Caramelizing involves heating sugar until it melts and turns a deep amber color, developing a rich, complex flavor ideal for sauces. Ambering refers to the stage where sugar reaches a lighter, golden hue, offering a milder taste and more delicate aroma. Choosing between caramelizing and ambering depends on the desired intensity and depth of flavor in the sauce.

Table of Comparison

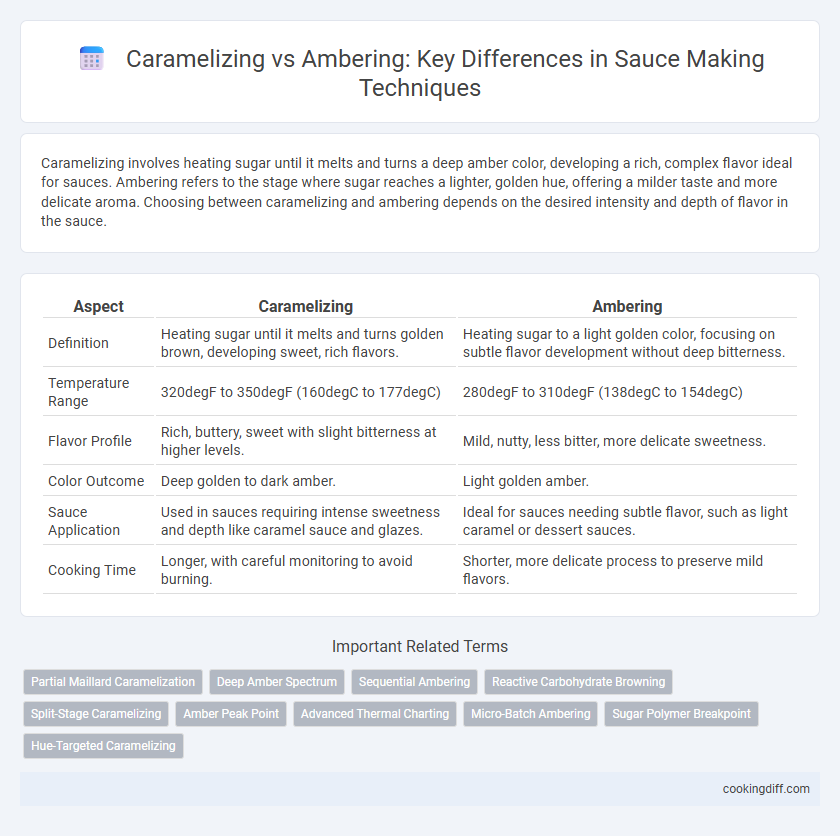

| Aspect | Caramelizing | Ambering |

|---|---|---|

| Definition | Heating sugar until it melts and turns golden brown, developing sweet, rich flavors. | Heating sugar to a light golden color, focusing on subtle flavor development without deep bitterness. |

| Temperature Range | 320degF to 350degF (160degC to 177degC) | 280degF to 310degF (138degC to 154degC) |

| Flavor Profile | Rich, buttery, sweet with slight bitterness at higher levels. | Mild, nutty, less bitter, more delicate sweetness. |

| Color Outcome | Deep golden to dark amber. | Light golden amber. |

| Sauce Application | Used in sauces requiring intense sweetness and depth like caramel sauce and glazes. | Ideal for sauces needing subtle flavor, such as light caramel or dessert sauces. |

| Cooking Time | Longer, with careful monitoring to avoid burning. | Shorter, more delicate process to preserve mild flavors. |

Understanding Caramelizing and Ambering: Key Differences

Caramelizing involves heating sugar until it melts and develops a rich, complex flavor with a deep brown color, typically ranging from 320degF to 350degF (160degC to 175degC). Ambering refers to the stage just before full caramelization, where sugar reaches a golden amber hue, offering a milder sweetness and less bitterness ideal for balanced sauces.

Understanding the key differences in temperature and flavor profile between caramelizing and ambering is essential for sauce making, as caramelizing produces intense, robust notes while ambering provides subtle, nuanced sweetness. Chefs use ambering to enhance sauces without overpowering other ingredients, whereas caramelizing is suited for recipes demanding deeper, more pronounced caramel flavors.

The Science Behind Caramelizing and Ambering

What distinguishes caramelizing from ambering in sauce making? Caramelizing involves heating sugar until it reaches a deep brown color around 340degF, developing complex flavors through Maillard reactions and sugar decomposition. Ambering occurs at a lower temperature range, producing a lighter color and more subtle, sweet notes ideal for delicate sauces.

Flavor Profiles: Caramelization vs. Ambering

| Technique | Flavor Profile |

|---|---|

| Caramelizing | Develops a rich, deep sweetness with complex notes of toffee and butterscotch, enhancing sauces with a robust, layered flavor. |

| Ambering | Produces a milder, nutty sweetness that balances subtle bitterness, ideal for delicate sauces requiring a nuanced finish without overpowering base ingredients. |

When to Use Caramelizing for Sauce Making

Caramelizing is ideal for sauce making when a rich, deep flavor and a dark, robust color are desired, such as in brown sauces or gravies. It involves slowly cooking sugar or onions until they develop a sweet, complex taste, enhancing the sauce's umami profile. Use caramelizing when you want to add sweetness and depth without bitterness, unlike ambering which is lighter and less intense.

The Role of Ambering in Sauce Recipes

Ambering plays a crucial role in sauce recipes by developing rich, complex flavors through controlled caramelization of sugars. This process enhances depth without the bitterness often associated with over-caramelizing, making sauces more balanced and appealing.

- Flavor Development - Ambering creates a nuanced sweetness that enriches the overall taste profile of sauces.

- Color Enhancement - It imparts a warm golden hue, adding visual appeal to sauce presentations.

- Bitterness Control - The precise ambering stage prevents the bitter notes that can result from over-caramelization.

Step-by-Step Guide to Caramelizing Sugar

Caramelizing sugar involves slowly heating sugar until it melts and turns golden brown, creating a rich, complex flavor ideal for sauces. Ambering refers to cooking sugar to a slightly lighter stage, offering a milder taste and lighter color than full caramelization.

- Start with even sugar distribution - Pour an even layer of sugar into a dry pan to ensure uniform melting.

- Heat over medium heat without stirring - Allow the sugar to melt gradually, occasionally swirling the pan to prevent burning.

- Observe color change carefully - Remove from heat once the sugar reaches the desired amber or deep caramel hue to avoid bitterness.

Achieving the Perfect Amber: Techniques and Tips

Achieving the perfect amber color in sauce making requires precise temperature control, typically between 320degF to 350degF, to develop rich, deep flavors without burning the sugar. Unlike caramelizing, which focuses on melting sugar into a golden brown, ambering involves a lower heat and longer cooking time to enhance the sauce's complexity and balance. Using a heavy-bottomed pan and constant stirring prevents uneven cooking and ensures a smooth, flavorful sauce with the ideal amber hue.

Common Mistakes in Caramelizing and Ambering

Common mistakes in caramelizing include overheating the sugar, which causes burning and results in a bitter taste, as well as stirring too aggressively, leading to crystallization. Ambering, on the other hand, often suffers from insufficient browning time, producing a pale, underdeveloped flavor not suitable for rich sauces.

Failing to monitor the temperature closely during caramelizing and ambering processes can cause inconsistent color and flavor profiles, risking the sauce's overall quality. Using low-quality sugar or improper pan materials also contributes to uneven caramel or amber development, compromising texture and taste.

Sauce Recipes Highlighting Caramelization and Ambering

Caramelizing intensifies natural sugars in ingredients, creating rich, deep flavors essential for sauces like caramel sauce or balsamic glaze. Ambering, a stage in caramelization where sugar turns golden brown, adds a subtle nutty taste ideal for delicate sauces such as beurre noisette or light caramel sauces.

Sauce recipes leveraging caramelization often rely on slow cooking to develop complex flavors, like in caramelized onion sauce or apple caramel sauce. Ambering is precise, requiring careful temperature control around 320degF to prevent burning while enhancing aroma and color. Both techniques elevate sauces by balancing sweetness with depth, making them indispensable in culinary applications.

Related Important Terms

Partial Maillard Caramelization

Caramelizing involves heating sugars until they break down and develop rich, sweet flavors, while ambering refers to achieving a deep golden-brown color through controlled browning. Partial Maillard caramelization in sauce making enhances complexity by combining caramelized sugars with amino acids, producing nuanced savory-sweet notes unattainable by caramelizing or ambering alone.

Deep Amber Spectrum

Caramelizing involves heating sugar until it melts and turns into a deep amber spectrum, producing rich, complex flavors essential for sauce making, whereas ambering refers to a lighter caramel stage with a milder taste. The deep amber spectrum enhances sauces with robust, bittersweet notes and a darker color, improving depth and richness in culinary applications.

Sequential Ambering

Sequential ambering in sauce making builds layers of flavor by gradually developing deeper, nuttier notes compared to the straightforward caramelizing process that primarily enhances sweetness. This technique involves carefully timing the oxidation and Maillard reaction stages to achieve a complex balance of color and taste essential for rich, well-rounded sauces.

Reactive Carbohydrate Browning

Caramelizing involves heating sugars to develop complex flavors and a rich amber color through Maillard reactions and reactive carbohydrate browning, essential for deepening sauce profiles. Ambering, a lighter stage of browning, emphasizes mild sweetness and color without the intense flavor complexity achieved by full caramelization, influencing the sauce's taste and texture subtly.

Split-Stage Caramelizing

Split-stage caramelizing enhances sauce depth by initially melting sugar to a clear syrup before progressing to an amber color, allowing precise control over flavor development and bitterness. This method contrasts with traditional caramelizing, which often risks burning, as the intermediate stage ensures a balanced, rich complexity ideal for sophisticated sauces.

Amber Peak Point

Caramelizing involves heating sugar until it melts and turns golden brown, enhancing flavor complexity, while ambering reaches the Amber Peak Point, where sugar attains a deep amber color and richer, slightly bitter notes essential for refined sauce depth. Controlling the Amber Peak Point precisely is crucial to avoid burning and achieve optimal balance in sauce texture and taste.

Advanced Thermal Charting

Caramelizing involves heating sugar to around 170degC (338degF) to develop complex flavors and deep browning, whereas ambering occurs at a lower temperature of approximately 140degC (284degF), producing a milder sweetness and lighter color. Advanced thermal charting reveals these temperature-dependent stages optimize sauce texture and flavor profiles by controlling Maillard reactions and sugar polymerization rates.

Micro-Batch Ambering

Micro-batch ambering offers precise control over sugar caramelization, resulting in a deeper, more complex flavor profile ideal for sauce making compared to traditional caramelizing methods. This technique involves slowly heating sugars to the amber stage (around 340degF or 170degC) to develop rich color and nuanced taste without burning, enhancing sauces with balanced sweetness and bitterness.

Sugar Polymer Breakpoint

Caramelizing involves heating sugar to reach its polymer breakpoint around 320degF (160degC), resulting in a rich, complex flavor and deep amber color ideal for sauces. Ambering, conducted at lower temperatures near 280degF (140degC), enhances sweetness and color without extensive polymer breakdown, producing a milder caramel flavor profile.

Caramelizing vs Ambering for sauce making Infographic

cookingdiff.com

cookingdiff.com