When caramelizing, a granite mortar offers exceptional heat retention and durability, ensuring even caramelization with its dense, rough surface ideal for grinding sugar crystals uniformly. The Japanese suribachi, with its distinctive ridged interior, allows for efficient grinding and mixing but may distribute heat less evenly, potentially affecting the consistency of caramelized sugar. Choosing between the two depends on the desired texture and heat control during the caramelizing process.

Table of Comparison

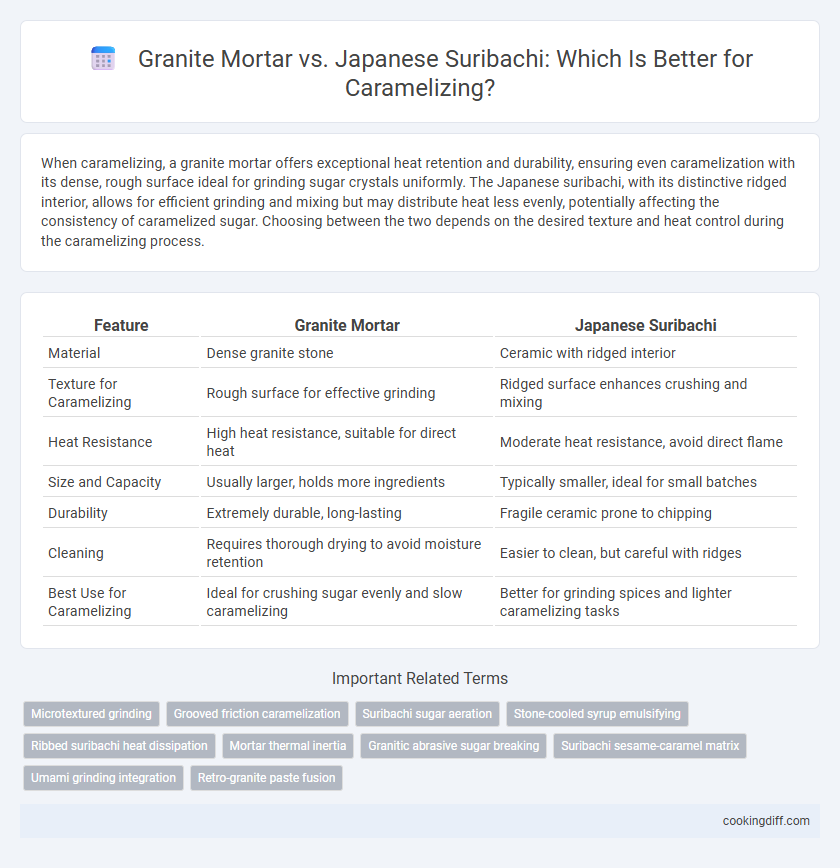

| Feature | Granite Mortar | Japanese Suribachi |

|---|---|---|

| Material | Dense granite stone | Ceramic with ridged interior |

| Texture for Caramelizing | Rough surface for effective grinding | Ridged surface enhances crushing and mixing |

| Heat Resistance | High heat resistance, suitable for direct heat | Moderate heat resistance, avoid direct flame |

| Size and Capacity | Usually larger, holds more ingredients | Typically smaller, ideal for small batches |

| Durability | Extremely durable, long-lasting | Fragile ceramic prone to chipping |

| Cleaning | Requires thorough drying to avoid moisture retention | Easier to clean, but careful with ridges |

| Best Use for Caramelizing | Ideal for crushing sugar evenly and slow caramelizing | Better for grinding spices and lighter caramelizing tasks |

Introduction to Caramelizing Techniques

| Granite Mortar for Caramelizing | Granite mortars offer exceptional durability and even heat distribution, making them ideal for crushing sugar and spices to initiate caramelization. Their rough texture helps break down ingredients efficiently, enhancing the release of natural sugars and flavors essential in caramelizing. They retain heat well, which aids in maintaining consistent temperature during the caramelization process. |

| Japanese Suribachi for Caramelizing | The Japanese suribachi features fine ridges inside the bowl that increase friction, perfect for grinding and mixing sugar and flavor components for caramelizing. Its design allows for controlled crushing and blending, preserving aromatic oils and promoting uniform caramelization. The wooden pestle complements the bowl by reducing heat transfer, preventing premature burning of sugars. |

Overview: Granite Mortar and Japanese Suribachi

Granite mortars and Japanese suribachi both serve as traditional tools for grinding and crushing, with distinct textures affecting their efficiency in caramelizing sugar. Granite mortars offer a coarse, durable surface ideal for robust grinding, while the suribachi's ridged interior allows finer control and a smoother paste.

- Granite Mortar - Made from dense, rough granite, it provides excellent durability and effective grinding for caramelizing coarse sugar.

- Japanese Suribachi - Features fine, spiral grooves that enhance friction, ideal for creating smooth caramel pastes with precise consistency.

- Material Impact - The hardness and texture differences influence the speed and uniformity of sugar caramelization.

Choosing between a granite mortar and a suribachi depends on the desired texture and control during the caramelization process.

Material Composition and Heat Retention

The granite mortar is made from dense, coarse-grained igneous rock that offers excellent heat retention, allowing for even caramelizing without rapid cooling. In contrast, the Japanese suribachi, crafted from ceramic with an unglazed, ridged interior, provides less heat retention but superior grinding texture for caramelizing ingredients. Granite's thermal mass supports sustained heat levels, while suribachi excels in abrasion but requires quicker processing to prevent heat loss during caramelization.

Texture and Surface Impact on Caramelization

Granite mortars have a coarse, rough texture that facilitates even abrasion, promoting uniform caramelization by allowing consistent heat distribution and better sugar breakdown. Japanese suribachi, with its fine ridged surface, creates a unique friction that gently crushes ingredients, resulting in a delicate caramelization process ideal for subtle flavors. The contrasted surfaces directly impact caramelization speed and texture, with granite offering robust, intense results and suribachi providing controlled, refined caramel development.

Ease of Grinding Sugar and Ingredients

The Japanese suribachi features ridged interiors that enhance friction, making it easier to grind sugar and other ingredients into a fine, consistent texture necessary for caramelizing. In contrast, the smooth surface of a granite mortar may require more effort and time to achieve the same degree of grinding due to reduced natural abrasion.

Suribachi's lightweight design offers more control and efficiency during the grinding process, which helps prevent sugar from clumping and burning prematurely. Granite mortars, while durable and aesthetically pleasing, can be less practical for delicate tasks like caramelizing sugar because they lack textured interiors that facilitate quick and even grinding.

Versatility in Caramelizing Applications

The granite mortar excels in evenly distributing heat and pressure, making it ideal for caramelizing tougher ingredients and achieving a consistent texture. Its heavy, durable surface allows for effective grinding and mashing, enhancing the caramelization process by breaking down sugars thoroughly.

The Japanese suribachi, with its ridged interior, provides superior friction, facilitating faster caramelization of softer ingredients like nuts and seeds. Its lightweight design offers greater maneuverability, making it versatile for small-batch caramelizing tasks and delicate flavor extraction.

Cleaning and Maintenance Considerations

Which is easier to clean after caramelizing, a granite mortar or a Japanese suribachi? Granite mortar's non-porous surface resists sticky caramel residue, making it simpler to wash with warm water and mild detergent. Japanese suribachi's ridged ceramic interior can trap caramel, requiring more thorough scrubbing and soaking to maintain cleanliness.

Flavor Influence: Granite vs Suribachi

Granite mortars provide a neutral surface that preserves the pure caramel flavor during crushing, while Japanese suribachi bowls have a textured interior that subtly enhances the depth and complexity of caramelized ingredients. The choice between granite and suribachi impacts flavor extraction and texture due to their material properties and surface finishes.

- Granite mortar's smooth surface - Prevents flavor alteration, maintaining the natural sweetness and bitterness balance in caramel.

- Japanese suribachi's textured grooves - Increase friction to release essential oils and intensify caramelized notes.

- Material porosity - Granite is less porous, reducing absorption of flavors, whereas suribachi may absorb some oils, subtly influencing taste.

User Experience: Traditional vs Modern Methods

Granite mortars provide a sturdy, weighty base ideal for slow, controlled caramelizing, enhancing texture through traditional grinding motions. Japanese suribachi surfaces, with their textured interiors, enable quicker caramelization by increasing friction, offering a more modern and efficient user experience.

- Granite mortar durability - Heavyweight design ensures stability during extended caramelizing sessions, supporting gradual ingredient transformation.

- Suribachi friction efficiency - Grooved ceramic patterns facilitate faster breakdown of sugars, reducing preparation time.

- User comfort - Both options promote tactile engagement, but suribachi's lighter weight improves maneuverability in modern kitchens.

Related Important Terms

Microtextured grinding

Granite mortars offer a coarse, natural texture ideal for slowly releasing flavors while caramelizing, whereas Japanese suribachi feature a fine, microtextured interior perfect for finely grinding ingredients to evenly distribute sugars and achieve smooth caramelization. The suribachi's precise microtexture facilitates better control over ingredient breakdown, enhancing the caramel's flavor complexity and consistency compared to the broader abrasive surface of granite mortars.

Grooved friction caramelization

Japanese suribachi, with its distinctive grooved interior, provides superior friction for caramelizing sugar compared to the smooth surface of a granite mortar, enhancing the melting and browning process. The textured grooves in the suribachi increase surface contact and abrasion, allowing for more even caramelization and preventing rapid crystallization.

Suribachi sugar aeration

Japanese suribachi excels in caramelizing by effectively aerating sugar through its textured grooves, which enhance heat distribution and promote even caramel formation. Unlike a smooth granite mortar, the suribachi's design allows better airflow and sugar granule separation, resulting in a richer, more consistent caramel texture.

Stone-cooled syrup emulsifying

Granite mortars maintain consistent cooling during caramelizing, allowing syrup emulsions to stabilize without overheating, which prevents crystallization and enhances texture. Japanese suribachi's ridged interior aids in integrating ingredients but retains more heat, making it less effective at stone-cooling syrup emulsions for delicate caramelizing processes.

Ribbed suribachi heat dissipation

The Japanese suribachi's ribbed interior enhances heat dissipation during caramelizing, preventing hot spots and allowing for more even melting and browning of sugars compared to a smooth granite mortar. This textured surface aids in better control of caramelization temperature, resulting in a consistent, richer flavor profile.

Mortar thermal inertia

Granite mortar offers superior thermal inertia compared to the Japanese suribachi, maintaining consistent heat essential for even caramelizing without sudden temperature drops. This thermal stability in granite ensures precise control over sugar melting and browning, resulting in a richer caramel flavor and texture.

Granitic abrasive sugar breaking

Granite mortar offers a coarse, abrasive texture ideal for breaking down sugar crystals during caramelizing, enhancing the caramel's smoothness and depth of flavor. Unlike the finer grooves of a Japanese suribachi, the granitic surface provides a more effective abrasive action that facilitates thorough sugar granulation and even caramelization.

Suribachi sesame-caramel matrix

The Japanese suribachi excels in caramelizing by creating a unique sesame-caramel matrix, where its ridged surface facilitates even grinding and integration of sesame seeds with caramelized sugar, enhancing flavor and texture complexity. Granite mortar, though durable, lacks the fine-textured grip of suribachi, resulting in less efficient blending and a less cohesive caramelized sesame mixture.

Umami grinding integration

Granite mortars provide a coarse, durable surface ideal for breaking down ingredients, enhancing the release of natural sugars and deepening caramelization with robust umami flavors. Japanese suribachi, featuring fine ridges, allows for smoother grinding that integrates umami compounds evenly, promoting a balanced caramelized texture with subtle flavor complexity.

Granite mortar vs Japanese suribachi for caramelizing. Infographic

cookingdiff.com

cookingdiff.com