer precise temperature control and faster heat adjustments for consistent caramelizing results.

- Heat Distribution - Induction burners ensure uniform heat across the pan, reducing the risk of burning compared to traditional stoves.

Heat Control: Precision on Traditional Stoves and Induction Burners

Induction burners offer precise and instant heat control ideal for caramelizing sugar evenly without burning. Traditional stoves provide less precise heat adjustments, potentially causing uneven caramelization and hotspots.

- Instant Heat Adjustment - Induction burners change temperature almost immediately, allowing for quick responses during caramelization.

- Consistent Temperature - Traditional stoves often have fluctuating heat, making it harder to maintain the constant low heat needed for perfect caramelization.

- Energy Efficiency - Induction burners use electromagnetic heat directly on the pan, leading to less energy wastage and more effective heating during caramelizing.

Precise heat control on induction burners makes them superior for consistently achieving the ideal caramelized texture and color.

Response Time: Heating Speed Comparison

Induction burners heat cookware directly through electromagnetic energy, resulting in significantly faster response times compared to traditional stoves that rely on gas or electric coil heating elements. This rapid heating capability allows for more precise control over the caramelization process, reducing the risk of burning sugar. Traditional stoves typically exhibit slower temperature adjustments, which can lead to uneven caramelization and longer cooking times.

Evenness of Caramelization: Distribution of Heat

Traditional stoves use gas or electric coils that provide uneven heat distribution, often causing hotspots that can lead to inconsistent caramelization. This uneven heat can result in parts of the sugar mixture burning while others remain undercooked.

Induction burners deliver precise, consistent heat through electromagnetic fields, ensuring an even temperature across the pan's surface for uniform caramelization. This controlled heat distribution minimizes the risk of burning and enhances the quality of caramelized dishes.

Energy Efficiency in Caramelizing Techniques

Induction burners provide superior energy efficiency compared to traditional stoves by directly heating the cookware through magnetic induction, reducing heat loss. This efficiency results in faster caramelization and less energy consumption.

- Direct Heat Transfer - Induction burners heat the pan directly, minimizing energy wasted on heating the air or stovetop surface.

- Faster Temperature Response - The rapid adjustment of heat on induction burners allows precise control during the caramelization process.

- Lower Energy Consumption - Induction cooktops typically use 84%-90% of the energy for cooking, whereas traditional stoves average around 40%-55%.

Safety Concerns: Traditional Stove vs Induction Burner

Which heating method offers greater safety when caramelizing, a traditional stove or an induction burner? Induction burners provide enhanced safety by using magnetic fields to heat the cookware directly, reducing the risk of open flames and accidental burns common with traditional gas or electric stoves. Traditional stoves pose higher fire hazards and can cause uneven heating, increasing the danger of sugar burning or splattering during caramelization.

Compatibility of Cookware for Caramelization

| Traditional stoves support a wide range of cookware materials including copper, cast iron, stainless steel, and aluminum, allowing optimal caramelization due to even heat distribution. Induction burners require cookware with magnetic properties, such as cast iron or magnetic stainless steel, to enable efficient caramelization without overheating or uneven cooking. Using incompatible cookware on induction burners can lead to poor caramelization results and potential damage to both the cookware and the burner itself. |

Maintenance and Cleaning After Caramelizing

Traditional stoves require regular cleaning of cast iron or stainless steel surfaces after caramelizing, as sugar residues can cause stubborn stains and burnt spots. Induction burners feature smooth glass tops that are easier to wipe clean immediately after use, minimizing residue buildup.

Maintenance for traditional stoves involves scrubbing and sometimes soaking pans to remove hardened caramel, which can be time-consuming and prone to damaging cookware surfaces. Induction burners prevent direct heat contact, reducing pan discoloration and making post-caramelizing cleanup faster and less labor-intensive. Regular wiping of the glass surface with non-abrasive cleaners maintains the induction burner's efficiency and appearance over time.

Flavor and Texture Results: Side-by-Side Analysis

Traditional stoves provide uneven heat distribution, which can lead to inconsistent caramelization and a less uniform texture in desserts. Induction burners offer precise temperature control, resulting in a more consistent caramelization that enhances the depth of flavor and creates a smoother texture. Side-by-side analysis shows induction burners yield a richer, more complex caramel flavor with optimal texture development compared to traditional stoves.

Related Important Terms

Micro-flame modulation

Traditional stoves offer limited micro-flame modulation, making precise temperature control for caramelizing sugar challenging and increasing the risk of burning. Induction burners provide rapid, accurate micro-flame modulation with instant heat adjustments, enabling consistent caramelization and reducing the likelihood of scorching.

Induction shear heat zones

Induction burners provide precise control over shear heat zones, enabling uniform and rapid caramelization by concentrating heat directly on the cookware surface, unlike traditional stoves which disperse heat less efficiently and cause uneven caramelizing. This focused heat reduces the risk of burning sugar while achieving consistent browning and enhanced flavor development in caramelization processes.

Resonant pan scorching

Traditional stoves often cause uneven heat distribution, increasing the risk of resonant pan scorching when caramelizing sugar, which can burn the caramel and impart a bitter taste. Induction burners provide precise, consistent heat control that minimizes hot spots, reducing the likelihood of pan scorching and resulting in smoother, perfectly caramelized sugar.

Direct-to-copper conduction

Traditional stoves rely on gas or electric coils that provide less precise heat control, often leading to uneven caramelization due to inconsistent direct-to-copper conduction. Induction burners generate heat through electromagnetic fields directly within copper cookware, enabling faster, more uniform caramelization with superior temperature accuracy and energy efficiency.

Tactile Maillard control

Traditional stoves provide uneven heat distribution, making tactile Maillard reaction control during caramelizing more challenging and prone to hot spots. Induction burners offer precise and consistent temperature adjustments, allowing for superior tactile feedback and more accurate management of caramelization processes.

Glide-surface caramel browning

Induction burners provide precise temperature control and consistent heat distribution, promoting even glide-surface caramel browning without hot spots common in traditional stoves. Traditional stoves often cause uneven heat zones, leading to irregular caramelization and increased risk of burning on the pan's surface.

Radiant sweetness gradient

Traditional stoves distribute heat unevenly, creating a radiant sweetness gradient that can lead to inconsistent caramelization with spots of burned or undercooked sugar. Induction burners offer precise, uniform heat control, resulting in a smooth, even caramelization process that enhances the full spectrum of caramel flavors.

Thermal precision layer

Traditional stoves offer uneven heat distribution that can cause inconsistent caramelization, while induction burners provide precise thermal control with rapid and uniform heating. This thermal precision layer in induction cooktops ensures optimal temperature management, reducing the risk of burning sugar and achieving perfect caramelization.

Analog caramelization drift

Traditional stoves often produce an analog caramelization drift due to uneven heat distribution, which can result in inconsistent browning and flavor development. In contrast, induction burners offer precise temperature control and rapid heat adjustments, minimizing caramelization drift and ensuring uniform caramelization throughout the cooking process.

Traditional stove vs induction burner for caramelizing. Infographic

cookingdiff.com

cookingdiff.com