An induction-ready saucepan offers precise and even heat distribution essential for perfect caramelizing, preventing hot spots that can burn sugar. Regular saucepans may not provide consistent heat, resulting in uneven caramelization and increased risk of crystallization. Investing in an induction-compatible pan enhances control and efficiency during the caramelizing process.

Table of Comparison

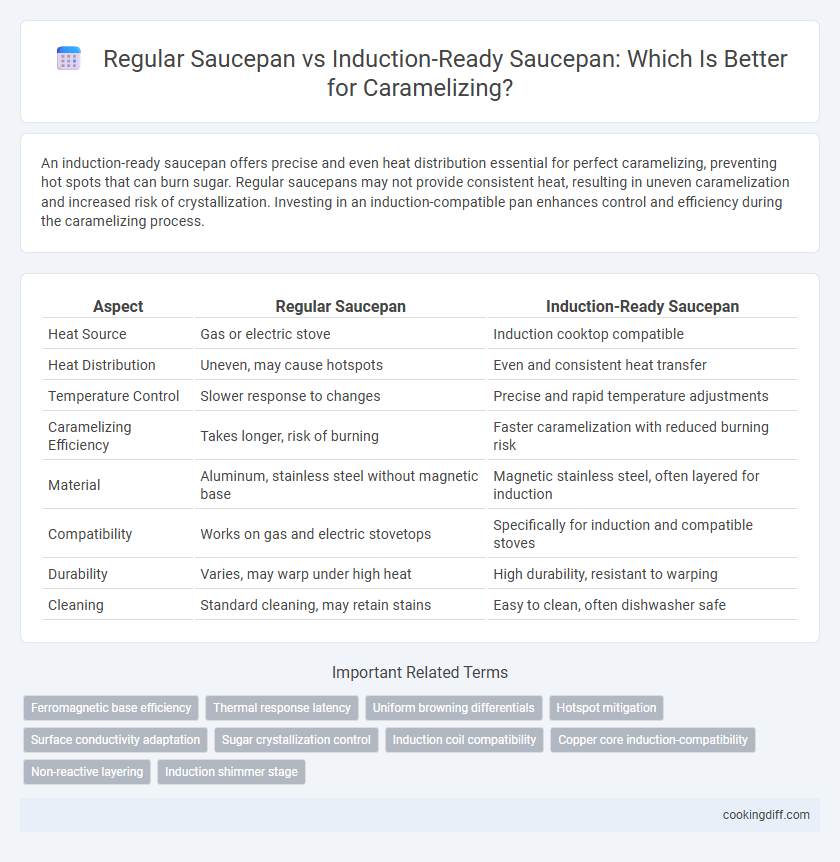

| Aspect | Regular Saucepan | Induction-Ready Saucepan |

|---|---|---|

| Heat Source | Gas or electric stove | Induction cooktop compatible |

| Heat Distribution | Uneven, may cause hotspots | Even and consistent heat transfer |

| Temperature Control | Slower response to changes | Precise and rapid temperature adjustments |

| Caramelizing Efficiency | Takes longer, risk of burning | Faster caramelization with reduced burning risk |

| Material | Aluminum, stainless steel without magnetic base | Magnetic stainless steel, often layered for induction |

| Compatibility | Works on gas and electric stovetops | Specifically for induction and compatible stoves |

| Durability | Varies, may warp under high heat | High durability, resistant to warping |

| Cleaning | Standard cleaning, may retain stains | Easy to clean, often dishwasher safe |

Introduction to Caramelizing: Why Pan Choice Matters

Caramelizing requires precise temperature control and even heat distribution, making pan choice crucial for successful results. Regular saucepans often have uneven heating, leading to inconsistent caramelization and potential burning. Induction-ready saucepans provide rapid, uniform heating suitable for maintaining the steady temperatures essential to perfect caramelization.

Understanding Regular Saucepans for Caramelizing

Regular saucepans, typically made from stainless steel or aluminum, offer even heat distribution essential for caramelizing sugar uniformly. Their compatibility with various stovetops makes them a versatile choice for achieving consistent caramel without hotspots.

While regular saucepans may heat more gradually compared to induction-ready pans, their thick bases help maintain steady temperatures, preventing burning during the delicate caramelization process. Understanding these characteristics ensures better control over sugar melting and color development.

Induction-Ready Saucepans: Features and Benefits

| Material Compatibility | Induction-ready saucepans feature magnetic stainless steel or iron bases that ensure even heat distribution essential for uniform caramelizing. |

| Heat Control | Precise temperature control with induction-ready saucepans prevents burning and allows gradual sugar melt, critical for perfect caramelization. |

| Energy Efficiency | Induction-ready saucepans heat faster and conserve energy better than regular saucepans, resulting in quicker caramelizing and consistent results. |

| Durability and Maintenance | These saucepans typically resist warping and have easy-to-clean surfaces, maintaining performance during frequent caramelizing tasks. |

Heat Distribution: Regular vs Induction-Ready Saucepans

Induction-ready saucepans offer precise and even heat distribution due to their magnetic base, which directly heats the cookware without energy loss. Regular saucepans often rely on a thicker metal base to distribute heat evenly but can have hot spots that affect caramelization consistency. The superior heat control of induction-ready pans ensures uniform caramelization, reducing the risk of burning sugar and enabling better flavor development.

Temperature Control and Responsiveness

Induction-ready saucepans offer precise temperature control, essential for the delicate caramelizing process, as they respond instantly to heat adjustments. Regular saucepans tend to have slower heat responsiveness, increasing the risk of uneven caramelization or burning.

- Temperature Stability - Induction-ready saucepans maintain consistent heat, preventing sugar from crystallizing prematurely.

- Heat Responsiveness - Regular saucepans take longer to adjust temperature changes, which can cause hot spots.

- Energy Efficiency - Induction-ready cookware heats more efficiently, reducing cooking time and improving caramel quality.

For perfect caramelizing, an induction-ready saucepan provides superior control and responsiveness compared to regular saucepans.

Material Matters: Stainless Steel, Aluminum, and More

Which saucepan material offers the best caramelizing results, regular or induction-ready? Stainless steel provides even heat distribution but can cause hotspots without a heavy base, while aluminum heats quickly and evenly, making it ideal for caramelizing. Induction-ready pans often combine layers of stainless steel and aluminum, optimizing heat control and preventing burning during the caramelization process.

Safety Considerations while Caramelizing

Regular saucepans provide even heat distribution, reducing the risk of hot spots that can cause sugar to burn during caramelizing, enhancing cooking safety. However, their slower heat response may require more attention to prevent overheating and accidents.

Induction-ready saucepans heat quickly and offer precise temperature control, minimizing the chance of caramelizing sugars beyond the desired stage and improving safety. Their stable base ensures firm contact with induction cooktops, reducing spill risks and enhancing user protection.

Caramelization Results: Texture and Flavor Comparison

Caramelizing in an induction-ready saucepan offers faster heat response, resulting in more consistent texture and richer flavor development compared to regular saucepans. Regular saucepans may produce uneven caramelization, causing variations in texture and slightly less intense flavor profiles.

- Heat Distribution - Induction-ready saucepans provide precise and even heat distribution, enhancing caramelization consistency.

- Texture Outcome - Faster heat response prevents graininess, yielding smoother caramel texture in induction models.

- Flavor Complexity - Consistent temperatures promote deeper Maillard reactions, intensifying flavor in induction pans.

Maintenance and Longevity of Each Pan Type

Regular saucepans often require more careful maintenance to prevent uneven heating and caramel buildup, which can shorten their lifespan. Induction-ready saucepans typically offer better heat distribution and durability, reducing the risk of warping and making them easier to clean after caramelizing.

- Maintenance demands - Regular pans need frequent seasoning and gentle cleaning to avoid caramel residue damage.

- Durability - Induction-ready pans resist warping due to consistent heat and high-quality materials.

- Cleaning ease - Non-stick induction pans simplify caramel residue removal, extending pan longevity.

Related Important Terms

Ferromagnetic base efficiency

An induction-ready saucepan with a ferromagnetic base offers superior efficiency for caramelizing due to rapid, even heat distribution and precise temperature control, minimizing hotspots and reducing the risk of burning sugar. In contrast, a regular saucepan without a ferromagnetic base may heat unevenly and respond slower to temperature adjustments, resulting in inconsistent caramelization.

Thermal response latency

Induction-ready saucepans offer faster thermal response latency compared to regular saucepans, ensuring rapid and precise temperature control essential for caramelizing sugar evenly without burning. Their magnetic base heats almost instantly, minimizing the risk of overheating and allowing for smoother, more consistent caramelization results.

Uniform browning differentials

Induction-ready saucepans offer superior heat distribution compared to regular saucepans, ensuring more uniform browning during caramelizing. This consistency prevents uneven caramelization and reduces the risk of hot spots that can cause burning or clumping.

Hotspot mitigation

Regular saucepans often develop hotspots during caramelizing, leading to uneven sugar melting and increased risk of burning. Induction-ready saucepans provide uniform heat distribution through magnetic bases, effectively mitigating hotspots and ensuring consistent caramelization.

Surface conductivity adaptation

Induction-ready saucepans feature magnetic stainless steel or ferromagnetic bases that ensure even heat distribution and optimal surface conductivity, crucial for precise caramelizing control. Regular saucepans, lacking this magnetic base, often deliver uneven heat, leading to inconsistent caramelization and potential burning.

Sugar crystallization control

Induction-ready saucepans offer superior temperature control compared to regular saucepans, enabling more precise management of heat crucial for preventing sugar crystallization during caramelizing. Their rapid and even heat distribution minimizes hotspots that can cause uneven caramelization and crystallization, ensuring a smooth and consistent caramel texture.

Induction coil compatibility

Induction-ready saucepans offer superior caramelizing performance due to their compatibility with induction coils, ensuring rapid and even heat distribution essential for precise sugar melting. Regular saucepans often lack this magnetic base, leading to inconsistent temperatures that can cause uneven caramelization or burning.

Copper core induction-compatibility

Copper core induction-ready saucepans provide superior heat conductivity and precise temperature control essential for caramelizing sugar evenly without burning. Regular saucepans often lack the rapid responsiveness and consistent heat distribution crucial for achieving the smooth, golden caramel texture.

Non-reactive layering

Induction-ready saucepans with non-reactive stainless steel layers provide even heat distribution and prevent caramelized sugar from reacting with the metal, ensuring consistent flavor and color during caramelizing. Regular saucepans often lack this specialized layering, which can lead to uneven heating and potential metallic taste in the caramel.

Regular saucepan vs Induction-ready saucepan for caramelizing. Infographic

cookingdiff.com

cookingdiff.com