Nonstick pans provide an easy-release surface that prevents sugar from sticking and burning during caramelizing, making cleanup straightforward and reducing the risk of uneven cooking. Carbon steel skillets offer superior heat retention and distribution, essential for achieving consistent caramelization and developing deeper flavors, though they require proper seasoning and maintenance to prevent sticking. Choosing between the two depends on whether ease of use or enhanced flavor development is the priority in the caramelizing process.

Table of Comparison

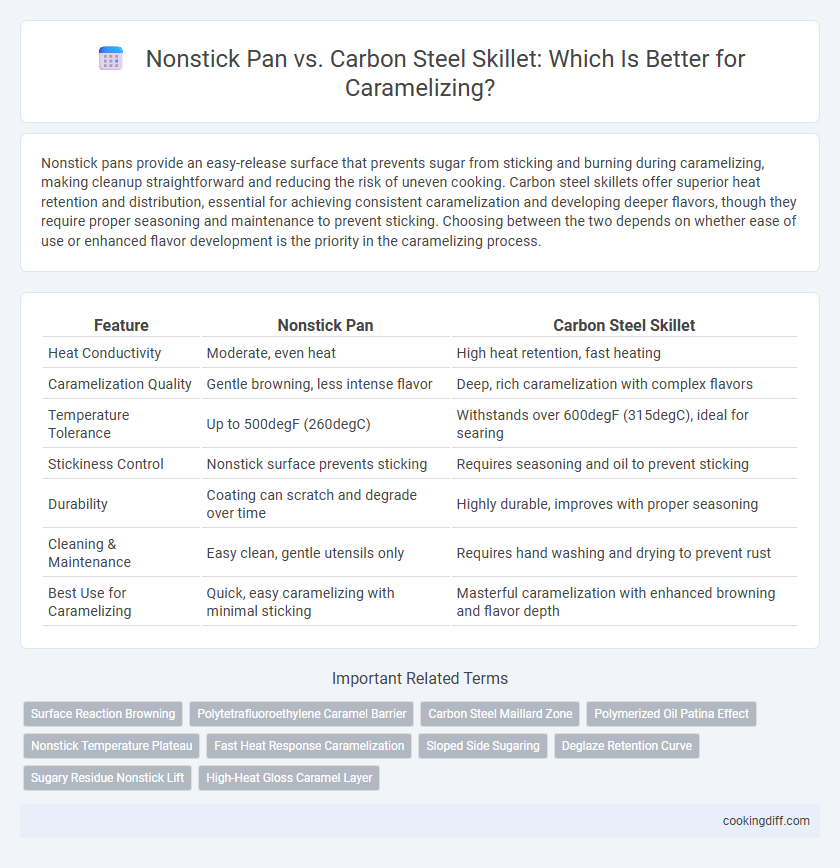

| Feature | Nonstick Pan | Carbon Steel Skillet |

|---|---|---|

| Heat Conductivity | Moderate, even heat | High heat retention, fast heating |

| Caramelization Quality | Gentle browning, less intense flavor | Deep, rich caramelization with complex flavors |

| Temperature Tolerance | Up to 500degF (260degC) | Withstands over 600degF (315degC), ideal for searing |

| Stickiness Control | Nonstick surface prevents sticking | Requires seasoning and oil to prevent sticking |

| Durability | Coating can scratch and degrade over time | Highly durable, improves with proper seasoning |

| Cleaning & Maintenance | Easy clean, gentle utensils only | Requires hand washing and drying to prevent rust |

| Best Use for Caramelizing | Quick, easy caramelizing with minimal sticking | Masterful caramelization with enhanced browning and flavor depth |

Introduction: Choosing the Right Pan for Caramelizing

Choosing the right pan is crucial for achieving perfect caramelization, impacting both heat distribution and flavor development. Nonstick pans offer ease of use and cleanup, while carbon steel skillets provide superior heat retention and enhanced browning capabilities.

- Nonstick pans offer even heat distribution - Their coated surface prevents sugar from sticking, making caramel easier to manage.

- Carbon steel skillets excel at heat retention - They maintain consistent high temperatures needed for deep caramelization.

- Pan material affects flavor and texture - Carbon steel can develop a natural seasoning that enhances caramel flavor over time.

Nonstick Pan Overview: Features and Benefits

Nonstick pans offer an even heat distribution that prevents food from sticking, making them ideal for delicate caramelizing tasks. Their smooth surface requires less oil, ensuring a cleaner caramelization process with consistent browning. Easy cleanup and reduced risk of burning sugar make nonstick pans a preferred option over carbon steel skillets for beginners and quick caramel recipes.

Carbon Steel Skillet Overview: Features and Advantages

Why is a carbon steel skillet preferred over a nonstick pan for caramelizing? Carbon steel skillets offer superior heat retention and even distribution, essential for achieving the perfect caramelization without burning. Their ability to develop a natural nonstick patina over time enhances flavor and improves cooking efficiency compared to coated nonstick surfaces.

Heat Distribution: Nonstick vs Carbon Steel

Nonstick pans offer even heat distribution with a smooth surface that prevents sugar from sticking during caramelizing, ensuring consistent browning. Their coated surface reduces hot spots, allowing delicate control over the caramelization process.

Carbon steel skillets provide superior heat retention and excellent responsiveness to temperature changes, which is critical for precise caramelization control. However, their uneven heat distribution can cause hotspots that require careful monitoring to avoid burning the caramel.

Caramelization Results: Which Pan Delivers Better Browning?

Carbon steel skillets deliver superior caramelization results due to their excellent heat retention and even heat distribution, which promotes deeper browning and richer flavor development. Nonstick pans, while convenient for easy release, typically produce less intense browning since they heat less efficiently and often operate at lower temperatures. For achieving optimal caramelization with a beautifully crisp crust, a seasoned carbon steel skillet outperforms nonstick alternatives.

Temperature Control: Performance Differences

Nonstick pans provide more consistent temperature control, preventing hot spots during caramelizing and reducing the risk of burning sugar. Carbon steel skillets heat up faster and retain heat longer, but require more skill to manage temperature fluctuations effectively.

Carbon steel skillets excel in high-heat applications, allowing for better browning and deeper flavor development when caramelizing. Their responsiveness to heat changes demands attentive temperature monitoring to avoid scorching. Nonstick pans offer ease of use with even heat distribution, making them ideal for beginners seeking reliable caramelization results.

Maintenance and Durability: Nonstick vs Carbon Steel

Nonstick pans require gentle cleaning and careful use of utensils to maintain their coating, which can wear off over time. Carbon steel skillets demand regular seasoning and proper drying to prevent rust, but they develop a natural nonstick surface with use.

- Maintenance - Nonstick pans should be hand-washed with mild detergents and avoid abrasive sponges to preserve the coating.

- Durability - Carbon steel skillets are highly durable and can last a lifetime if properly maintained through seasoning and drying.

- Performance over Time - Carbon steel improves with seasoning, enhancing its nonstick quality, while nonstick pans gradually lose effectiveness as the coating degrades.

Ease of Use: Handling and Versatility

Nonstick pans offer effortless handling and are highly versatile for caramelizing delicate ingredients due to their smooth surface, preventing sticking and burning. Carbon steel skillets require seasoning and careful temperature control but provide superior heat retention and browning capabilities.

- Nonstick pans excel in ease of cleaning - Their coated surface allows quick removal of caramel residues without abrasive scrubbing.

- Carbon steel skillets improve with seasoning - Over time, they develop a natural nonstick patina enhancing performance and flavor complexity.

- Versatility varies by material - Nonstick is ideal for low to medium heat caramelization, while carbon steel tolerates high heat for deeper caramelization.

Choosing between these pans depends on user preference for maintenance and desired caramelization results.

Cleaning and Care: What to Expect

Nonstick pans offer easier cleaning after caramelizing due to their smooth, coated surface that prevents food from sticking and requires minimal scrubbing. However, their coating can degrade over time with abrasive cleaning or high heat exposure, necessitating gentle care and hand washing.

Carbon steel skillets develop a natural nonstick patina with use, which enhances flavor but demands regular seasoning and proper drying to prevent rust. Cleaning typically involves hot water and a soft brush without soap, as harsh detergents can strip the seasoning layer, requiring more maintenance than nonstick alternatives.

Related Important Terms

Surface Reaction Browning

Nonstick pans provide even heat distribution and prevent sticking, making them ideal for delicate caramelization with minimal risk of burning, while carbon steel skillets excel in high-heat scenarios, promoting intense surface reaction browning due to their ability to develop a natural seasoning layer that enhances flavor complexity. Carbon steel's superior heat retention and responsiveness enable the Maillard reaction to occur more rapidly, producing deeper, richer caramelization compared to the more controlled but less reactive surface of nonstick cookware.

Polytetrafluoroethylene Caramel Barrier

Polytetrafluoroethylene (PTFE) coating in nonstick pans creates an effective caramel barrier that prevents sugar from sticking and burning during caramelizing, allowing for smoother cleanup and consistent texture. In contrast, carbon steel skillets lack this PTFE layer, often resulting in more sticking and potential for uneven caramelization but develop a natural seasoning that can enhance flavor over time.

Carbon Steel Maillard Zone

Carbon steel skillets excel in caramelizing due to their superior heat conductivity and ability to reach the Maillard zone evenly, enhancing complex flavor development and deep browning. Nonstick pans prevent sticking but often lack the high-heat tolerance necessary for optimal Maillard reactions, resulting in less intense caramelization.

Polymerized Oil Patina Effect

Carbon steel skillets develop a polymerized oil patina that enhances caramelization by providing a naturally nonstick surface with superior heat retention and even browning compared to nonstick pans. Nonstick pans lack this seasoning layer, which limits their ability to achieve complex caramelized flavors and textures essential for professional-quality cooking.

Nonstick Temperature Plateau

Nonstick pans maintain a temperature plateau ideal for caramelizing because their low thermal mass and non-reactive coating allow precise temperature control and prevent burning. Carbon steel skillets heat faster but lack this temperature stability, increasing the risk of uneven caramelization and scorching.

Fast Heat Response Caramelization

Carbon steel skillets offer superior fast heat response, ensuring even caramelization and precise temperature control essential for developing rich, deep flavors in sugars. Nonstick pans heat more slowly and less evenly, which can result in inconsistent caramelization and less optimal browning.

Sloped Side Sugaring

A carbon steel skillet with sloped sides enhances caramelization by allowing sugars to collect and brown evenly without burning, unlike many nonstick pans where sugars can pool and burn due to flatter edges. The excellent heat retention and responsiveness of carbon steel promote superior Maillard reactions, creating deeper, richer caramel flavors compared to the more heat-sensitive surface of nonstick cookware.

Deglaze Retention Curve

Carbon steel skillets offer superior heat retention and a sharper deglaze retention curve compared to nonstick pans, allowing for more efficient caramelization and flavorful fond development. Nonstick pans, while preventing sticking, often have uneven heat distribution that weakens fond formation and reduces the intensity of deglazed sauces.

Sugary Residue Nonstick Lift

Carbon steel skillets excel at caramelizing due to their ability to develop a natural patina that prevents sugary residue from sticking, allowing for effortless nonstick lift of delicate caramelized sugars. Nonstick pans, while initially effective at preventing sticking, can degrade at high heat and may leave a less pronounced fond, impacting the complex flavor development in caramelization.

Nonstick pan vs carbon steel skillet for caramelizing. Infographic

cookingdiff.com

cookingdiff.com