Using a sugar thermometer provides precise temperature control essential for successful caramelizing, measuring the heat directly in the sugar mixture, which ensures accurate melting and browning. An instant-read infrared thermometer offers quick, non-contact readings but may be less reliable because it only measures the surface temperature and can be affected by steam or reflective surfaces. For consistent caramelizing results, a sugar thermometer is generally preferred due to its accuracy in monitoring the critical stages of sugar cooking.

Table of Comparison

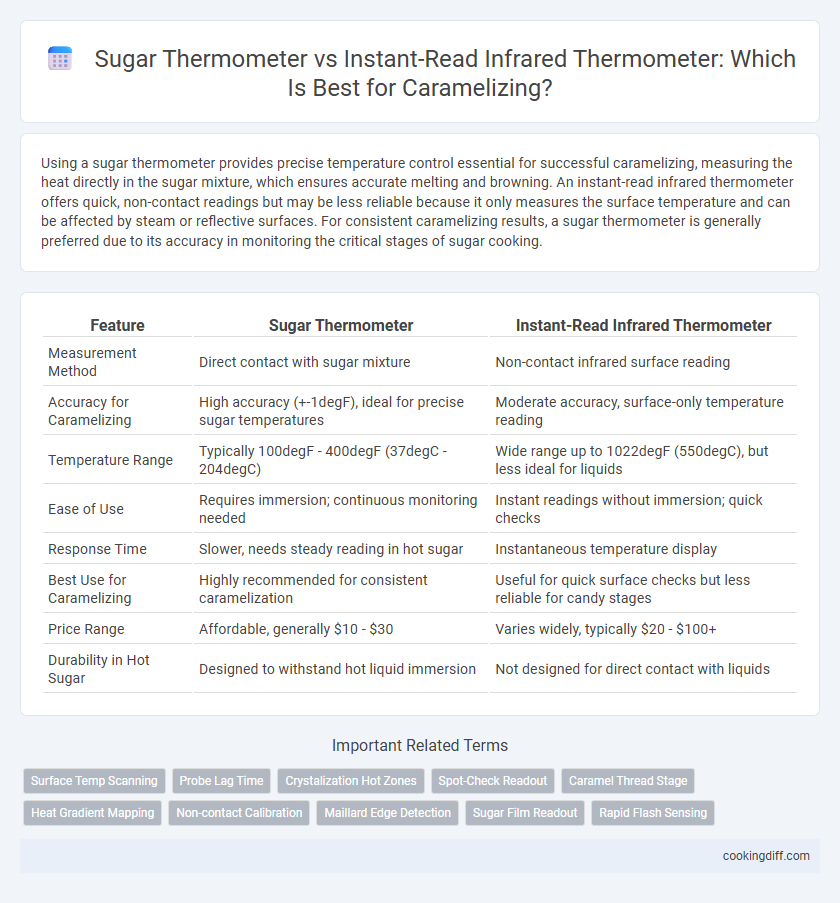

| Feature | Sugar Thermometer | Instant-Read Infrared Thermometer |

|---|---|---|

| Measurement Method | Direct contact with sugar mixture | Non-contact infrared surface reading |

| Accuracy for Caramelizing | High accuracy (+-1degF), ideal for precise sugar temperatures | Moderate accuracy, surface-only temperature reading |

| Temperature Range | Typically 100degF - 400degF (37degC - 204degC) | Wide range up to 1022degF (550degC), but less ideal for liquids |

| Ease of Use | Requires immersion; continuous monitoring needed | Instant readings without immersion; quick checks |

| Response Time | Slower, needs steady reading in hot sugar | Instantaneous temperature display |

| Best Use for Caramelizing | Highly recommended for consistent caramelization | Useful for quick surface checks but less reliable for candy stages |

| Price Range | Affordable, generally $10 - $30 | Varies widely, typically $20 - $100+ |

| Durability in Hot Sugar | Designed to withstand hot liquid immersion | Not designed for direct contact with liquids |

Understanding Caramelizing: Why Temperature Matters

Which thermometer is more accurate for caramelizing sugar? A sugar thermometer provides precise temperature readings critical for achieving the perfect caramel stage, typically between 320degF and 350degF. Instant-read infrared thermometers measure surface temperature quickly but may not accurately reflect the sugar's internal temperature, impacting caramel consistency.

Introduction to Sugar Thermometers

Sugar thermometers are essential for precise temperature control when caramelizing sugar, ensuring optimal texture and flavor. They measure the temperature of the sugar syrup accurately, typically ranging from 100degF to 400degF, crucial for achieving the correct caramel stage.

Instant-read infrared thermometers provide quick, non-contact temperature readings but may be less accurate for thick, bubbling sugar mixtures. Sugar thermometers, often with a clip for pot attachment, offer consistent monitoring during the caramelizing process, preventing burning or undercooking.

Instant-Read Infrared Thermometers: How They Work

Instant-read infrared thermometers measure surface temperature by detecting the infrared radiation emitted by caramelizing sugar. These devices provide quick, contactless temperature readings, making them ideal for monitoring delicate sugar caramelization without disturbing the process. Unlike traditional sugar thermometers, infrared thermometers offer precise control by instantly displaying temperature variations, ensuring perfectly caramelized results every time.

Accuracy in Caramelizing: Comparing Both Thermometers

Accuracy is crucial when caramelizing sugar to achieve the perfect color and flavor without burning. Sugar thermometers provide precise internal temperature readings, while instant-read infrared thermometers measure surface temperatures, affecting their reliability in caramelization.

- Sugar thermometer accuracy - Measures the internal temperature of the sugar solution for precise control.

- Instant-read infrared thermometer precision - Measures surface temperature only, which can be less accurate for thick sugar mixtures.

- Temperature range suitability - Sugar thermometers typically cover higher ranges needed for caramelization up to 400degF (204degC).

Using a sugar thermometer ensures more consistent caramelization results than relying on infrared readings alone.

Speed and Convenience: Which Tool Wins?

Sugar thermometers provide precise temperature readings crucial for perfect caramelization but require immersion and take longer to stabilize. Instant-read infrared thermometers offer rapid surface temperature measurements without contact, enabling faster checks and greater convenience. For speed and ease during caramelizing, infrared thermometers often outperform traditional sugar thermometers despite slightly less accuracy on internal temperatures.

Versatility in the Kitchen: Beyond Caramelizing

| Sugar Thermometer | Specifically designed to measure the high temperatures required for candy-making and caramelizing, with precise accuracy in the 200degF to 400degF range. |

| Instant-Read Infrared Thermometer | Offers versatile temperature readings across various cooking processes, suitable for grilling, searing, and checking surface temperatures without contact, beyond just caramelizing. |

Safety Considerations During Caramelization

Using a sugar thermometer during caramelization ensures precise temperature control, reducing the risk of overheating and burning sugar, which can release harmful fumes. It provides a direct and safe way to monitor temperatures up to 400degF, essential for achieving the perfect caramel consistency without accidents.

Instant-read infrared thermometers offer a contactless method, helping avoid burns from hot sugar, but may give less accurate surface temperature readings. Proper calibration and aiming techniques are crucial to prevent undercooking or overheating caramel. Both tools require careful handling to maintain kitchen safety and prevent burns, with the sugar thermometer preferred for its accuracy in the high-temperature caramelizing process.

Cost Comparison: Sugar vs. Infrared Thermometers

Sugar thermometers are generally more affordable than instant-read infrared thermometers, making them a popular choice for home caramelizing. Infrared thermometers tend to be pricier but offer non-contact temperature readings which can enhance precision in candy-making.

- Initial Cost - Sugar thermometers typically cost between $10 and $20, while infrared thermometers range from $30 to $100.

- Durability and Use - Sugar thermometers are durable and designed for immersion in hot sugar mixtures, unlike some infrared models which may be less suited for direct contact.

- Value Over Time - Although more expensive upfront, infrared thermometers provide faster readings and reduce the risk of contamination, potentially saving time and improving quality.

Experts’ Recommendations for Caramelizing Success

Experts emphasize the importance of precise temperature control when caramelizing sugar to achieve the perfect amber color and flavor. While sugar thermometers provide direct contact measurement for accurate readings, instant-read infrared thermometers offer quick surface temperature checks without disturbing the caramel.

- Sugar Thermometer Accuracy - Provides consistent and reliable contact temperature readings essential for monitoring sugar's critical stages.

- Instant-Read Infrared Speed - Allows rapid, non-contact surface temperature measurement but may miss internal temperature variations.

- Expert Preference - Professionals often recommend sugar thermometers for caramelizing due to their precision in detecting caramelization thresholds.

Related Important Terms

Surface Temp Scanning

A sugar thermometer provides precise internal temperature readings essential for achieving the exact caramelization stage, while an instant-read infrared thermometer excels at surface temperature scanning to monitor the caramel's exterior without contact. For optimal caramelizing results, combining both tools allows accurate control of sugar's internal heat and surface color development.

Probe Lag Time

Sugar thermometers feature a probe that directly contacts the sugar mixture, providing accurate temperature readings with minimal lag time essential for precise caramelization stages. In contrast, instant-read infrared thermometers measure surface temperature without contact but often suffer from probe lag time due to external factors like steam or reflections, potentially leading to less reliable results in caramelizing processes.

Crystalization Hot Zones

Sugar thermometers provide precise temperature readings essential for identifying critical caramelization stages and avoiding crystallization hot zones during the cooking process. Instant-read infrared thermometers, although quick and convenient, may struggle to accurately detect localized temperature variations on sugary surfaces, increasing the risk of uneven caramelization and unwanted crystal formation.

Spot-Check Readout

Sugar thermometers provide a continuous, precise temperature readout essential for monitoring caramelization stages in real time, while instant-read infrared thermometers offer rapid spot-check readings ideal for verifying surface temperatures without contact. For accurate caramelizing, sugar thermometers ensure consistent heat control, whereas infrared thermometers deliver quick, non-invasive temperature checks but may miss internal sugar temperature variations.

Caramel Thread Stage

Sugar thermometers provide precise temperature readings essential for reaching the caramel thread stage, typically around 230degF to 235degF, ensuring consistent caramelization. Instant-read infrared thermometers measure surface temperature quickly but may not accurately reflect the internal temperature of the syrup, risking under- or over-caramelization.

Heat Gradient Mapping

A sugar thermometer provides precise, direct contact temperature readings essential for monitoring sugar's exact boiling point during caramelizing, ensuring accurate heat gradient mapping within the cooking medium. Instant-read infrared thermometers offer rapid surface temperature measurements but lack the ability to capture internal heat gradients, making them less reliable for the nuanced temperature control required in caramelization processes.

Non-contact Calibration

Using an instant-read infrared thermometer for caramelizing offers precise, non-contact temperature measurement, reducing contamination risk and enabling quick calibration without touching the hot sugar surface. Sugar thermometers require direct contact, which can introduce inconsistencies and slow the cooking process compared to the rapid, accurate readings provided by infrared devices.

Maillard Edge Detection

Sugar thermometers provide precise temperature measurements essential for achieving the Maillard edge during caramelizing, ensuring accurate caramelization stages. Instant-read infrared thermometers offer rapid surface temperature readings but may lack the depth needed for consistent Maillard reaction control.

Sugar Film Readout

A sugar thermometer provides precise temperature readings crucial for caramelizing sugar efficiently, allowing cooks to monitor the exact stage of sugar caramelization through sugar film readout. In contrast, an instant-read infrared thermometer offers surface temperature measurement but lacks the accuracy needed to assess the sugar film's consistency and proper caramelization point.

Sugar thermometer vs Instant-read infrared thermometer for caramelizing. Infographic

cookingdiff.com

cookingdiff.com