Caramelizing under a broiler creates a quick, intense heat that evenly crisps the surface, ideal for achieving a deep, golden crust on pet foods. Using a culinary iron offers precise control, pressing heat directly onto the surface to develop a thicker, more textured caramelized layer. Both methods enhance flavor by breaking down sugars, but the broiler provides broader coverage while the culinary iron ensures targeted crust formation.

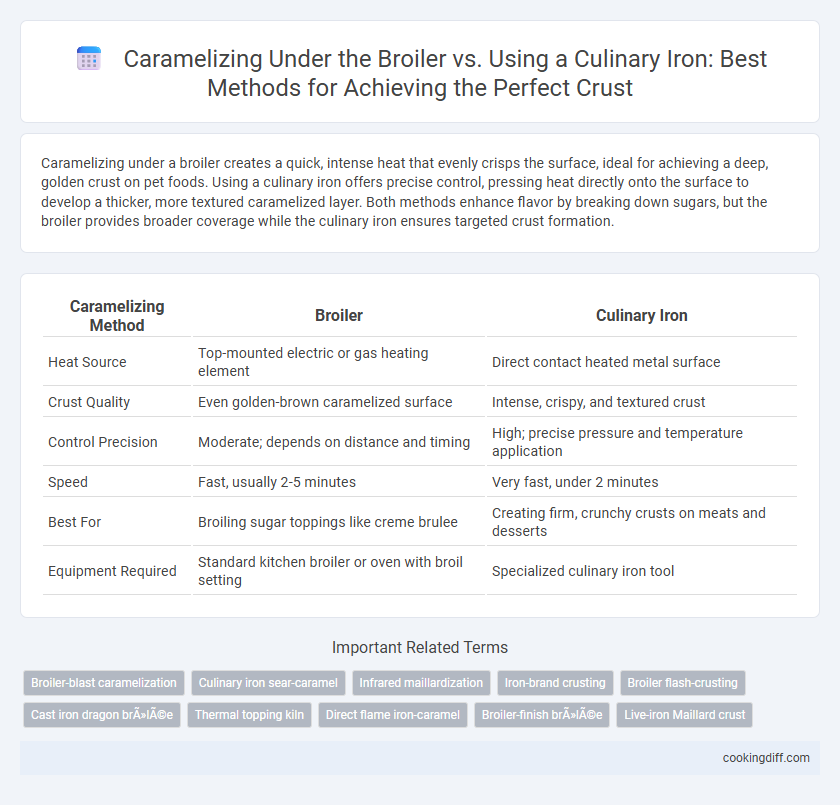

Table of Comparison

| Caramelizing Method | Broiler | Culinary Iron |

|---|---|---|

| Heat Source | Top-mounted electric or gas heating element | Direct contact heated metal surface |

| Crust Quality | Even golden-brown caramelized surface | Intense, crispy, and textured crust |

| Control Precision | Moderate; depends on distance and timing | High; precise pressure and temperature application |

| Speed | Fast, usually 2-5 minutes | Very fast, under 2 minutes |

| Best For | Broiling sugar toppings like creme brulee | Creating firm, crunchy crusts on meats and desserts |

| Equipment Required | Standard kitchen broiler or oven with broil setting | Specialized culinary iron tool |

Introduction to Caramelizing Techniques

Caramelizing under a broiler uses intense, direct heat from above to quickly brown sugars and create a crisp, flavorful crust on foods like creme brulee. Culinary irons, designed specifically for caramelizing, apply steady, precise heat directly to the surface, ensuring uniform caramelization and a perfect crust. Both techniques enhance texture and flavor but differ in heat delivery and control, making them suitable for different culinary applications.

What is Broiler Caramelization?

Broiler caramelization involves exposing food to high, direct heat from an oven's broiler element, which rapidly browns the surface by caramelizing sugars and proteins. This method creates a crunchy, flavorful crust while preserving the interior's moisture, commonly used for dishes like creme brulee or glazed vegetables. Compared to caramelizing with a culinary iron, broiler caramelization offers even heat distribution but less precision for targeted browning on specific areas of the crust.

Understanding Culinary Iron Caramelization

Caramelizing with a culinary iron offers precise control over temperature and direct application, creating a uniform, deeply browned crust that intensifies flavor. Broiler caramelization relies on radiant heat from above, which can lead to uneven browning and less control over crust thickness.

- Precision heat control - Culinary irons maintain consistent temperatures for even caramelization without burning.

- Targeted application - Heat is applied directly to the surface, enhancing crust development and flavor concentration.

- Broiler limitations - Uneven heat distribution under a broiler can cause patchy caramelization and requires monitoring to prevent charring.

Comparing Crust Formation: Broiler vs Culinary Iron

| Method | Crust Formation | Advantages |

|---|---|---|

| Broiler | Even caramelization with quick, intense heat creating a golden-brown crust over the surface | Allows uniform exposure to high heat, suitable for large or unevenly shaped foods |

| Culinary Iron | Direct, concentrated heat produces a thicker, more textured crust with distinct caramelized patterns | Enables precise control of crust thickness and depth, ideal for decorative or highly textured finishes |

Temperature Control and Precision in Each Method

Caramelizing under a broiler offers high heat exposure, typically around 500degF, enabling rapid sugar browning but with less precise temperature control, which can risk uneven caramelization or burning. This method excels in quick surface crust formation on dishes like creme brulee but demands close attention to prevent scorching.

Caramelizing with a culinary iron employs direct contact heat, usually in the 350degF to 450degF range, allowing greater precision and consistent temperature control for forming a uniform crust. This technique enhances caramelization by evenly distributing heat and providing tactile feedback to adjust pressure and timing, ideal for delicate or intricate caramel finishes.

Flavor Profiles Achieved: Broiler vs Culinary Iron

Caramelizing under a broiler produces a uniform, intense caramelized crust with distinct smoky undertones due to high radiant heat exposure, enhancing depth and complexity. In contrast, caramelizing with a culinary iron delivers localized, precise caramelization, creating a varied texture and a more nuanced flavor profile with subtle toasty notes.

- Broiler caramelizing - Achieves consistent color and flavor intensity across the surface.

- Culinary iron caramelizing - Allows for controlled, spot-specific caramelization enhancing texture contrast.

- Flavor complexity - Broiler imparts bold smokiness while culinary iron yields delicate toasted sweetness.

The choice between broiler and culinary iron caramelizing influences the crust's flavor dynamics and texture sophistication.

Surface Texture Differences in Caramelized Crusts

How do surface textures differ when caramelizing under a broiler versus using a culinary iron for crust? Caramelizing under a broiler produces a more uneven, slightly crisp surface with varying shades of caramelization due to direct radiant heat. Using a culinary iron creates a uniform, intensely browned crust with a consistent texture thanks to the controlled, even pressure applied during caramelization.

Time and Efficiency: Which Method Wins?

Caramelizing under a broiler typically takes 3 to 5 minutes, providing a quick and even crust on the surface of foods with minimal monitoring. This method leverages intense, direct heat from above to swiftly melt sugar and create a golden-brown caramel layer.

Caramelizing with a culinary iron requires slightly more time and precision, as the iron must be heated appropriately and applied carefully to achieve a consistent crust without burning. This technique offers greater control over the caramelization area, making it efficient for detailed finishing touches on desserts or meats. While it may be less time-efficient for large quantities, the culinary iron excels in precision and customization for gourmet presentations.

Best Foods for Each Caramelizing Technique

Broiler caramelizing is ideal for dishes like creme brulee and roasted vegetables, where high, direct heat quickly melts sugar to create a crisp, golden crust. This technique is best suited for foods that can withstand intense heat without burning, such as fruits, custards, and thin cuts of meat.

Culinary iron caramelizing excels with proteins like steaks, scallops, and pork chops, producing an even, deeply seared crust through direct contact heat. This method is perfect for thicker cuts of meat and foods requiring precision caramelization without overcooking the interior.

Related Important Terms

Broiler-blast caramelization

Broiler-blast caramelization produces intense, high heat directly on the surface, creating a deeply charred crust that enhances complex flavors and crisp texture more rapidly than the controlled, even searing of a culinary iron. Unlike the uniform caramel crust from a culinary iron, broiler caramelizing develops bold, smoky notes and a visually striking finish ideal for robust dishes requiring quick, dramatic caramel development.

Culinary iron sear-caramel

Caramelizing with a culinary iron creates a precise, high-heat sear that forms an evenly crisp and flavorful crust, enhancing Maillard reactions more effectively than a broiler. Unlike broiling, which relies on indirect heat and can result in uneven caramelization, the culinary iron provides consistent contact heat, optimizing texture and taste in crust development.

Infrared maillardization

Caramelizing under a broiler uses intense radiant heat to quickly induce Maillard reactions on the surface, resulting in a sweet, crispy crust through infrared radiation. Culinary irons concentrate heat directly onto the food's surface, providing precise control for consistent infrared Maillardization and an evenly caramelized crust without overcooking the interior.

Iron-brand crusting

Caramelizing with a culinary iron creates a precise, evenly browned crust with enhanced Maillard reaction flavor development, outperforming the often uneven heat distribution and occasional charring risks of broiler caramelizing. The Iron-brand crusting tool delivers consistent high heat directly to the surface, producing a superior texture and deeper caramelization ideal for professional-grade finishing.

Broiler flash-crusting

Broiler flash-crusting caramelizes sugars rapidly under intense, direct heat, creating a crisp, evenly browned layer that locks in moisture. In contrast, culinary irons apply localized, high-pressure heat for precise crust formation but lack the broad, quick surface coverage achieved by broilers.

Cast iron dragon brûlée

Caramelizing under a broiler delivers intense, direct heat ideal for achieving an evenly browned crust but may lack precision in heat control, risking uneven caramelization. Using a cast iron culinary iron like the cast iron dragon brulee offers consistent, controlled heat to create a thick, crisp caramelized crust with deep flavor layers and minimal burning.

Thermal topping kiln

Caramelizing under a broiler uses intense radiant heat to quickly brown sugars and form a crisp crust, but it can be uneven and less controllable compared to a culinary iron. The thermal topping kiln in the culinary iron provides consistent, direct contact heat for precise caramelization, resulting in an evenly crisp and flavorful crust ideal for delicate desserts and proteins.

Direct flame iron-caramel

Direct flame iron-caramel techniques produce a deeply textured caramel crust by applying intense, focused heat that rapidly melts sugars on the surface, creating a rich, smoky flavor distinct from the more uniform browning achieved under a broiler. This method enhances the Maillard reaction, yielding a crisp, crackling layer that intensifies the depth and complexity of dishes like creme brulee or roasted vegetables.

Broiler-finish brûlée

Broiler caramelizing offers intense, direct heat that quickly forms a crisp, golden crust ideal for a broiler-finish brulee, providing even caramelization with minimal effort. Culinary iron caramelizing applies uniform pressure and heat for a thicker, more controlled crust but lacks the rapid, high-temperature searing effect essential for traditional brulee texture and flavor.

Caramelizing under broiler vs Caramelizing with culinary iron for crust. Infographic

cookingdiff.com

cookingdiff.com