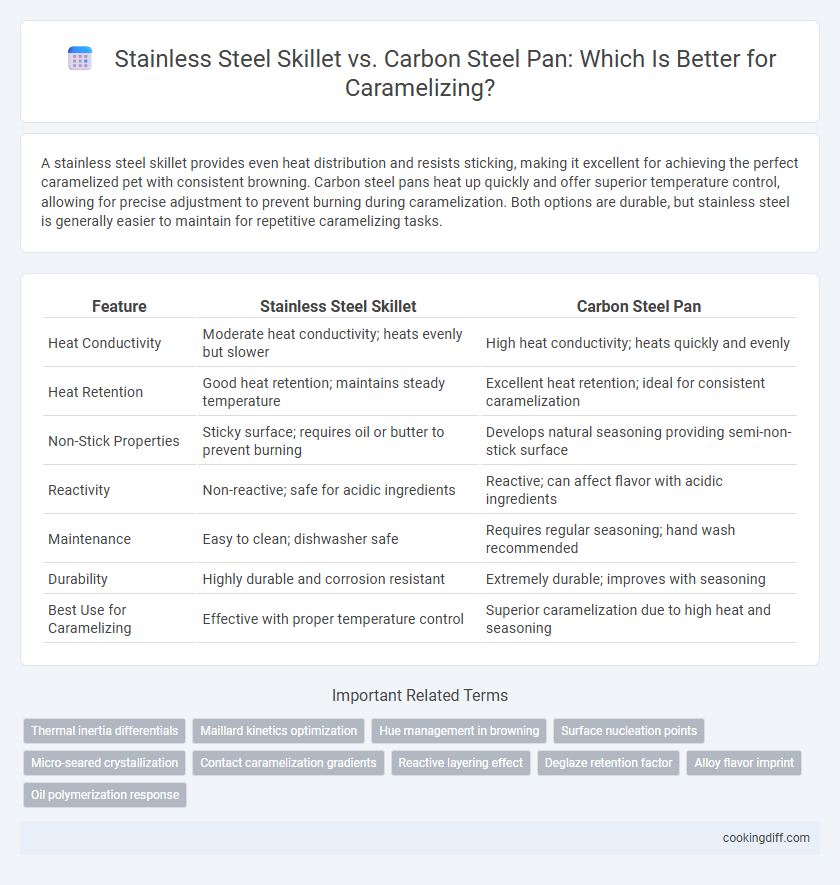

A stainless steel skillet provides even heat distribution and resists sticking, making it excellent for achieving the perfect caramelized pet with consistent browning. Carbon steel pans heat up quickly and offer superior temperature control, allowing for precise adjustment to prevent burning during caramelization. Both options are durable, but stainless steel is generally easier to maintain for repetitive caramelizing tasks.

Table of Comparison

| Feature | Stainless Steel Skillet | Carbon Steel Pan |

|---|---|---|

| Heat Conductivity | Moderate heat conductivity; heats evenly but slower | High heat conductivity; heats quickly and evenly |

| Heat Retention | Good heat retention; maintains steady temperature | Excellent heat retention; ideal for consistent caramelization |

| Non-Stick Properties | Sticky surface; requires oil or butter to prevent burning | Develops natural seasoning providing semi-non-stick surface |

| Reactivity | Non-reactive; safe for acidic ingredients | Reactive; can affect flavor with acidic ingredients |

| Maintenance | Easy to clean; dishwasher safe | Requires regular seasoning; hand wash recommended |

| Durability | Highly durable and corrosion resistant | Extremely durable; improves with seasoning |

| Best Use for Caramelizing | Effective with proper temperature control | Superior caramelization due to high heat and seasoning |

Introduction to Caramelizing: Why Pan Selection Matters

Stainless steel skillets offer excellent heat retention and even cooking, making them ideal for precise caramelization without hot spots. Their non-reactive surface prevents acidic ingredients from altering the flavor during the caramelizing process.

Carbon steel pans heat up quickly and provide superior responsiveness to temperature changes, crucial for controlling caramel color and depth. The natural seasoning on carbon steel enhances release of sugars, aiding in the development of complex caramel flavors.

Stainless Steel Skillet Overview: Key Features

Stainless steel skillets offer excellent heat retention and even cooking temperature, crucial for achieving perfect caramelization without burning. Their non-reactive surface ensures that the caramel's flavor remains pure and uncontaminated by metallic tastes.

Stainless steel skillets are highly durable, resistant to rust and corrosion, and easy to clean after caramelizing sticky sugars. The surface allows for precise temperature control, preventing hot spots that can cause uneven caramelization. These features make stainless steel a reliable choice for both professional chefs and home cooks aiming for consistent caramelized dishes.

Carbon Steel Pan Overview: Key Features

Carbon steel pans are highly favored for caramelizing due to their excellent heat conductivity and quick response to temperature changes. Their naturally non-stick surface improves with seasoning, allowing precise control over caramelization without burning.

The lightweight design and durability of carbon steel pans make them easy to handle and long-lasting in professional kitchens. They develop a rich patina that enhances flavor, making them ideal for achieving consistent, deep caramelization results.

Heat Conductivity: Stainless Steel vs Carbon Steel

Carbon steel pans offer superior heat conductivity compared to stainless steel skillets, allowing for more even and consistent caramelization. Stainless steel tends to heat unevenly but retains heat longer, which can impact the caramelizing process.

- Carbon Steel Superior Conductivity - Carbon steel quickly absorbs and distributes heat, reducing hot spots during caramelization.

- Stainless Steel Heat Retention - Stainless steel heats slower but holds temperature, useful for prolonged caramelizing sessions.

- Thermal Responsiveness - Carbon steel responds faster to temperature changes, giving precise control over caramelization stages.

Choosing between these pans depends on the desired caramelizing control and heat management.

Browning and Maillard Reaction Performance

Carbon steel pans excel in caramelizing due to their superior heat conductivity and retention, promoting even browning and enhanced Maillard reactions. Stainless steel skillets offer durability and resistance to corrosion but often require higher heat and longer cooking times for similar caramelization results. The pronounced heat responsiveness of carbon steel creates a more consistent and efficient surface for developing rich flavors during the caramelization process.

Stickiness and Release: Which Pan Is Better?

| Stainless Steel Skillet | Stainless steel offers excellent heat retention and even cooking, but can cause caramelized sugar to stick more due to its less porous surface. Thorough preheating and oiling are required to minimize sticking when caramelizing. Its non-reactive nature prevents flavor alterations during the caramelization process. |

| Carbon Steel Pan | Carbon steel pans develop a natural seasoning layer that improves release over time, reducing stickiness during caramelization. Their superior heat conductivity ensures quick temperature adjustments, critical for preventing burning. Properly seasoned carbon steel pans provide easier sugar release and better caramelization control compared to stainless steel. |

Durability and Maintenance Comparison

Carbon steel pans offer excellent durability with their ability to withstand high heat and develop a natural non-stick patina over time, making them ideal for caramelizing. Stainless steel skillets are highly resistant to rust and corrosion, requiring less frequent seasoning but demanding more careful cleaning to prevent discoloration. Both materials require proper maintenance: carbon steel needs regular seasoning to maintain its surface, while stainless steel benefits from thorough drying and occasional polishing to preserve its finish.

Ease of Cleaning: Stainless Steel vs Carbon Steel

Stainless steel skillets are generally easier to clean after caramelizing due to their non-reactive surface and resistance to sticking. Carbon steel pans require more attentive cleaning and seasoning to maintain their non-stick properties and prevent rust.

- Stainless steel is dishwasher safe - It can be cleaned with detergents without damaging the surface.

- Carbon steel needs hand washing - Avoid soap to protect the seasoning layer that aids in non-stick performance.

- Carbon steel requires regular seasoning - This process prevents rust and enhances ease of cleaning over time.

Best Uses for Each Pan in Caramelizing

Stainless steel skillets offer even heat distribution making them ideal for slow, precise caramelizing of sugars and vegetables without hot spots. Carbon steel pans heat up quickly and retain high temperatures, perfect for rapid caramelization and achieving a deep, rich color on meats and sugars.

- Stainless steel skillet for controlled caramelizing - Provides consistent, moderate heat suited for delicate caramelization tasks like onions and fruits.

- Carbon steel pan for high-heat caramelizing - Excels at quick searing and caramelizing sugars or proteins at high temperatures.

- Maintenance differences - Stainless steel resists sticking with proper technique, while carbon steel requires seasoning to develop a natural non-stick surface enhancing caramelization.

Related Important Terms

Thermal inertia differentials

Stainless steel skillets exhibit higher thermal inertia, maintaining consistent heat during caramelization but requiring longer preheating times, while carbon steel pans heat up quickly and respond rapidly to temperature changes, enabling precise control over browning. The lower thermal mass of carbon steel facilitates faster caramelization adjustments, reducing the risk of burning compared to stainless steel's more stable but slower heat response.

Maillard kinetics optimization

A carbon steel pan heats more evenly and retains higher temperatures compared to a stainless steel skillet, enhancing Maillard kinetics for optimal caramelization by promoting faster and more uniform browning reactions. This efficient heat conduction accelerates the chemical processes responsible for flavor and color development, yielding superior caramelized results.

Hue management in browning

Carbon steel pans excel in hue management during caramelizing due to their rapid, even heat distribution and natural non-stick patina that enhances precise browning control. Stainless steel skillets, while durable and resistant to corrosion, often require higher heat and careful temperature regulation to avoid uneven browning and maintain optimal caramelization hues.

Surface nucleation points

Stainless steel skillets offer numerous surface nucleation points due to their textured finish, promoting even caramelization and browning of sugars. Carbon steel pans, with their smoother surface, provide fewer nucleation sites but heat up quickly, requiring careful temperature control to achieve consistent caramelization.

Micro-seared crystallization

Stainless steel skillets excel in maintaining even heat distribution for consistent micro-seared crystallization during caramelizing, creating a uniform golden crust without sticking. Carbon steel pans develop a natural nonstick patina over time, allowing precise temperature control and enhanced caramel flavor through optimal micro-searing and browning reactions.

Contact caramelization gradients

Stainless steel skillets offer more consistent heat distribution, producing uniform caramelization with minimal hot spots, while carbon steel pans excel at developing intense contact caramelization gradients due to their superior heat retention and quick responsiveness. The carbon steel's ability to rapidly fluctuate temperature at the surface creates richer browning contrasts, enhancing flavor complexity during caramelization compared to the steadier, more even gradients of stainless steel.

Reactive layering effect

A carbon steel pan develops a reactive layering effect through seasoning, enhancing its ability to achieve even caramelization by promoting optimal browning and depth of flavor. In contrast, a stainless steel skillet lacks this reactive layer, often resulting in less controlled caramelization and a higher likelihood of food sticking during the cooking process.

Deglaze retention factor

A carbon steel pan offers superior heat retention and even heating compared to a stainless steel skillet, enhancing the deglaze retention factor crucial for rich, deep caramelized flavors. The reactive surface of carbon steel also promotes better fond development, allowing more flavorful fond bits to deglaze and integrate into sauces.

Alloy flavor imprint

Stainless steel skillets offer a neutral alloy composition that minimizes flavor imprint, preserving the pure, sweet profile of caramelized sugars, while carbon steel pans may impart a subtle metallic taste due to their higher carbon content reacting during high-heat cooking. Choosing stainless steel for caramelizing ensures the clean, natural flavor of caramel is highlighted without interference from the pan's material.

Stainless steel skillet vs carbon steel pan for caramelizing. Infographic

cookingdiff.com

cookingdiff.com