Caramelizing pet enhances flavor by slowly heating sugars to develop rich, complex notes, while pressure caramelization accelerates this process using high pressure and temperature, producing intense flavor in a fraction of the time. The pressure method locks in moisture and intensifies caramelization, offering a rapid yet deeply nuanced taste profile. Choosing between traditional caramelizing and pressure caramelization depends on desired flavor depth and time constraints.

Table of Comparison

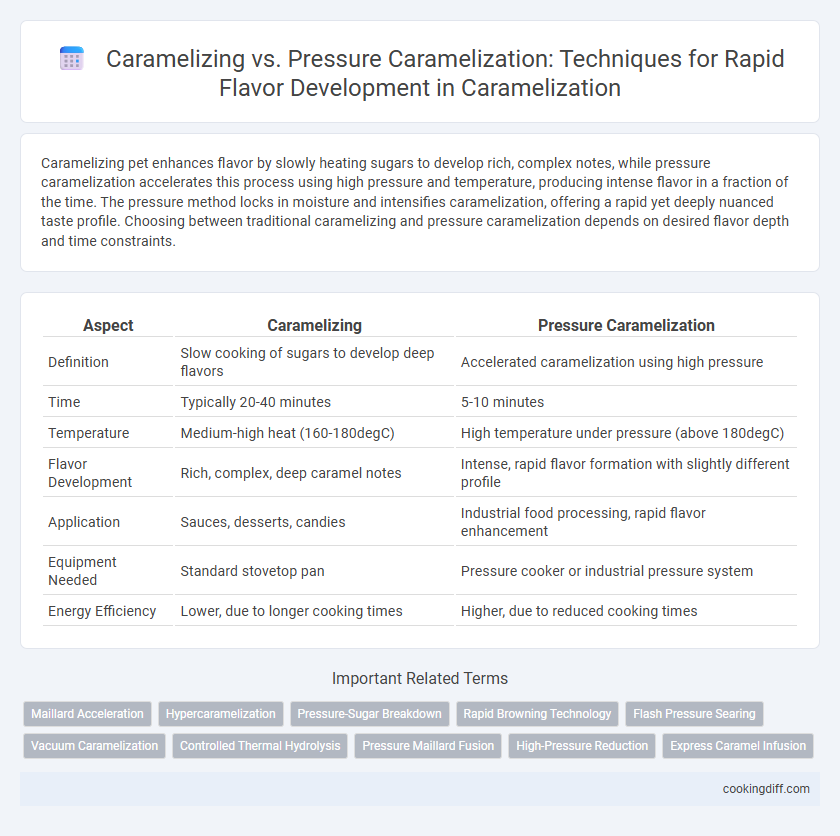

| Aspect | Caramelizing | Pressure Caramelization |

|---|---|---|

| Definition | Slow cooking of sugars to develop deep flavors | Accelerated caramelization using high pressure |

| Time | Typically 20-40 minutes | 5-10 minutes |

| Temperature | Medium-high heat (160-180degC) | High temperature under pressure (above 180degC) |

| Flavor Development | Rich, complex, deep caramel notes | Intense, rapid flavor formation with slightly different profile |

| Application | Sauces, desserts, candies | Industrial food processing, rapid flavor enhancement |

| Equipment Needed | Standard stovetop pan | Pressure cooker or industrial pressure system |

| Energy Efficiency | Lower, due to longer cooking times | Higher, due to reduced cooking times |

Introduction to Caramelization: Traditional vs. Pressure Methods

Caramelization is a chemical process where sugars are heated to create rich, complex flavors and a golden-brown color in foods. Traditional caramelizing uses direct heat over time, while pressure caramelization accelerates this reaction using controlled pressure and temperature for faster results.

- Traditional Caramelization - Involves slowly heating sugars at temperatures around 320degF (160degC) to develop deep flavors and color.

- Pressure Caramelization - Utilizes elevated pressure and temperature to speed up sugar breakdown, reducing cooking time significantly.

- Flavor Development - Pressure caramelization enhances flavor intensity rapidly, making it efficient for industrial food production compared to traditional methods.

The Science Behind Caramelization

How does caramelizing compare to pressure caramelization in enhancing flavor? Caramelizing involves slowly heating sugars to develop complex flavors through Maillard reactions and sugar breakdown, creating rich, deep caramel notes. Pressure caramelization accelerates this process by increasing temperature and pressure, yielding rapid flavor development without compromising the chemical reactions essential for caramel taste.

What Is Pressure Caramelization?

Pressure caramelization is a technique that accelerates the caramelization process by applying high pressure and temperature simultaneously, enhancing sugar breakdown and flavor development more rapidly than traditional methods. Unlike conventional caramelizing, which relies on heat over time, pressure caramelization uses a sealed environment to intensify chemical reactions, producing deeper, more complex caramel flavors in a fraction of the time. This method is particularly effective in industrial food production where efficiency and consistent flavor profiles are essential.

Flavor Development: Classic vs. Pressure Caramelization

Caramelizing enhances flavor through the Maillard reaction, developing complex sugars and rich, nutty notes over moderate heat and longer cooking times. Traditional caramelization results in a deep amber hue and layered taste that emphasizes natural sweetness and subtle bitterness.

Pressure caramelization accelerates flavor development by increasing temperature and pressure, producing intense, concentrated caramel flavors in a fraction of the time. This method preserves more volatile compounds, delivering vibrant taste profiles with intensified sweetness and reduced bitterness compared to classic techniques.

Time Efficiency: Which Method Is Faster?

Pressure caramelization significantly reduces the time required to develop rich caramel flavors compared to traditional caramelizing methods. This rapid process accelerates Maillard reactions and sugar breakdown, resulting in flavorful outcomes within minutes rather than hours.

- Pressure Caramelization is Faster - It uses high pressure and temperature to speed up caramel formation, cutting down cooking time drastically.

- Traditional Caramelizing Takes Longer - Conventional methods rely on gradual heating to melt and brown sugars over extended periods, often 30 minutes or more.

- Time Efficiency Enhances Productivity - Faster caramelization under pressure allows chefs to achieve deep flavors quickly, improving kitchen turnaround without compromising taste.

Equipment Needed for Each Caramelizing Technique

| Caramelizing | Pressure Caramelization |

|---|---|

| Traditional caramelizing requires a heavy-bottomed skillet or saute pan, a heat source, and optionally a wooden spoon or spatula to stir and control browning. | Pressure caramelization needs a pressure cooker or pressure-compatible pan, precise temperature control, and sturdy utensils capable of withstanding high pressure and heat. |

| The equipment focuses on even heat distribution to gently brown sugars and develop complex flavors over moderate heat and time. | The pressure cooker accelerates the Maillard reaction and sugar breakdown, requiring equipment designed for rapid, high-temperature cooking that minimizes moisture loss. |

| More accessible for home kitchens with standard cookware; skillful heat management is essential for flavor and color development. | Specialized equipment enhances rapid flavor development by intensifying caramelization reactions, suitable for commercial or experimental culinary settings. |

Texture and Appearance: Comparing Outcomes

Caramelizing typically produces a rich, deep brown color with a slightly crisp texture that enhances the sweetness and complexity of ingredients. Pressure caramelization accelerates the process, often resulting in a smoother, more uniform appearance with a softer texture due to the controlled moisture and heat. The choice between methods impacts the final dish's visual appeal and mouthfeel, making texture and appearance key factors in selecting the appropriate caramelization technique.

Ideal Foods for Pressure Caramelization

Pressure caramelization accelerates the development of rich, deep flavors compared to traditional caramelizing methods by using high temperature and pressure. Root vegetables, dense fruits, and meats are ideal for pressure caramelization as they withstand the intense conditions while enhancing their natural sweetness.

- Root Vegetables - Carrots and sweet potatoes soften quickly and develop complex sugars under pressure caramelization.

- Dense Fruits - Apples and pears retain structure and intensify flavor when pressure caramelized.

- Meats - Tough cuts benefit from pressure caramelization, resulting in tender meat with a rich, caramelized crust.

Pressure caramelization offers a rapid, efficient way to maximize flavor development in specific food types.

Common Mistakes and How to Avoid Them

Common mistakes in caramelizing include overheating the sugar, which causes burning and bitterness, and stirring too much, leading to crystallization. Maintaining a steady medium heat and allowing the sugar to melt undisturbed prevents these issues effectively.

Pressure caramelization often leads to uneven cooking if the pressure is not properly regulated, resulting in clumped or burnt caramel. Using a precise pressure cooker with monitored temperature helps achieve rapid, uniform caramelization without compromising flavor.

Related Important Terms

Maillard Acceleration

Caramelizing involves slow heat application to develop complex flavors through sugar breakdown, whereas pressure caramelization accelerates Maillard reactions by increasing temperature and pressure, resulting in rapid flavor enhancement. This method intensifies browning and deepens taste profiles more efficiently than traditional caramelization.

Hypercaramelization

Hypercaramelization enhances flavor intensity by accelerating the Maillard reaction using controlled high heat, producing deeper, more complex caramel notes compared to traditional caramelizing methods. Pressure caramelization further intensifies this process by trapping steam, increasing temperature and moisture retention, which rapidly develops rich, layered flavors in a fraction of the time.

Pressure-Sugar Breakdown

Pressure caramelization accelerates sugar breakdown by increasing temperature and pressure simultaneously, resulting in faster Maillard reactions and intensified caramel flavors. Traditional caramelizing relies on gradual heat, causing slower sugar decomposition and milder flavor development.

Rapid Browning Technology

Rapid Browning Technology accelerates caramelizing by applying high heat in a controlled environment, producing deep, rich flavors more quickly than traditional methods. Pressure caramelization intensifies Maillard reactions under elevated pressure, enhancing flavor development and color formation while reducing cooking time.

Flash Pressure Searing

Caramelizing enhances flavor by slowly browning sugars through controlled heat, while pressure caramelization accelerates this process using high-pressure steam to rapidly develop complex, rich flavors. Flash pressure searing combines intense heat and pressure to achieve a deeply caramelized crust in seconds, maximizing flavor depth and Maillard reaction efficiency without overcooking the interior.

Vacuum Caramelization

Vacuum caramelization accelerates flavor development by lowering the boiling point of sugars, enabling rapid caramelization at reduced temperatures without burning. Compared to traditional and pressure caramelization, vacuum caramelization ensures enhanced flavor clarity and uniform browning, optimizing sensory profiles in confectionery and food processing.

Controlled Thermal Hydrolysis

Caramelizing involves heating sugars gradually to develop complex flavors through Maillard reactions, while pressure caramelization accelerates this process by applying controlled thermal hydrolysis under elevated pressure, resulting in rapid flavor development with enhanced depth and reduced processing time. Controlled thermal hydrolysis optimizes molecular breakdown, producing richer caramel notes and superior consistency compared to traditional caramelizing methods.

Pressure Maillard Fusion

Pressure Maillard Fusion accelerates caramelizing by combining high heat and pressure to intensify flavor development through Maillard reactions, surpassing traditional caramelizing's slower sugar caramel breakdown. This method enhances rapid flavor generation by producing deeper browning and complex taste profiles within minutes, offering superior culinary efficiency and richness.

High-Pressure Reduction

High-pressure reduction accelerates caramelization by increasing temperature and pressure, intensifying Maillard reactions for rapid flavor development compared to traditional slow caramelizing. This method enhances color, aroma, and complexity in a fraction of the time, optimizing culinary processes and preserving delicate flavors.

Caramelizing vs Pressure Caramelization for rapid flavor. Infographic

cookingdiff.com

cookingdiff.com