A copper sugar pot offers superior heat conductivity and precise temperature control, making it ideal for evenly caramelizing sugar without burning. In contrast, a saute pan provides a larger surface area for caramelizing ingredients with more volume but may heat less evenly, risking hot spots. Choosing between the two depends on the desired caramel texture and cooking technique, with copper pots excelling in delicate sugar caramelization and saute pans better suited for broader applications.

Table of Comparison

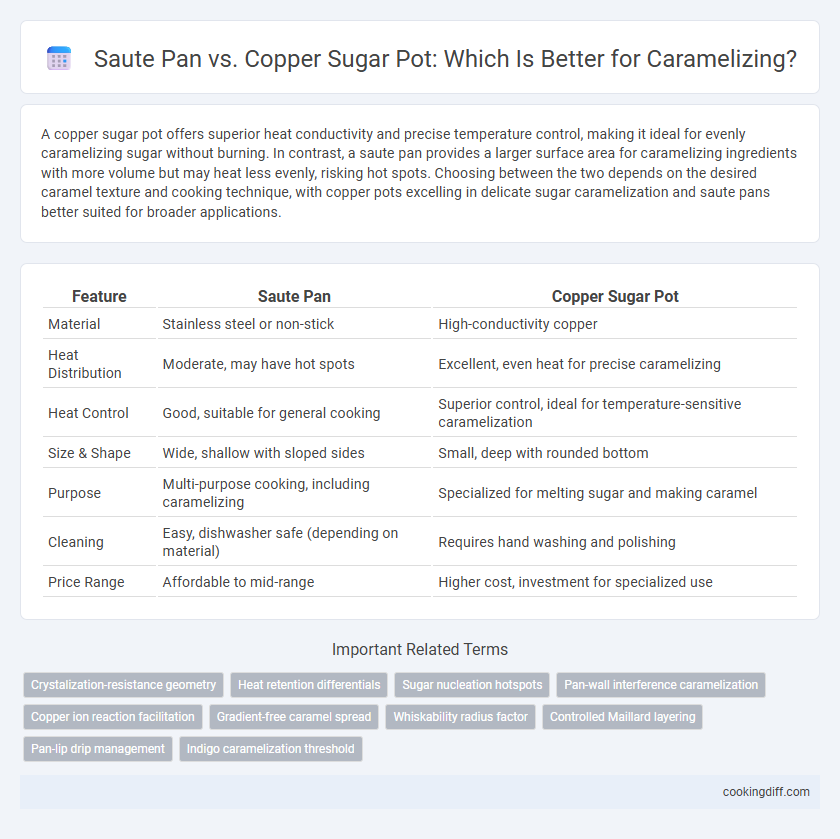

| Feature | Saute Pan | Copper Sugar Pot |

|---|---|---|

| Material | Stainless steel or non-stick | High-conductivity copper |

| Heat Distribution | Moderate, may have hot spots | Excellent, even heat for precise caramelizing |

| Heat Control | Good, suitable for general cooking | Superior control, ideal for temperature-sensitive caramelization |

| Size & Shape | Wide, shallow with sloped sides | Small, deep with rounded bottom |

| Purpose | Multi-purpose cooking, including caramelizing | Specialized for melting sugar and making caramel |

| Cleaning | Easy, dishwasher safe (depending on material) | Requires hand washing and polishing |

| Price Range | Affordable to mid-range | Higher cost, investment for specialized use |

Introduction to Caramelizing: The Right Tools Matter

Choosing the right cookware significantly impacts the caramelizing process, where precise temperature control is essential to achieve perfect browning without burning. A saute pan offers a broad, flat surface ideal for evenly cooking ingredients with less risk of hot spots.

Copper sugar pots provide superior heat conductivity and rapid temperature adjustments, making them a preferred choice for melting sugar and preventing crystallization during caramelizing. Each tool serves a distinct purpose, influencing flavor development and texture in caramelized dishes.

Sauté Pan Overview: Classic Kitchen Workhorse

The saute pan is a classic kitchen workhorse favored for its versatility and even heat distribution, making it ideal for caramelizing due to its wide surface area. Its straight sides and sturdy handle allow for easy stirring and temperature control, essential for preventing sugar from burning during the caramelization process.

Compared to a copper sugar pot, a saute pan offers more capacity and is typically made from stainless steel or aluminum, materials that maintain consistent heat without the high conductivity of copper. While copper pots provide superior temperature responsiveness, the saute pan's durability and everyday usability make it a practical choice for both amateur and professional cooks. Its design facilitates easy deglazing and adds depth of flavor to caramelized dishes, enhancing both complexity and texture in cooking.

Copper Sugar Pot Features: Precision in Sugar Work

Copper sugar pots offer exceptional heat conductivity, allowing precise temperature control essential for caramelizing sugar without burning. Saute pans, while versatile, often lack the fine temperature regulation required for delicate sugar work, leading to uneven caramelization.

- Superior Heat Conductivity - Copper distributes heat evenly, preventing hot spots that can scorch sugar.

- Precise Temperature Control - Allows meticulous adjustments to maintain ideal caramelizing temperatures.

- Specialized Design - The pot's shape facilitates even stirring and uniform caramel formation.

Heat Distribution: Sauté Pan vs Copper Sugar Pot

When caramelizing, the choice between a saute pan and a copper sugar pot significantly impacts heat distribution and control. Copper sugar pots provide superior, even heat conduction essential for preventing hot spots during caramel formation.

- Saute Pan Heat Distribution - Typically made from stainless steel or aluminum, saute pans offer moderate heat distribution but may develop uneven hot spots.

- Copper Sugar Pot Heat Conduction - Copper's excellent thermal conductivity allows for precise temperature control and even heat spread across the pot's surface.

- Caramelizing Efficiency - Even heat in copper sugar pots reduces the risk of burning sugar, ensuring smooth, consistent caramelization compared to saute pans.

Choosing a copper sugar pot over a saute pan enhances caramelization quality by providing more controlled and uniform heat distribution.

Temperature Control and Responsiveness

Saute pans offer moderate temperature control with even heat distribution, suitable for gradual caramelization processes. Copper sugar pots provide superior responsiveness and precise temperature adjustments, essential for preventing sugar from burning.

The high thermal conductivity of copper allows instant heat changes, making it ideal for delicate caramelization where temperature fluctuations must be minimized. Saute pans' thicker base retains heat longer, which can result in less control during rapid temperature shifts.

Ease of Stirring and Access

The saute pan features a wide, flat base with sloped sides, providing ample space and ease of stirring when caramelizing sugar. Copper sugar pots offer superior heat conductivity but typically have higher, straight sides, which can make stirring and accessing the caramel more challenging. For efficient caramelizing, the saute pan allows better maneuverability and constant monitoring of sugar's color and texture.

Cleaning and Maintenance Differences

Which cookware is easier to clean after caramelizing, a saute pan or a copper sugar pot? Copper sugar pots require careful hand washing to maintain their patina and prevent tarnishing, while saute pans, especially those with non-stick surfaces, often allow for simpler cleaning with warm, soapy water. Regular polishing and gentle cleaning are essential for copper pots to preserve their heat conductivity and aesthetic appeal over time.

Suitability for Different Caramel Recipes

The saute pan's wide surface area promotes even caramelization ideal for sauces and savory dishes, while the copper sugar pot's precise heat control suits delicate sugar work and candy making. Each cookware type enhances specific caramel recipes by optimizing heat distribution and control.

- Saute Pan - Offers ample space and even heat, perfect for thick caramel sauces or deglazing meats.

- Copper Sugar Pot - Provides superior temperature control crucial for sugar crystallization and pulling sugar candies.

- Recipe Suitability - Choose the saute pan for robustness and volume, while the copper pot excels in fine, temperature-sensitive sugar caramelizing.

Professional vs Home Kitchen Preferences

Professional kitchens often prefer copper sugar pots for caramelizing due to their superior heat conductivity and precise temperature control, which prevents sugar from burning and ensures a smooth caramel. Home kitchens typically use saute pans because they are more versatile and easier to handle for multiple cooking tasks beyond caramelizing. Copper pots require more maintenance and skill, making saute pans a practical choice for everyday home cooks seeking convenience and durability.

Related Important Terms

Crystalization-resistance geometry

A copper sugar pot's rounded geometry minimizes surface area where sugar crystals can form, enhancing crystallization resistance during caramelizing. In contrast, a saute pan's flat, angular design increases edges prone to crystal formation, making copper sugar pots more effective for smooth caramel production.

Heat retention differentials

Copper sugar pots excel in heat retention and even heat distribution, allowing for precise temperature control essential in caramelizing sugar without burning. Saute pans, often made from stainless steel or aluminum, heat up quickly but lose heat more rapidly, which can result in uneven caramelization and temperature fluctuations.

Sugar nucleation hotspots

Saute pans often create uneven heat distribution leading to sugar nucleation hotspots that cause crystallization during caramelizing, while copper sugar pots provide superior thermal conductivity for consistent, controlled heat that minimizes nucleation and ensures smooth caramel formation. The precise temperature control of copper pots prevents localized overheating, which is critical for avoiding sugar graininess and achieving a uniform caramel texture.

Pan-wall interference caramelization

Copper sugar pots provide superior heat conductivity and precise temperature control, minimizing pan-wall interference during caramelization, which reduces uneven burning and crystallization. In contrast, saute pans with thicker walls often create inconsistent heat distribution, leading to localized hot spots that interfere with smooth caramel formation.

Copper ion reaction facilitation

Copper sugar pots enhance the caramelizing process by facilitating ionic reactions between copper ions and sugar molecules, resulting in more even heat distribution and controlled caramelization. In contrast, saute pans made of stainless steel or aluminum lack this ionic interaction, often leading to uneven browning and increased risk of burning.

Gradient-free caramel spread

Copper sugar pots provide superior heat conductivity and even temperature control, ensuring a gradient-free caramel spread essential for flawless caramelizing, unlike saute pans which often create uneven hot spots. The uniform heat distribution in copper sugar pots prevents burning and promotes a smooth, consistent caramel texture.

Whiskability radius factor

A copper sugar pot offers superior heat conductivity and a rounded whiskability radius that ensures even caramelization without scorching, ideal for precise temperature control. In contrast, a saute pan's wider, flatter base reduces the whiskability radius, increasing the risk of uneven caramel formation and hotspots during cooking.

Controlled Maillard layering

Saute pans provide broad, even heat distribution essential for controlled Maillard layering during caramelizing, allowing sugars to develop complex flavors without burning. Copper sugar pots offer superior heat conductivity and precise temperature control, enabling delicate caramelization with minimal temperature fluctuations for consistent color and flavor profiles.

Pan-lip drip management

Saute pans with a flared lip provide superior drip management during caramelizing by allowing controlled pouring and reducing sugar spills, while copper sugar pots often lack this design feature, leading to increased risk of sticky drips. The thick copper base in sugar pots offers even heat distribution crucial for caramelization, but their straight-sided lips do not facilitate efficient drip control compared to saute pans.

Sauté pan vs Copper sugar pot for Caramelizing. Infographic

cookingdiff.com

cookingdiff.com