Caramelizing sugar involves heating sucrose until it melts and browns, producing complex flavors and a rich amber color essential for traditional candy making. Maltose caramelization, on the other hand, requires higher temperatures and results in a different flavor profile with less bitterness and more subtle, malty notes ideal for specific confections. Understanding the differences between caramelizing sucrose and maltose is crucial for controlling texture, sweetness, and color in various candy recipes.

Table of Comparison

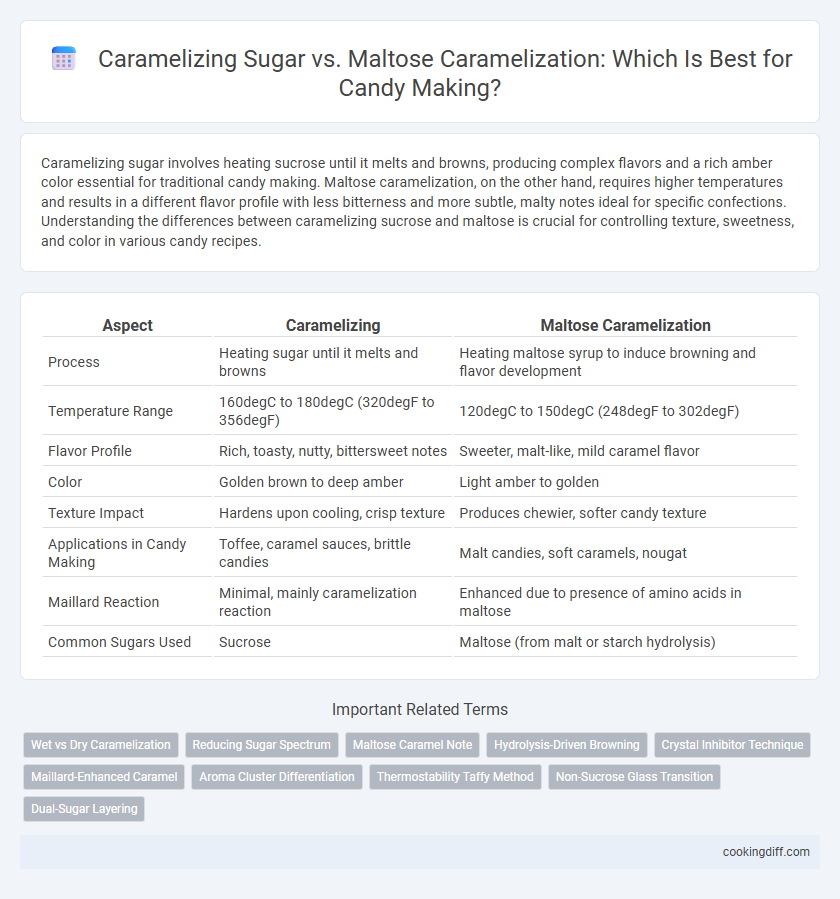

| Aspect | Caramelizing | Maltose Caramelization |

|---|---|---|

| Process | Heating sugar until it melts and browns | Heating maltose syrup to induce browning and flavor development |

| Temperature Range | 160degC to 180degC (320degF to 356degF) | 120degC to 150degC (248degF to 302degF) |

| Flavor Profile | Rich, toasty, nutty, bittersweet notes | Sweeter, malt-like, mild caramel flavor |

| Color | Golden brown to deep amber | Light amber to golden |

| Texture Impact | Hardens upon cooling, crisp texture | Produces chewier, softer candy texture |

| Applications in Candy Making | Toffee, caramel sauces, brittle candies | Malt candies, soft caramels, nougat |

| Maillard Reaction | Minimal, mainly caramelization reaction | Enhanced due to presence of amino acids in maltose |

| Common Sugars Used | Sucrose | Maltose (from malt or starch hydrolysis) |

Introduction to Caramelization in Candy Making

Caramelization is the process of heating sugar to create complex flavors and a golden-brown color essential in candy making. Maltose caramelization involves the specific breakdown of maltose sugars, producing a distinct flavor profile and texture in confections.

- Caramelization - The thermal decomposition of sucrose resulting in rich flavors and color changes critical for candy aesthetics.

- Maltose Caramelization - Involves the caramelization of maltose sugars, yielding unique taste notes and influencing candy texture.

- Flavor Development - Both processes enhance sweetness and add depth, but maltose caramelization offers a milder and more buttery flavor.

What is Maltose Caramelization?

Maltose caramelization is the process of heating maltose sugar until it breaks down into complex flavor compounds, distinct from traditional caramelizing of sucrose. This reaction results in a sweeter, less bitter flavor profile ideal for specific candy applications.

- Maltose Decomposition - Maltose breaks down at a lower temperature than sucrose, leading to unique caramel flavors.

- Flavor Profile - The caramelization of maltose produces a mild, sweet, and buttery taste preferred in confectionery.

- Candy Applications - Maltose caramelization is used to create smooth textures and delicate flavors in candies like maltose taffy and syrups.

Traditional Sugar Caramelization Explained

Traditional sugar caramelization involves heating sucrose until it breaks down and forms complex flavor compounds, resulting in a rich, golden-brown color essential for candy making. This process occurs at approximately 320degF (160degC) and develops deep, nutty, and toasty notes that define classic caramel.

Maltose caramelization differs by caramelizing a disaccharide sugar derived from starch, which typically occurs at a higher temperature and produces a milder, less intense flavor profile. Understanding these distinctions helps candy makers choose the right sugar base to achieve specific textures and taste nuances in their confections.

Key Differences: Maltose vs. Sucrose Caramelization

Caramelizing sucrose involves heating table sugar to high temperatures, resulting in a deep amber color and complex flavor due to sugar decomposition and Maillard reactions. Maltose caramelization occurs at a slightly lower temperature, producing a milder, less bitter flavor profile often preferred in traditional candy making.

- Temperature Thresholds - Sucrose caramelizes around 160degC, whereas maltose caramelizes closer to 150degC, affecting cooking times and methods.

- Flavor Complexity - Sucrose caramelization generates a richer, more robust flavor while maltose offers a subtler sweetness with fewer bitter notes.

- Application in Candy - Maltose caramelization is favored for producing softer, chewier texture in candies, unlike sucrose which is often used for harder, brittle confections.

Understanding the key differences between maltose and sucrose caramelization enables precise control over texture and flavor in candy making.

Temperature Profiles for Caramelizing Sugars

| Caramelizing sugar involves heating sucrose above 320degF (160degC), initiating Maillard reactions and producing complex flavor compounds and a rich brown color essential for traditional candy making. |

| Maltose caramelization occurs at a lower temperature range, approximately 230degF to 270degF (110degC to 130degC), resulting in a milder flavor profile and lighter color, which influences texture and sweetness in confectionery. |

| Precise temperature control between 230degF and 320degF is critical for balancing sugar decomposition rates and achieving desired caramel flavors, with maltose caramelization offering distinct advantages in controlled sweetness and color stability. |

Flavor Profiles: Maltose Caramel vs Standard Caramel

Maltose caramelization produces a milder, less bitter flavor compared to standard caramel, which often delivers a more robust and complex taste with deeper caramel notes. The unique glucose polymers in maltose result in a smoother sweetness and subtle floral undertones, ideal for delicate candy making. Standard caramelization of sucrose tends to create richer, more intense flavor profiles with hints of nuttiness and toffee, favored in traditional caramel confections.

Texture and Appearance in Finished Candies

How do caramelizing and maltose caramelization differ in terms of texture and appearance in finished candies? Caramelizing typically produces a rich amber color and a crisp, brittle texture, ideal for classic caramel candies. Maltose caramelization results in a lighter, glossy appearance with a chewier, more elastic texture, favored for soft candies and glazes.

Practical Applications: When to Choose Maltose

Caramelizing sugar involves heating sucrose to develop complex flavors and a rich amber color, ideal for creating traditional caramel candies and sauces. Maltose caramelization occurs at a higher temperature and produces a milder, less bitter taste, making it suitable for confections requiring subtle sweetness and extended shelf life.

Choose maltose caramelization when making candies that benefit from a glossy finish and chewier texture, such as traditional Chinese maltose taffy or nougat. Maltose also enhances moisture retention in candy, reducing crystallization and improving overall mouthfeel in practical confectionery applications.

Pros and Cons for Candy Makers

Caramelizing sugar involves heating sucrose until it melts and browns, creating a rich flavor and deep amber color ideal for traditional candies. Maltose caramelization occurs at a lower temperature and produces a milder, less bitter taste, which is preferred for softer, chewier sweets.

Caramelizing sugar provides intense flavor and color but requires careful temperature control to avoid burning, which can ruin the batch. Maltose caramelization offers better control and less bitterness, making it suitable for confections like maltose taffy or fudges. Candy makers must choose between the bold taste of caramelized sugar and the gentle profile of maltose caramelization based on the desired texture and flavor intensity.

Related Important Terms

Wet vs Dry Caramelization

Wet caramelization involves dissolving sugar in water before heating, producing a smooth caramel ideal for candies with a consistent texture, while dry caramelization heats sugar directly, creating richer, deeper flavors and a slightly more complex texture. Maltose caramelization, often used in candy making, requires careful temperature control to avoid bitterness and achieve the desired golden color, differing from traditional sucrose caramelization in both process and final flavor profile.

Reducing Sugar Spectrum

Caramelizing involves heating sugars like sucrose to develop complex flavors and a rich brown color, whereas maltose caramelization occurs at higher temperatures and yields a distinct, less sweet profile ideal for specific candy textures. The reducing sugar spectrum in maltose allows for enhanced Maillard reactions, resulting in deeper flavor development compared to traditional caramelization of non-reducing sugars.

Maltose Caramel Note

Maltose caramelization produces a distinctive rich amber color and a milder, less bitter flavor compared to traditional caramelizing of sucrose, making it ideal for candy making that requires a smooth, less burnt taste profile. This process involves heating maltose syrup to specific temperatures where Maillard reactions enhance flavor complexity while maintaining a glossy, stable texture essential for high-quality confectionery.

Hydrolysis-Driven Browning

Caramelizing sugar involves heating sucrose to induce hydrolysis, breaking it down into glucose and fructose, which then undergo browning reactions producing rich flavors and colors essential for candy making. In contrast, maltose caramelization, driven by hydrolysis of maltose into glucose units, results in a different browning profile with distinct taste and texture characteristics favored in specific confectionery applications.

Crystal Inhibitor Technique

Caramelizing sugar involves heating sucrose until it breaks down and forms complex flavor compounds, while maltose caramelization requires higher temperatures and results in a smoother texture due to its unique molecular structure. The Crystal Inhibitor Technique uses additives like glucose or cream of tartar to prevent unwanted crystallization, ensuring a glossy, uniform caramel ideal for candy making.

Maillard-Enhanced Caramel

Maillard-enhanced caramel in candy making involves the interaction between reducing sugars and amino acids, producing deeper flavors and richer colors compared to traditional caramelizing, which primarily relies on sugar melting and browning. Maltose caramelization occurs at higher temperatures and contributes to a distinct sweetness and chewy texture, but integrating Maillard reactions enhances complexity and aroma in confectionery products.

Aroma Cluster Differentiation

Caramelizing sugar involves heating sucrose until it breaks down and forms complex aroma compounds such as furans, aldehydes, and esters, creating a rich, nutty scent profile critical for candy making. Maltose caramelization produces a distinct aroma cluster dominated by maltol and isomaltol, which imparts a sweeter, toasted, and slightly burnt flavor, differentiating the sensory experience from traditional caramelization.

Thermostability Taffy Method

Caramelizing involves heating sugars like sucrose to develop complex flavors and brown color, while maltose caramelization requires higher temperatures due to its greater thermostability, making it ideal for the Taffy Method in candy making. The Taffy Method leverages maltose's resistance to heat breakdown, allowing extended cooking times without burning, resulting in a smooth, pliable candy texture.

Non-Sucrose Glass Transition

Caramelizing involves heating sugars like sucrose to create complex flavors and a characteristic glassy texture, while maltose caramelization occurs at higher temperatures, producing a different flavor profile and glass transition behavior critical for candy stability. The non-sucrose glass transition in maltose caramelization results in distinct thermal and mechanical properties, influencing candy hardness and shelf life compared to traditional sucrose caramelization.

Caramelizing vs Maltose Caramelization for candy making. Infographic

cookingdiff.com

cookingdiff.com