Dry caramelization involves heating sugar alone until it melts and turns golden brown, creating a deep, rich flavor ideal for syrups with intense caramel notes. Wet caramelization, on the other hand, mixes sugar with water before heating, allowing for more control over the cooking process and producing a smoother, more translucent syrup. Both methods impact the syrup's texture and taste, with dry caramelization offering a robust profile and wet caramelization providing a delicate balance suitable for various applications.

Table of Comparison

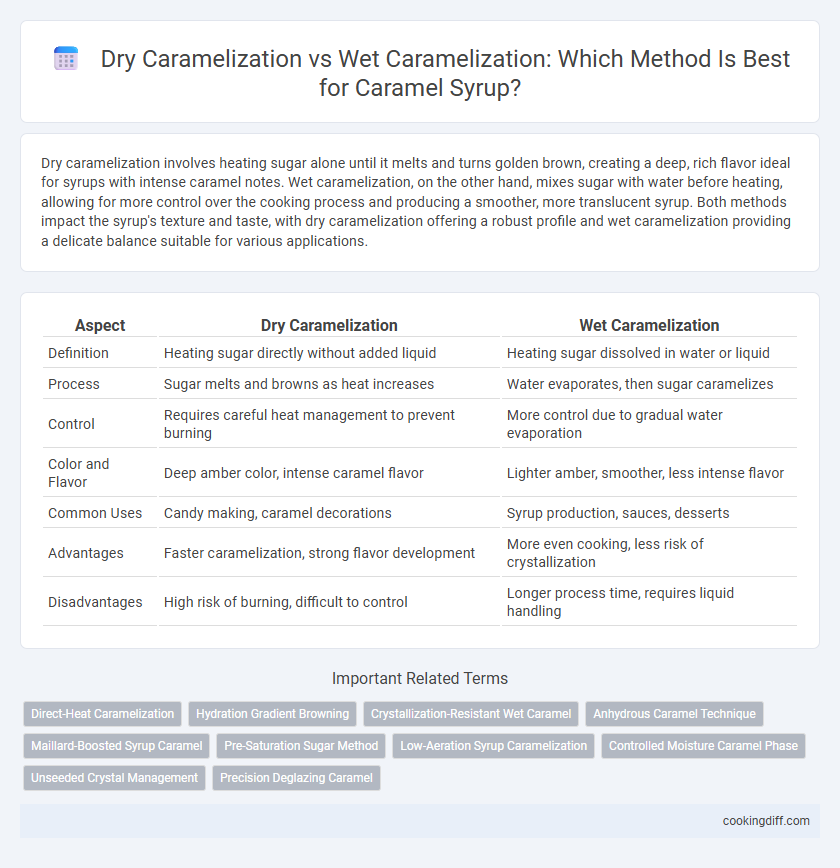

| Aspect | Dry Caramelization | Wet Caramelization |

|---|---|---|

| Definition | Heating sugar directly without added liquid | Heating sugar dissolved in water or liquid |

| Process | Sugar melts and browns as heat increases | Water evaporates, then sugar caramelizes |

| Control | Requires careful heat management to prevent burning | More control due to gradual water evaporation |

| Color and Flavor | Deep amber color, intense caramel flavor | Lighter amber, smoother, less intense flavor |

| Common Uses | Candy making, caramel decorations | Syrup production, sauces, desserts |

| Advantages | Faster caramelization, strong flavor development | More even cooking, less risk of crystallization |

| Disadvantages | High risk of burning, difficult to control | Longer process time, requires liquid handling |

Introduction to Caramelization Methods

| Dry Caramelization | Involves heating sugar alone until it melts and turns golden brown, producing a rich, intense flavor without added moisture. |

| Wet Caramelization | Begins by dissolving sugar in water before heating, allowing controlled temperature rise and smoother caramel suitable for syrups. |

| Usage in Syrup | Wet caramelization is preferred for syrups due to better control over texture and prevention of crystallization, whereas dry caramelization offers deeper flavor but requires careful timing to avoid burning. |

What is Dry Caramelization?

Dry caramelization involves heating sugar alone without any added water, causing it to melt and undergo complex chemical changes. This method produces a rich, deep amber syrup with a stronger, more intense flavor compared to wet caramelization.

- Process - Sugar is directly heated in a pan until it melts and browns without dilution.

- Flavor Profile - Results in a robust, slightly bitter taste that enhances depth in syrups.

- Control - Requires careful temperature management to prevent burning and achieve desired caramel color.

What is Wet Caramelization?

Wet caramelization involves dissolving sugar in water before heating, which allows for a more controlled and even caramel development. This method reduces the risk of burning by maintaining moisture until the sugar begins to caramelize, making it ideal for syrups and sauces.

In contrast to dry caramelization, wet caramelization produces a smoother texture and more consistent color in syrup preparation. The added water helps regulate the temperature, resulting in a rich, glossy caramel perfect for desserts and beverages.

Key Differences between Dry and Wet Caramelization

What are the key differences between dry and wet caramelization when making syrup? Dry caramelization involves heating sugar directly until it melts and browns, creating a more intense, nutty flavor, while wet caramelization dissolves sugar in water before heating, allowing for better control and a smoother, milder syrup consistency. Dry caramelization requires careful temperature monitoring to prevent burning, whereas wet caramelization reduces the risk of crystallization due to the added water.

Ingredients Needed for Dry vs Wet Caramelization

Dry caramelization requires only granulated sugar heated directly, allowing it to melt and brown without added liquids. This method depends solely on the sugar's natural properties to achieve caramelization.

Wet caramelization involves combining sugar with water before heating, creating a syrup that caramelizes as the water evaporates. This approach requires precise measurement of water to control the consistency and prevent crystallization.

Step-by-Step Guide: Making Syrup with Dry Caramelization

Start by heating granulated sugar evenly in a heavy-bottomed pan over medium heat without adding water, allowing it to melt and transform into a rich amber liquid. Stir gently only when the edges begin to liquefy to prevent crystallization and achieve a smooth caramel base. Once the desired color is reached, carefully add warm liquid such as water or cream to the caramel while stirring to create a glossy syrup perfect for desserts.

Step-by-Step Guide: Making Syrup with Wet Caramelization

Wet caramelization involves dissolving sugar in water before heating, allowing for a controlled and even caramelization ideal for syrup making. This method prevents burning and ensures a smooth, glossy syrup consistency.

- Combine sugar and water - Dissolve sugar completely in cold water to prepare for even caramelization.

- Heat gently - Slowly bring the mixture to a boil to allow gradual caramel formation without scorching.

- Monitor color changes - Watch the syrup closely as it transitions through amber hues to achieve desired flavor and color.

Wet caramelization produces a balanced, rich syrup perfect for culinary applications requiring smooth texture and flavor.

Pros and Cons: Dry Caramelization for Syrup

Dry caramelization involves heating sugar directly without water, resulting in a more intense and complex flavor ideal for rich syrups. This method requires close attention to prevent burning, which can produce bitter flavors and ruined batches.

- Rich Flavor Development - Dry caramelization enhances the syrup's taste with deeper, more robust caramel notes.

- Risk of Burning - High temperatures and lack of water increase the likelihood of scorching the sugar if not carefully monitored.

- Quick Process - Dry caramelization typically takes less time than wet methods, making it efficient for experienced cooks.

Pros and Cons: Wet Caramelization for Syrup

Wet caramelization for syrup involves dissolving sugar in water before heating, which allows for more controlled and even caramel formation. This method reduces the risk of burning compared to dry caramelization, but it requires careful boiling to achieve the desired syrup consistency.

Wet caramelization produces a smoother, less bitter syrup ideal for delicate desserts and beverages. The main drawback is the longer cooking time needed to evaporate excess water, which can sometimes dilute flavors if not carefully managed. Precise temperature control is essential to prevent crystallization and ensure a glossy, uniform syrup texture.

Related Important Terms

Direct-Heat Caramelization

Direct-heat caramelization involves applying high heat directly to sugar, promoting dry caramelization that produces a rich, complex flavor and deep amber color ideal for syrups. In contrast, wet caramelization introduces water to dissolve sugar, requiring longer cooking times and resulting in a milder taste and lighter hue.

Hydration Gradient Browning

Dry caramelization involves heating sugar without added water, causing a rapid hydration gradient browning as the sugar molecules break down and polymerize directly on the surface. Wet caramelization for syrup introduces water, which moderates the hydration gradient and results in a more uniform browning process due to gradual evaporation and sugar concentration.

Crystallization-Resistant Wet Caramel

Dry caramelization involves heating sugar alone until it melts and browns, while wet caramelization uses sugar dissolved in water to control the cooking process and prevent uneven burning. Wet caramel, especially when formulated to be crystallization-resistant by adding invert sugars or acids like lemon juice, produces a smoother syrup ideal for consistent texture and stability in confectionery applications.

Anhydrous Caramel Technique

Dry caramelization involves heating sugar without any water, allowing anhydrous caramel formation that yields a rich, deep amber syrup with intense flavor complexity. Wet caramelization starts with sugar dissolved in water, resulting in a more controlled, gradual caramel with less risk of burning but typically lighter color and flavor intensity.

Maillard-Boosted Syrup Caramel

Dry caramelization involves heating sugar alone until it melts and browns, producing a deep, rich flavor and vibrant amber color ideal for syrups, while wet caramelization combines sugar with water to control heat and prevent burning. Maillard-boosted syrup caramel enhances complexity by incorporating amino acids from proteins, accelerating browning reactions and resulting in a more intense, savory-sweet flavor profile.

Pre-Saturation Sugar Method

Dry caramelization involves heating sugar directly until it melts and darkens, creating a rich, deep flavor ideal for syrups with intense caramel notes. The Pre-Saturation Sugar Method, a wet caramelization technique, dissolves sugar in water before heating, allowing more control over caramel color and preventing premature burning, resulting in a smoother syrup consistency.

Low-Aeration Syrup Caramelization

Dry caramelization involves heating sugar directly until it melts and browns, creating deep, complex flavors ideal for low-aeration syrups, while wet caramelization dissolves sugar in water before heating, producing cleaner, lighter caramel notes. Low-aeration syrup caramelization benefits from dry methods as reduced oxygen exposure limits oxidation, enhancing flavor stability and achieving a richer amber color.

Controlled Moisture Caramel Phase

Dry caramelization involves heating sugar without added water, reaching high temperatures that produce a deep amber color and rich flavor but require precise temperature control to avoid burning. Wet caramelization, involving sugar dissolved in water, allows better control over moisture content during the caramel phase, resulting in a smoother syrup texture and more consistent caramel color development.

Unseeded Crystal Management

Dry caramelization involves heating sugar directly until it melts and browns, requiring precise temperature control to prevent premature crystallization, while wet caramelization dissolves sugar in water, allowing better management of unseeded crystal formation through careful stirring and temperature regulation. Unseeded crystal management in wet caramelization relies on controlling moisture content and avoiding agitation once the syrup reaches the soft ball stage to ensure smooth, clear syrup without graininess.

Dry Caramelization vs Wet Caramelization for Syrup Infographic

cookingdiff.com

cookingdiff.com