A copper sugar pan provides superior heat conductivity and precise temperature control, essential for achieving the perfect caramel consistency without burning. Classic saucepans, often made from stainless steel or aluminum, heat less evenly, increasing the risk of hot spots and uneven caramelization. For professional caramelizing, the copper pan's responsiveness ensures smoother, more consistent results compared to a standard saucepan.

Table of Comparison

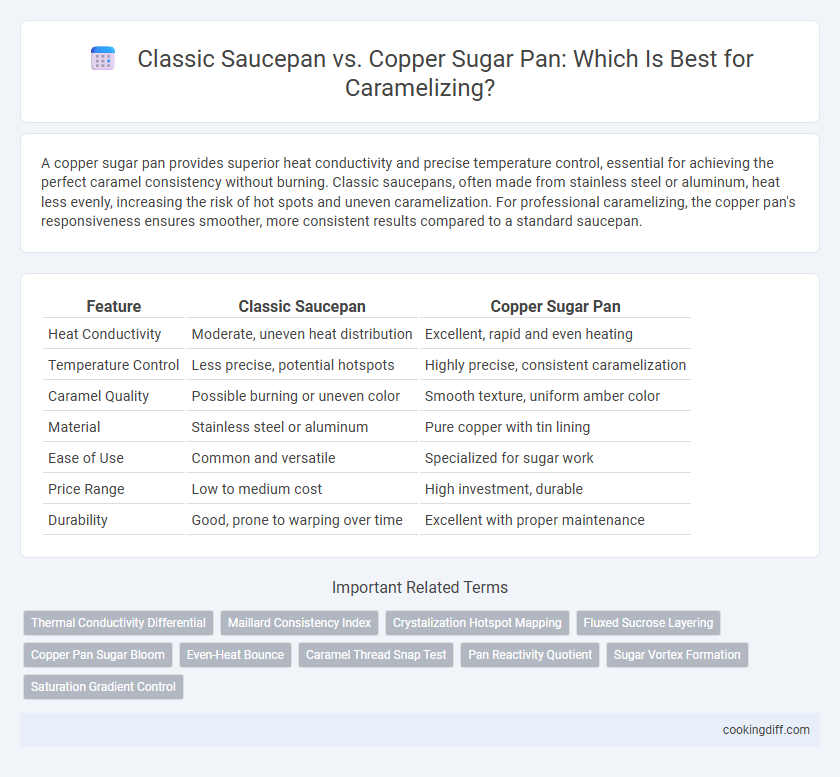

| Feature | Classic Saucepan | Copper Sugar Pan |

|---|---|---|

| Heat Conductivity | Moderate, uneven heat distribution | Excellent, rapid and even heating |

| Temperature Control | Less precise, potential hotspots | Highly precise, consistent caramelization |

| Caramel Quality | Possible burning or uneven color | Smooth texture, uniform amber color |

| Material | Stainless steel or aluminum | Pure copper with tin lining |

| Ease of Use | Common and versatile | Specialized for sugar work |

| Price Range | Low to medium cost | High investment, durable |

| Durability | Good, prone to warping over time | Excellent with proper maintenance |

Introduction to Caramelizing: The Science Behind Sugar Transformation

Classic saucepans, typically made from stainless steel or aluminum, offer even heat distribution but may risk uneven caramelization due to slower temperature changes. Copper sugar pans excel in precise temperature control and rapid heat response, crucial for achieving the perfect caramel texture and color through controlled sugar transformation. The superior thermal conductivity of copper ensures consistent caramelization by preventing hotspots and enabling smooth sugar melting during the Maillard reaction and caramelization process.

Why Pan Choice Matters for Caramelization

| Classic Saucepan | Typically made from stainless steel or aluminum, these pans offer even heat distribution but can create hot spots, potentially causing uneven caramelization; their thicker base helps maintain consistent temperature throughout the cooking process. |

| Copper Sugar Pan | Known for superior thermal conductivity, copper pans heat quickly and cool down rapidly, allowing precise temperature control essential for perfect caramelization; their responsiveness prevents sugar from burning and ensures smooth, uniform caramel texture. |

| Why Pan Choice Matters | The pan's material impacts heat distribution and temperature control, critical factors for caramelization that affect sugar's melting, browning, and flavor development; copper sugar pans minimize the risk of burning, enabling delicate caramelization that enhances flavor depth. |

Classic Saucepan: Common Features and Materials

Classic saucepans for caramelizing are typically made from stainless steel or aluminum, offering even heat distribution and durability. They usually feature a heavy-bottom design to prevent hot spots and ensure consistent caramelization.

These saucepans often come with a long handle for safe handling and a non-reactive surface to avoid altering the sugar's flavor. Their versatility makes them suitable for various cooking tasks beyond caramelizing, such as making sauces and boiling liquids.

Copper Sugar Pan: Unique Attributes and Benefits

Copper sugar pans offer exceptional thermal conductivity, ensuring even heat distribution crucial for precise caramelization. Their superior heat responsiveness allows rapid temperature adjustments, minimizing the risk of burning sugar.

Unlike classic saucepans, copper pans maintain consistent heat without hot spots, enhancing caramel color and flavor development. The material's durability and elegant patina also provide both functional and aesthetic advantages for caramelizing tasks.

Heat Conductivity: Comparing Evenness and Responsiveness

A classic saucepan offers moderate heat conductivity, resulting in slower, less uniform caramelization. Copper sugar pans excel with superior heat responsiveness and even heat distribution, minimizing burning risks and ensuring consistent caramel texture.

- Heat Conductivity - Copper pans conduct heat approximately 20 times better than stainless steel, facilitating precise temperature control.

- Evenness - Copper's uniform thermal distribution prevents hotspots that often cause uneven caramelization in classic saucepans.

- Responsiveness - Copper reacts faster to temperature changes allowing immediate adjustments essential for delicate sugar work.

Control Over Browning and Crystalization

Which provides better control over browning and crystallization: a classic saucepan or a copper sugar pan? Copper sugar pans offer superior heat conductivity, allowing precise temperature regulation essential for even caramelization and preventing crystallization. Classic saucepans tend to heat unevenly, increasing the risk of hot spots that cause uneven browning and sugar crystallization during caramel making.

Ease of Handling and Maneuverability

Classic saucepans offer straightforward handling with familiar shapes and handles, making them user-friendly for general caramelizing tasks. Copper sugar pans provide superior maneuverability due to their lightweight design and ergonomic handles, allowing precise control during the caramelization process.

- Classic Saucepan Stability - Heavier weight offers stable handling but can be cumbersome during constant stirring.

- Copper Pan Heat Responsiveness - Rapid heat conduction enables quick adjustments, enhancing control over caramel color.

- Copper Pan Ergonomics - Slim, long handles reduce hand fatigue and improve maneuverability when swirling sugar.

For ease of handling and precise caramelization, copper sugar pans typically outperform classic saucepans in professional kitchens.

Cleaning and Maintenance Differences

Classic saucepans often feature non-stick coatings that simplify cleaning after caramelizing, preventing sugar from hardening and sticking to the surface. Copper sugar pans require immediate cleaning to avoid tarnishing and are best washed by hand to maintain their conductivity and appearance.

Copper sugar pans demand careful maintenance, including regular polishing to prevent oxidation and ensure optimal heat distribution during caramelization. In contrast, classic saucepans are typically dishwasher safe, with less frequent need for deep cleaning. The higher durability and easier upkeep of classic saucepans make them practical for frequent caramelizing tasks, while copper pans excel in precise temperature control but need more attention to maintain their quality.

Which Pan for Which Recipe: Practical Recommendations

Choosing between a classic saucepan and a copper sugar pan depends on the recipe's precision and heat sensitivity. Copper pans offer superior heat conductivity and control for delicate caramel sauces, while classic saucepans are better for general caramelizing tasks with less temperature sensitivity.

- Copper Sugar Pan for Precision - Ideal for recipes requiring exact temperature control, such as sugar sculptures or candy making.

- Classic Saucepan for Versatility - Suitable for everyday caramel sauces and glazing with moderate heat management.

- Heat Distribution Considerations - Copper pans provide more even heating, reducing the risk of burning sugar compared to standard saucepans.

Related Important Terms

Thermal Conductivity Differential

Copper sugar pans offer superior thermal conductivity, heating evenly and allowing precise temperature control crucial for caramelizing sugar without burning. Classic saucepans, typically made from stainless steel or aluminum, have lower thermal conductivity, leading to uneven heat distribution and higher risk of hot spots during caramelization.

Maillard Consistency Index

Classic saucepans made from stainless steel often exhibit lower Maillard Consistency Index values due to uneven heat distribution, resulting in inconsistent caramelization. Copper sugar pans provide superior thermal conductivity, ensuring precise temperature control and a higher Maillard Consistency Index, which promotes uniform caramelization and enhanced flavor development.

Crystalization Hotspot Mapping

Classic saucepans often create uneven heat distribution leading to crystallization hotspots, while copper sugar pans provide superior thermal conductivity, ensuring more uniform caramelization and reduced sugar crystallization. This even heat transfer in copper pans prevents localized burning and promotes smoother texture in caramel products.

Fluxed Sucrose Layering

Copper sugar pans provide superior heat conductivity that ensures even caramelization and optimal fluxed sucrose layering, preventing hot spots and promoting consistent browning. Classic saucepans often result in uneven temperature distribution, leading to irregular caramel texture and increased risk of burning during the fluxed sucrose caramelization process.

Copper Pan Sugar Bloom

Copper sugar pans excel in caramelizing due to their superior heat conductivity and precise temperature control, which prevents sugar bloom and ensures a smooth, evenly caramelized result. Classic saucepans often cause uneven heating, increasing the risk of sugar bloom and resulting in a grainy or burnt caramel texture.

Even-Heat Bounce

Copper sugar pans provide superior even-heat bounce compared to classic saucepans, ensuring consistent temperature distribution critical for precise caramelizing. The high thermal conductivity of copper allows rapid and uniform heat response, reducing hot spots and preventing sugar from burning or crystallizing unevenly.

Caramel Thread Snap Test

Copper sugar pans heat evenly and respond quickly to temperature changes, allowing precise control during the caramel thread snap test, which is crucial for achieving the perfect caramel consistency. Classic saucepans may develop hot spots that cause uneven caramelization, increasing the risk of burning or undercooking the sugar syrup at the critical thread stage.

Pan Reactivity Quotient

Copper sugar pans have a lower pan reactivity quotient compared to classic saucepans, providing superior heat conductivity and precise temperature control essential for caramelizing sugar without burning or crystallization. Classic saucepans, often made from stainless steel or aluminum, exhibit higher reactivity, which can cause uneven heating and negatively impact caramel's texture and flavor.

Sugar Vortex Formation

Copper sugar pans create superior heat conductivity that promotes even sugar melting, facilitating the formation of a consistent sugar vortex during caramelizing. Classic saucepans often have uneven heat distribution, which can disrupt vortex stability and result in uneven caramel texture.

Classic saucepan vs copper sugar pan for caramelizing. Infographic

cookingdiff.com

cookingdiff.com