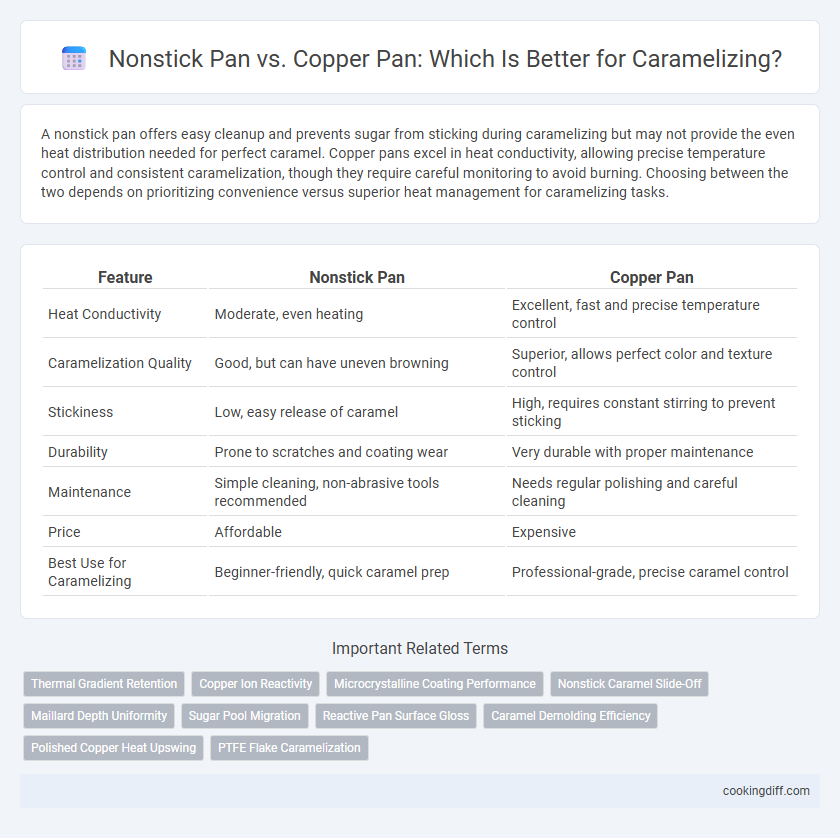

A nonstick pan offers easy cleanup and prevents sugar from sticking during caramelizing but may not provide the even heat distribution needed for perfect caramel. Copper pans excel in heat conductivity, allowing precise temperature control and consistent caramelization, though they require careful monitoring to avoid burning. Choosing between the two depends on prioritizing convenience versus superior heat management for caramelizing tasks.

Table of Comparison

| Feature | Nonstick Pan | Copper Pan |

|---|---|---|

| Heat Conductivity | Moderate, even heating | Excellent, fast and precise temperature control |

| Caramelization Quality | Good, but can have uneven browning | Superior, allows perfect color and texture control |

| Stickiness | Low, easy release of caramel | High, requires constant stirring to prevent sticking |

| Durability | Prone to scratches and coating wear | Very durable with proper maintenance |

| Maintenance | Simple cleaning, non-abrasive tools recommended | Needs regular polishing and careful cleaning |

| Price | Affordable | Expensive |

| Best Use for Caramelizing | Beginner-friendly, quick caramel prep | Professional-grade, precise caramel control |

Introduction to Caramelizing: The Importance of Pan Choice

Caramelizing requires precise temperature control to achieve the perfect golden-brown crust without burning the sugars. Nonstick pans offer even heat distribution and easy cleanup, making them ideal for beginners caramelizing delicate ingredients. Copper pans provide superior heat conductivity and responsiveness, allowing experienced cooks to adjust temperature quickly for optimal caramelization results.

Nonstick Pan Overview: Features and Benefits

Nonstick pans provide an even cooking surface that prevents sugar from sticking during caramelizing, making the process smoother and less messy. Their heat distribution is consistent enough for controlled caramelization, reducing the risk of burning sugar compared to some other materials.

- Nonstick coating - Reduces adherence of caramelized sugar, allowing easy deglazing and cleanup.

- Even heat distribution - Ensures uniform caramelization without hot spots that cause burning.

- Low maintenance - Requires less oil or butter to prevent sticking, promoting healthier cooking.

Nonstick pans offer a practical and efficient option for caramelizing sugar with minimal effort and cleanup.

Copper Pan Overview: Features and Benefits

Copper pans provide superior thermal conductivity that ensures even heat distribution, essential for precise caramelizing without burning. Their responsiveness to temperature changes allows for better control during the delicate caramelization process.

- Enhanced Heat Control - Copper pans quickly adjust to temperature changes, preventing sugar from scorching.

- Even Heat Distribution - The uniform heat minimizes hotspots, promoting consistent caramelization.

- Durability and Longevity - With proper maintenance, copper pans resist warping and maintain performance over time.

Heat Conductivity: Nonstick vs Copper Pans

Copper pans offer superior heat conductivity compared to nonstick pans, allowing for more precise temperature control essential for caramelizing sugar. Nonstick pans heat more slowly and less evenly, which can result in inconsistent caramelization.

- Copper pans - Conduct heat rapidly and evenly, preventing hot spots and enabling uniform caramelization.

- Nonstick pans - Distribute heat less efficiently, which may cause uneven caramel coloring and texture.

- Heat retention - Copper maintains consistent heat better, crucial for delicate caramel development.

Temperature Control for Perfect Caramelization

Nonstick pans offer consistent low to medium heat, reducing the risk of burning sugar during caramelizing due to their even temperature distribution. Copper pans provide superior temperature control, reacting quickly to changes in heat, which is essential for achieving precise caramelization.

Copper pans excel in temperature responsiveness, allowing chefs to adjust heat instantly and avoid overheating, a common issue with caramel. Their excellent conductivity prevents hot spots, ensuring uniform caramel color and flavor development. Nonstick pans, while convenient, may not achieve the same level of precision but remain effective for beginner caramelizing tasks.

Stickiness and Cleanup: Comparing Surfaces

Nonstick pans provide a smooth surface that significantly reduces stickiness when caramelizing sugar, making cleanup quick and effortless. Copper pans, while excellent for even heat distribution, often require careful monitoring to prevent sugar from sticking and burning, which can complicate cleaning. The nonstick coating offers a practical advantage for caramelizing tasks, minimizing residue and saving time during cleanup.

Flavor Development: How Pan Material Affects Caramelizing

How does the choice between a nonstick pan and a copper pan affect flavor development during caramelizing? Copper pans provide superior heat conductivity and precise temperature control, allowing sugars to caramelize evenly and develop deeper, more complex flavors. Nonstick pans, while easier to clean, often distribute heat less uniformly, potentially resulting in uneven caramelization and a milder flavor profile.

Durability and Maintenance: Long-Term Considerations

| Pan Type | Durability | Maintenance |

|---|---|---|

| Nonstick Pan | Nonstick coatings can degrade over time, especially with high heat used in caramelizing, reducing lifespan to about 2-5 years depending on usage. | Requires gentle cleaning with non-abrasive tools to preserve coating; avoid metal utensils and high heat to prolong usability. |

| Copper Pan | Highly durable with proper care, copper pans can last decades as the metal withstands high temperatures without damage during caramelizing. | Needs regular polishing to prevent patina and oxidation; occasional re-tinning or lining maintenance may be necessary for food safety and non-reactivity. |

Best Uses: When to Choose Nonstick or Copper for Caramelizing

Nonstick pans excel at caramelizing delicate sugars due to their smooth surface, which prevents sticking and allows for easy cleanup. They are ideal for beginners or quick caramel sauces requiring moderate heat.

Copper pans offer superior heat conductivity and precise temperature control, making them best suited for complex caramelization processes that demand even, consistent heat. Professional chefs often prefer copper when preparing caramel desserts or candy that require meticulous temperature adjustments.

Related Important Terms

Thermal Gradient Retention

Copper pans provide superior thermal gradient retention compared to nonstick pans, enabling more precise temperature control essential for even caramelization. Nonstick pans heat less evenly, often causing inconsistent caramelization due to their lower thermal conductivity and reduced ability to maintain stable heat gradients.

Copper Ion Reactivity

Copper pans excel in caramelizing due to their high thermal conductivity and efficient heat distribution, which prevents hot spots and allows precise temperature control essential for sugar caramelization. The copper ions released during cooking can interact with the caramel, subtly enhancing flavor complexity, whereas nonstick pans offer convenience but lack the reactive qualities that influence the caramel's chemical development.

Microcrystalline Coating Performance

Nonstick pans with microcrystalline coatings provide superior caramelizing performance due to their even heat distribution and reduced food adhesion, allowing precise temperature control and easy release of caramelized sugars. Copper pans offer excellent thermal conductivity but lack microcrystalline coatings, making them prone to uneven caramelization and increased risk of sugar sticking.

Nonstick Caramel Slide-Off

Nonstick pans excel in caramelizing due to their smooth surface that prevents sugar from sticking, allowing caramel to slide off effortlessly without burning. Unlike copper pans, nonstick cookware maintains even heat while minimizing the risk of crystallization, making it ideal for precise and mess-free caramel production.

Maillard Depth Uniformity

Nonstick pans offer consistent heat distribution that promotes uniform Maillard reaction during caramelizing, preventing hotspots that can cause uneven browning. Copper pans provide superior thermal conductivity for precise temperature control but may develop hot spots, resulting in variable Maillard depth and less uniform caramelization.

Sugar Pool Migration

Nonstick pans prevent sugar pool migration during caramelizing due to their smooth, non-porous surfaces that inhibit sugar crystals from sticking and spreading unevenly. Copper pans, with superior heat conductivity, provide precise temperature control but require constant stirring to avoid sugar pool migration and uneven caramelization.

Reactive Pan Surface Gloss

Nonstick pans provide a non-reactive, smooth surface that prevents sugar from sticking and burning, ensuring an even caramelization with a glossy finish. Copper pans, being reactive, can influence the color and flavor of the caramel due to metal-sugar interactions, often resulting in less consistent surface gloss compared to nonstick alternatives.

Caramel Demolding Efficiency

Nonstick pans excel in caramel demolding efficiency due to their smooth, non-porous surface that prevents caramel from sticking and allows easy release. Copper pans, while offering superior heat conductivity for even caramelization, often require more careful handling to prevent sticking, making demolding less efficient compared to nonstick options.

Polished Copper Heat Upswing

Polished copper pans offer superior heat conductivity and rapid heat upswing, making them ideal for precise caramelizing as they allow quick temperature adjustments to prevent burning sugar. Nonstick pans provide even heat distribution but lack the instantaneous heat response of copper, which may result in less control over caramel color and texture development.

Nonstick pan vs copper pan for caramelizing. Infographic

cookingdiff.com

cookingdiff.com