Oven roasting promotes caramelization by applying dry heat, allowing natural sugars in vegetables to brown and develop deep, complex flavors. High-pressure steam caramelization uses moist heat under pressure, which can soften vegetables quickly but often results in less pronounced caramelization and a milder taste. Choosing oven roasting enhances texture and intensifies sweetness, while high-pressure steam offers faster cooking with gentler flavor development.

Table of Comparison

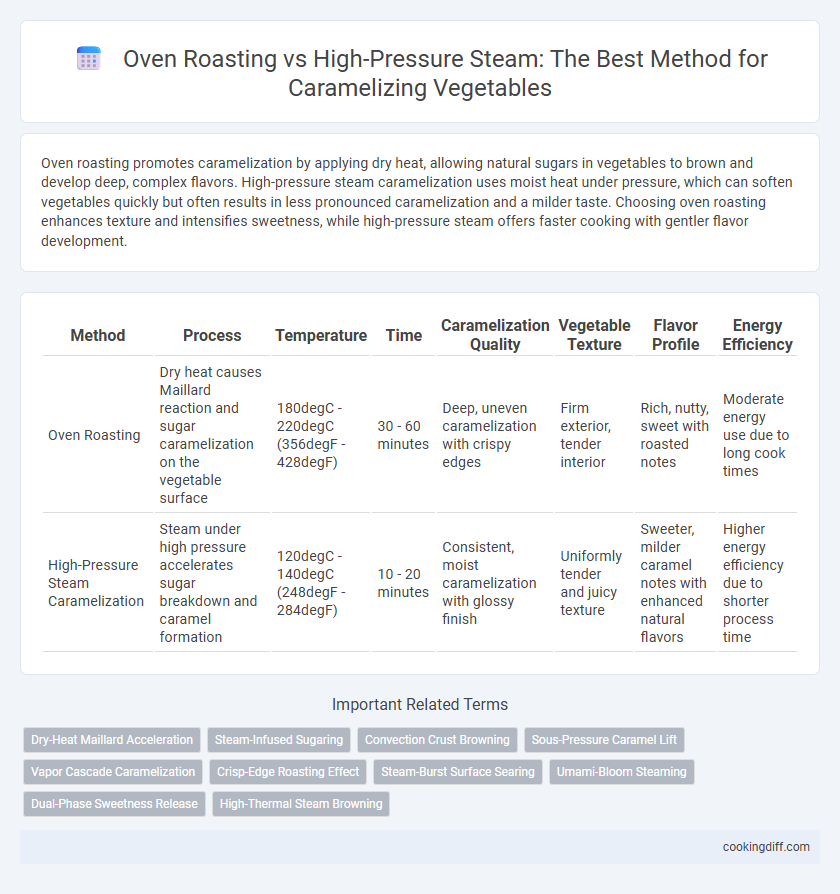

| Method | Process | Temperature | Time | Caramelization Quality | Vegetable Texture | Flavor Profile | Energy Efficiency |

|---|---|---|---|---|---|---|---|

| Oven Roasting | Dry heat causes Maillard reaction and sugar caramelization on the vegetable surface | 180degC - 220degC (356degF - 428degF) | 30 - 60 minutes | Deep, uneven caramelization with crispy edges | Firm exterior, tender interior | Rich, nutty, sweet with roasted notes | Moderate energy use due to long cook times |

| High-Pressure Steam Caramelization | Steam under high pressure accelerates sugar breakdown and caramel formation | 120degC - 140degC (248degF - 284degF) | 10 - 20 minutes | Consistent, moist caramelization with glossy finish | Uniformly tender and juicy texture | Sweeter, milder caramel notes with enhanced natural flavors | Higher energy efficiency due to shorter process time |

Introduction to Vegetable Caramelization Methods

Oven roasting vegetables enhances caramelization by applying dry heat, which concentrates natural sugars and develops a rich, deep flavor through the Maillard reaction. In contrast, high-pressure steam caramelization uses moist heat and elevated pressure to achieve faster caramelization while preserving moisture and nutrient content. Both methods offer unique advantages depending on desired texture and flavor intensity in vegetable preparation.

Understanding Oven Roasting Caramelization

Oven roasting promotes caramelization by applying dry, consistent heat that enhances sugar browning and flavor concentration in vegetables. This method contrasts with high-pressure steam caramelization, which uses moisture and pressure, resulting in a different texture and less pronounced caramelization.

- Dry heat environment - Oven roasting uses dry, radiant heat to trigger the Maillard reaction and caramelize natural sugars on vegetable surfaces.

- Flavor development - The gradual evaporation of moisture during roasting intensifies sweetness and creates complex, caramelized flavors.

- Texture impact - Roasting yields crispy, browned edges and a tender interior, distinct from the softer texture produced by steam caramelization.

The Science Behind High-Pressure Steam Caramelization

High-pressure steam caramelization accelerates the Maillard reaction by increasing temperature and humidity, enhancing sugars' breakdown in vegetables. Unlike oven roasting, this method preserves moisture while intensifying flavor through controlled thermal and enzymatic processes.

- Elevated Temperature and Pressure - High-pressure steam raises internal vegetable temperatures beyond 100degC, speeding up caramelization reactions.

- Moisture Retention - Steam maintains cellular moisture, preventing drying out and promoting uniform caramel formation.

- Enhanced Enzymatic Activity - The combination of heat and pressure activates enzymes that modify sugar molecules, deepening caramel flavors.

Flavor Profiles: Roasting vs Steam Caramelization

Oven roasting enhances vegetable caramelization by promoting Maillard reactions, resulting in rich, complex flavors with a toasted aroma. In contrast, high-pressure steam caramelization yields softer textures and sweeter, more subtle flavor notes due to moist heat exposure.

- Oven Roasting - Develops deep, nutty flavors and crispy edges through dry heat and browning.

- High-Pressure Steam - Preserves vibrant colors and intensifies natural sweetness with rapid cooking under moisture.

- Flavor Intensity - Roasting produces bold, robust tastes while steam offers delicate, mild caramel nuances.

Choosing between roasting and high-pressure steam caramelization depends on the desired texture and flavor complexity in vegetable preparation.

Texture Differences in Roasted and Steam-Caramelized Vegetables

Oven roasting caramelizes vegetables by drawing out moisture and applying dry heat, which creates a crispy, slightly charred exterior and tender interior. This method enhances complex flavors through the Maillard reaction, resulting in a rich, caramelized texture.

High-pressure steam caramelization softens vegetables while infusing them with moisture, producing a uniformly tender texture without the crisp edges typical of roasting. The steam prevents surface drying, preserving vibrant colors and subtle sweetness instead of concentrated caramel notes. Consequently, steam-caramelized vegetables have a smoother, more succulent mouthfeel compared to the firmer, chewier texture of oven-roasted varieties.

Nutrient Retention: Oven Roasting vs High-Pressure Steam

Oven roasting vegetables enhances caramelization by exposing them to dry heat, intensifying flavor while causing moderate nutrient loss, particularly in heat-sensitive vitamins like vitamin C and some B vitamins. This method promotes Maillard reactions and sugar caramelization, resulting in richer taste profiles but with reduced retention of water-soluble nutrients.

High-pressure steam caramelization preserves more nutrients due to the controlled, moist environment, minimizing the degradation of vitamins and antioxidants during cooking. Steam caramelization maintains cellular integrity better than dry heat, leading to higher retention of nutrients such as folate and vitamin C in vegetables.

Equipment and Preparation for Each Method

| Oven Roasting | Uses a conventional or convection oven set to high temperatures (typically 400degF to 450degF) to enhance caramelization through dry heat exposure. Preparation involves coating vegetables lightly in oil and seasoning to promote even browning and flavor development. |

| High-Pressure Steam Caramelization | Requires specialized pressure cookers or autoclaves designed to combine steam and pressure, accelerating sugar breakdown and caramel formation. Vegetables are often prepped by cutting evenly and sometimes blanched, ensuring uniform caramelization under controlled moist heat. |

Time and Energy Efficiency Compared

How do oven roasting and high-pressure steam compare in terms of time and energy efficiency for caramelizing vegetables? Oven roasting typically requires longer cooking times and higher energy consumption due to extended exposure to dry heat. High-pressure steam caramelization significantly reduces cooking time and energy use by accelerating heat transfer and moisture retention.

Best Vegetables for Each Caramelization Technique

Root vegetables like carrots, sweet potatoes, and parsnips excel in oven roasting for caramelization, as the dry heat enhances their natural sugars and produces a rich, deep flavor. Leafy greens and tender vegetables such as Brussels sprouts and asparagus benefit from high-pressure steam caramelization, which preserves moisture while intensifying sweetness without drying out the texture. Each method complements specific vegetable types by optimizing sugar breakdown and flavor concentration suited to their cellular makeup.

Related Important Terms

Dry-Heat Maillard Acceleration

Oven roasting enhances caramelization in vegetables through dry-heat Maillard acceleration, intensifying flavor development and promoting a crisp texture by removing surface moisture. High-pressure steam caramelization, by contrast, retains moisture which inhibits Maillard reactions, resulting in less browning and a softer consistency.

Steam-Infused Sugaring

Steam-infused sugaring leverages high-pressure steam to enhance caramelization by evenly distributing moisture and heat, resulting in vegetables with a glossy, tender texture and intensified natural sweetness. In contrast, oven roasting promotes caramelization through dry heat, developing deeper Maillard reactions and a more complex, browned flavor profile with crisp edges.

Convection Crust Browning

Oven roasting enhances caramelization in vegetables through dry heat that promotes convection crust browning, resulting in a rich, flavorful outer layer with concentrated sugars. In contrast, high-pressure steam caramelization retains moisture, preventing crust formation and limiting the development of the characteristic browned, crispy texture.

Sous-Pressure Caramel Lift

Oven roasting promotes Maillard reaction-driven caramelization by applying dry heat, enhancing the natural sugars in vegetables with a crispy texture and rich flavor. Sous-pressure caramel lift, a high-pressure steam caramelization technique, accelerates sugar breakdown under controlled steam environment, intensifying sweetness and preserving moisture without charring.

Vapor Cascade Caramelization

Oven roasting vegetables promotes caramelization through dry heat that enhances natural sugars via Maillard reactions and vapor cascade caramelization, producing a rich, deep flavor profile. High-pressure steam caramelization accelerates sugar breakdown by maintaining a moist environment and elevated temperature, but vapor cascade caramelization in roasting develops more complex, concentrated caramel notes due to controlled moisture evaporation.

Crisp-Edge Roasting Effect

Oven roasting enhances caramelization by promoting a Maillard reaction that produces a crisp-edge roasting effect, intensifying flavor through direct dry heat exposure. High-pressure steam caramelization, while effective in softening vegetables, lacks the dry heat necessary to create the same crisp edges and complex flavor profiles achieved by oven roasting.

Steam-Burst Surface Searing

Oven roasting enhances caramelization by exposing vegetables to dry heat, promoting Maillard reactions and a deep, crispy surface, while high-pressure steam caramelization uses steam-burst surface searing to rapidly cook and char the exterior, preserving moisture and intensifying natural sugars. Steam-burst surface searing combines high pressure and steam to create a delicate crust without drying out the vegetable interior, offering a unique balance of texture and flavor compared to traditional oven roasting.

Umami-Bloom Steaming

Oven roasting enhances caramelization by using dry heat, which concentrates sugars and creates a rich umami profile through Maillard reactions, while high-pressure steam caramelization leverages Umami-Bloom Steaming to infuse vegetables with moisture and intensified savory compounds. This method preserves texture and elevates flavor depth by accelerating enzymatic processes that release natural glutamates and nucleotides, maximizing umami without the dryness typical of roasting.

Dual-Phase Sweetness Release

Oven roasting vegetables enhances caramelization through Maillard reactions and sugar browning, creating a rich, complex sweetness during a slow, dry-heat process, while high-pressure steam caramelization accelerates sugar breakdown under moist heat, promoting a rapid but less intense dual-phase sweetness release. Combining both methods can optimize flavor by first developing deep caramel notes via oven roasting, then intensifying initial sweetness through high-pressure steam exposure.

Oven Roasting for Caramelization vs High-Pressure Steam Caramelization for vegetables. Infographic

cookingdiff.com

cookingdiff.com