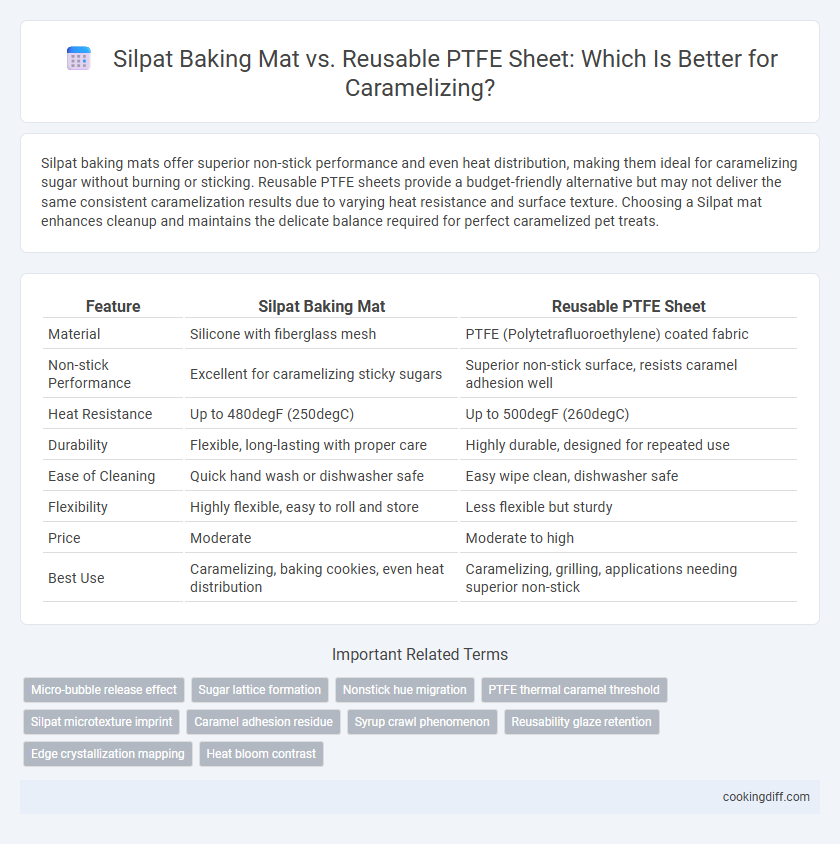

Silpat baking mats offer superior non-stick performance and even heat distribution, making them ideal for caramelizing sugar without burning or sticking. Reusable PTFE sheets provide a budget-friendly alternative but may not deliver the same consistent caramelization results due to varying heat resistance and surface texture. Choosing a Silpat mat enhances cleanup and maintains the delicate balance required for perfect caramelized pet treats.

Table of Comparison

| Feature | Silpat Baking Mat | Reusable PTFE Sheet |

|---|---|---|

| Material | Silicone with fiberglass mesh | PTFE (Polytetrafluoroethylene) coated fabric |

| Non-stick Performance | Excellent for caramelizing sticky sugars | Superior non-stick surface, resists caramel adhesion well |

| Heat Resistance | Up to 480degF (250degC) | Up to 500degF (260degC) |

| Durability | Flexible, long-lasting with proper care | Highly durable, designed for repeated use |

| Ease of Cleaning | Quick hand wash or dishwasher safe | Easy wipe clean, dishwasher safe |

| Flexibility | Highly flexible, easy to roll and store | Less flexible but sturdy |

| Price | Moderate | Moderate to high |

| Best Use | Caramelizing, baking cookies, even heat distribution | Caramelizing, grilling, applications needing superior non-stick |

Introduction to Caramelizing: The Importance of Bakeware

Caramelizing requires precise heat distribution and a non-stick surface to achieve perfect browning without burning. The choice of bakeware significantly influences the texture and flavor development during the caramelization process.

- Silpat Baking Mat - Made of silicone and fiberglass, it provides even heat distribution and a reliable non-stick surface ideal for caramelizing sugars.

- Reusable PTFE Sheet - Coated with polytetrafluoroethylene, it offers excellent non-stick properties but may have uneven heat transfer compared to Silpat.

- Durability and Maintenance - Silpat mats generally withstand repeated caramelizing sessions without degradation, whereas PTFE sheets require careful handling to preserve their coating.

Selecting the appropriate bakeware improves caramelization results by enhancing heat control and preventing sugar adhesion.

What is a Silpat Baking Mat?

The Silpat baking mat is a non-stick, heat-resistant silicone mat designed to provide an even surface for baking and caramelizing without the need for oils. It is favored for its durability and ease of cleaning compared to traditional reusable PTFE sheets.

- Material Composition - Made from food-grade silicone bonded to fiberglass mesh, ensuring excellent heat distribution and stability.

- Non-Stick Performance - Offers superior non-stick properties that prevent caramelized sugars from sticking and burning during cooking.

- Temperature Tolerance - Can withstand temperatures up to 480degF (250degC), making it ideal for high-heat caramelizing tasks.

Exploring Reusable PTFE Sheets: Features and Composition

| Material Composition | Reusable PTFE sheets are made from polytetrafluoroethylene coated fiberglass, ensuring non-stick surfaces ideal for caramelizing sugars evenly without burning. |

| Heat Resistance | These sheets withstand high temperatures up to 260degC (500degF), enabling consistent caramelization while maintaining durability and flexibility. |

| Non-Toxic and Food Safe | PTFE sheets are FDA-approved for food contact, preventing chemical leaching and ensuring safety during baking and caramelizing processes. |

| Reusability and Cleaning | Unlike traditional parchment paper, PTFE sheets can be washed and reused multiple times, providing an eco-friendly and cost-effective alternative for caramelizing. |

Heat Distribution: Silpat vs PTFE Sheet for Caramelizing

Silpat baking mats provide superior heat distribution for caramelizing compared to reusable PTFE sheets, promoting even browning and reducing hot spots. PTFE sheets tend to have less uniform heat transfer, which can lead to inconsistent caramelization results.

- Silpat ensures consistent heat flow - Its fiberglass mesh embedded in silicone evenly distributes heat for flawless caramelizing.

- PTFE sheets offer less heat uniformity - The smooth surface sometimes causes uneven temperature zones, affecting caramel color.

- Silpat withstands higher temperatures - It maintains structural stability at up to 480degF, ideal for precise caramelization processes.

Non-Stick Performance Compared: Silpat and PTFE Sheets

Which offers better non-stick performance for caramelizing, Silpat baking mats or reusable PTFE sheets? Silpat mats provide superior heat distribution and prevent sugar from sticking due to their silicone coating, making caramel removal easier. Reusable PTFE sheets also offer non-stick benefits but may not evenly distribute heat, potentially causing uneven caramelization.

Ease of Cleaning After Caramelizing: Silpat Versus PTFE

Silpat baking mats are made from silicone and fiberglass, offering a non-stick surface that simplifies cleaning after caramelizing by preventing sugar from bonding tightly. Reusable PTFE sheets, coated with polytetrafluoroethylene, also resist caramel adhesion but often require more thorough scrubbing to remove stubborn residue.

Silpat mats can be easily wiped clean with warm soapy water, making them highly user-friendly for caramelizing tasks. In contrast, PTFE sheets are prone to discoloration and may retain oily residues, demanding more intensive cleaning efforts. Both options are durable, but Silpat's flexibility and stain resistance enhance overall ease of maintenance in caramel preparation.

Reusability and Durability: Which Lasts Longer?

The Silpat baking mat, made from high-quality silicone, offers exceptional reusability, often lasting thousands of uses without degrading, making it a top choice for caramelizing. Reusable PTFE sheets, while also durable and non-stick, tend to wear out faster due to lower heat resistance and increased susceptibility to scratches. For long-term caramelizing tasks, the Silpat mat provides superior durability and consistent performance over time compared to most reusable PTFE sheets.

Food Safety: Silpat Mat vs PTFE Sheet in High-Heat Cooking

Silpat baking mats are made from food-grade silicone and fiberglass mesh, offering excellent heat resistance up to 480degF (250degC) without releasing harmful chemicals. Reusable PTFE sheets, while non-stick and heat-resistant, can start to degrade and emit toxic fumes when exposed to temperatures above 500degF (260degC), posing potential food safety risks during caramelizing.

Silpat mats provide a safer option for high-heat cooking processes like caramelizing due to their chemical stability and FDA approval for food contact. PTFE sheets require careful temperature control to avoid overheating, making Silpat mats more reliable for consistent, safe caramelization results.

Cost-Effectiveness: Investment Comparison for Home Cooks

Silpat baking mats typically cost more upfront but offer exceptional durability and non-stick performance, making them a cost-effective choice for frequent caramelizing. Reusable PTFE sheets are less expensive initially but may require more frequent replacement due to wear and reduced non-stick quality over time. Home cooks prioritizing long-term investment and consistent results often find Silpat mats to provide better overall value despite the higher initial price.

Related Important Terms

Micro-bubble release effect

Silpat baking mats offer superior micro-bubble release during caramelizing due to their advanced silicone composition, which prevents sticking and promotes even heat distribution. Reusable PTFE sheets provide a non-stick surface but lack the micro-bubble release benefits that enhance texture and browning in caramelized foods.

Sugar lattice formation

Silpat baking mats provide a non-stick, heat-resistant surface ideal for even caramelization and easy release of delicate sugar lattices, preventing unwanted sticking and burning. Reusable PTFE sheets also offer excellent non-stick properties and temperature durability, but Silpat's textured surface enhances airflow beneath the caramel, promoting more consistent lattice browning and crispness.

Nonstick hue migration

Silpat baking mats feature premium nonstick silicone surfaces that prevent hue migration during caramelizing, maintaining the appearance and quality of both the caramel and the mat itself. Reusable PTFE sheets, while nonstick, are more prone to discoloration and hue migration over time when exposed to high heat and caramel sugars, potentially affecting the final product's color and texture.

PTFE thermal caramel threshold

Silpat baking mats typically withstand temperatures up to 480degF (250degC), making them suitable for most caramelizing processes, whereas reusable PTFE sheets often have a higher thermal threshold around 500degF (260degC), allowing for more precise caramelization without burning. The superior heat resistance of PTFE sheets ensures consistent non-stick performance and prevents caramel from adhering or burning at elevated temperatures.

Silpat microtexture imprint

Silpat baking mats feature a unique microtexture that promotes even caramelization by allowing precise heat distribution and preventing sticking without additional oils. Reusable PTFE sheets, while non-stick and heat-resistant, lack this intricate microtexture, resulting in less uniform caramel browning and texture control during the cooking process.

Caramel adhesion residue

Silpat baking mats provide a non-stick surface that significantly reduces caramel adhesion residue compared to reusable PTFE sheets, which can sometimes accumulate sticky buildup after repeated use. The textured silicone surface of Silpat mats ensures easier cleanup and consistent caramel release, enhancing overall baking efficiency.

Syrup crawl phenomenon

Silpat baking mats provide a superior non-stick surface that minimizes syrup crawl during caramelizing by maintaining consistent heat distribution and preventing syrup from sliding off the edges. In contrast, reusable PTFE sheets can exhibit more frequent syrup crawl due to their less precise texture and uneven heat retention, which causes caramelized syrup to spread uncontrollably.

Reusability glaze retention

Silpat baking mats offer superior glaze retention during caramelizing thanks to their high-quality silicone surface, ensuring consistent browning and reduced sticking for multiple uses. Reusable PTFE sheets also provide non-stick benefits but often exhibit reduced glaze adherence over time, impacting caramelization quality and reusability.

Edge crystallization mapping

Silpat baking mats provide a non-stick surface that promotes even heat distribution, minimizing edge crystallization during caramelizing compared to reusable PTFE sheets, which often exhibit inconsistent surface textures leading to uneven caramel edges. Advanced edge crystallization mapping reveals that Silpat mats yield smoother caramel contours and reduced sugar crystal buildup, enhancing both texture and presentation.

Silpat baking mat vs reusable PTFE sheet for caramelizing. Infographic

cookingdiff.com

cookingdiff.com