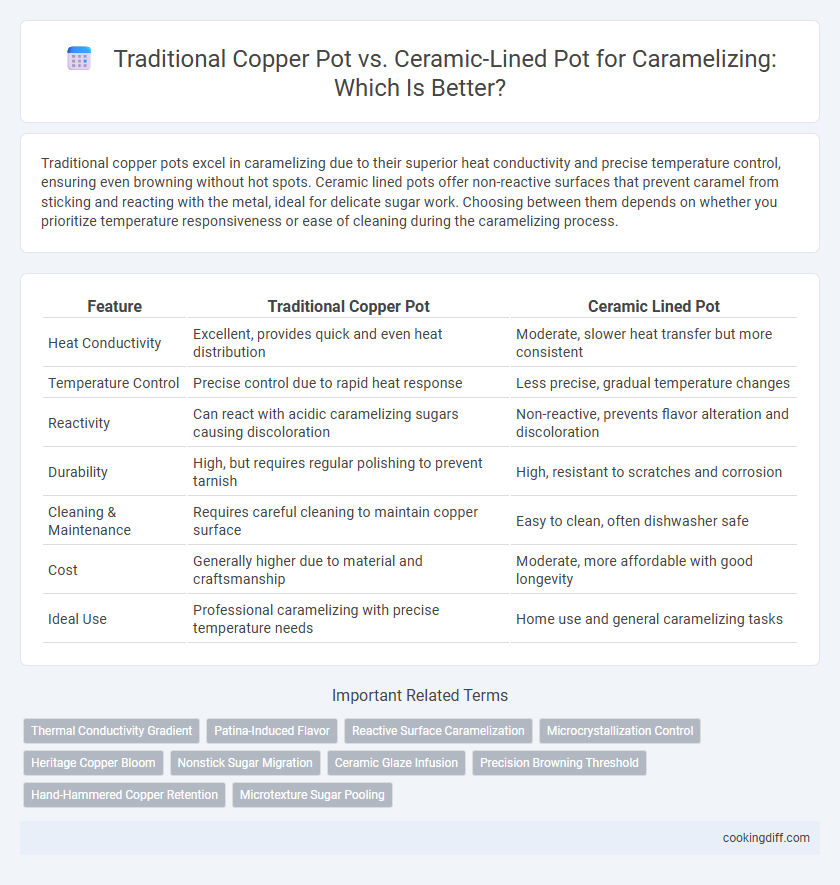

Traditional copper pots excel in caramelizing due to their superior heat conductivity and precise temperature control, ensuring even browning without hot spots. Ceramic lined pots offer non-reactive surfaces that prevent caramel from sticking and reacting with the metal, ideal for delicate sugar work. Choosing between them depends on whether you prioritize temperature responsiveness or ease of cleaning during the caramelizing process.

Table of Comparison

| Feature | Traditional Copper Pot | Ceramic Lined Pot |

|---|---|---|

| Heat Conductivity | Excellent, provides quick and even heat distribution | Moderate, slower heat transfer but more consistent |

| Temperature Control | Precise control due to rapid heat response | Less precise, gradual temperature changes |

| Reactivity | Can react with acidic caramelizing sugars causing discoloration | Non-reactive, prevents flavor alteration and discoloration |

| Durability | High, but requires regular polishing to prevent tarnish | High, resistant to scratches and corrosion |

| Cleaning & Maintenance | Requires careful cleaning to maintain copper surface | Easy to clean, often dishwasher safe |

| Cost | Generally higher due to material and craftsmanship | Moderate, more affordable with good longevity |

| Ideal Use | Professional caramelizing with precise temperature needs | Home use and general caramelizing tasks |

Introduction: Importance of Pot Selection in Caramelizing

Choosing the right pot is crucial for perfect caramelizing, as heat distribution directly affects sugar melting and color development. Traditional copper pots offer superior thermal conductivity, providing precise temperature control essential for preventing burning. Ceramic lined pots are valued for their non-reactive surfaces, ensuring pure caramel flavor without metallic interference.

Overview: Traditional Copper Pots in Caramelization

Traditional copper pots are highly valued for caramelizing due to their superior heat conductivity and precise temperature control. These characteristics ensure even caramelization without hot spots, which is crucial for achieving the perfect amber color and rich flavor.

- Excellent Heat Conductivity - Copper's high thermal conductivity allows rapid, uniform heat distribution essential for consistent caramelization.

- Precise Temperature Control - Copper pots enable chefs to maintain exact temperatures, preventing burning or crystallization during caramelization.

- Durability and Reactivity - While copper is reactive with acidic ingredients, traditional copper pots are often lined with tin or stainless steel to enhance durability and food safety.

Overview: Ceramic-Lined Pots and Their Features

What advantages do ceramic-lined pots offer for caramelizing compared to traditional copper pots? Ceramic-lined pots provide even heat distribution and resist sticking, making them ideal for controlled caramelization. Their non-reactive surface preserves the caramel's flavor, preventing metallic taste often associated with copper pots.

Heat Conductivity: Copper vs Ceramic-Lined Pots

Copper pots offer superior heat conductivity, allowing for precise temperature control essential in caramelizing sugar evenly and preventing burning. Ceramic-lined pots provide more gradual and even heat distribution but respond slower to temperature changes compared to copper.

- Copper Conductivity - Copper's high thermal conductivity (about 401 W/m*K) ensures rapid and uniform heat transfer ideal for caramelization processes.

- Ceramic Heat Retention - Ceramic linings retain heat longer but distribute it more slowly, which may result in less immediate temperature adjustments.

- Temperature Responsiveness - Copper pots respond nearly instantaneously to heat changes, enabling better control over sugar caramelization stages.

Choosing between copper and ceramic-lined pots depends on whether precise temperature control or even heat distribution is prioritized for caramelizing tasks.

Temperature Control and Responsiveness

Traditional copper pots offer superior temperature control and rapid responsiveness, allowing precise heat adjustments during the caramelizing process. Their excellent thermal conductivity helps prevent burning and ensures even caramelization.

Ceramic-lined pots retain heat more evenly but respond slower to temperature changes, making fine control more challenging when caramelizing sugar. These pots provide a gentler cooking environment, reducing the risk of hot spots and uneven caramelization.

Flavor Impact: Do Pot Materials Affect Taste?

Traditional copper pots provide superior heat conductivity, allowing precise temperature control essential for caramelizing sugar without burning, which enhances the caramel's rich flavor profile. Ceramic lined pots heat more slowly and evenly, reducing hot spots that can cause bitterness but may result in less nuanced caramelization.

Copper's reactive surface can subtly influence the chemical reactions during caramelizing, intensifying complex flavors and promoting a smoother texture. Ceramic lined pots offer a non-reactive environment, preserving the sugar's natural taste and preventing metallic flavors. Both materials significantly impact the final taste, with copper ideal for expert control and ceramic favored for gentle, even cooking.

Cleaning and Maintenance Considerations

Copper pots require careful cleaning to prevent tarnishing and maintain conductivity, often needing polishing to keep their shine. Ceramic lined pots offer easier maintenance as their non-porous surfaces resist caramel residue and simplify cleaning.

- Copper pots are prone to discoloration - They need regular polishing and gentle cleaning to avoid damage from acidic caramel.

- Ceramic surfaces are non-reactive - This property helps prevent stuck-on caramel and reduces the risk of scratches during cleaning.

- Copper requires seasoning over time - Proper upkeep ensures even heat distribution but increases cleaning diligence compared to ceramic.

Durability and Longevity Comparison

Traditional copper pots offer superior heat conductivity, allowing precise temperature control essential for caramelizing sugar without burning. However, copper requires regular polishing and maintenance to prevent tarnishing and corrosion, which can affect longevity.

Ceramic-lined pots provide excellent durability due to their non-reactive surfaces, resisting acid damage from caramelizing sugars and eliminating the need for frequent upkeep. The ceramic coating can wear or chip over time, potentially reducing the pot's lifespan compared to well-maintained copper vessels.

Safety and Reactivity with Sugar

| Pot Type | Safety | Reactivity with Sugar |

|---|---|---|

| Traditional Copper Pot | Requires regular polishing to avoid copper toxicity; can leach copper into food if not properly maintained. | High thermal conductivity provides even heating but can react with acidic sugars, risking off-flavors and discoloration. |

| Ceramic Lined Pot | Non-toxic and requires minimal maintenance; surface is resistant to scratching and chipping. | Non-reactive surface ensures pure caramel flavor without risk of chemical reactions with sugar. |

Related Important Terms

Thermal Conductivity Gradient

Traditional copper pots offer superior thermal conductivity with rapid, even heat distribution essential for precise caramelizing, preventing hotspots and burning. Ceramic-lined pots have a lower thermal conductivity gradient, resulting in slower heat transfer that can cause uneven caramelization and longer cooking times.

Patina-Induced Flavor

Traditional copper pots develop a unique patina that enhances caramelization by providing superior heat conduction and subtle flavor nuances, intensifying the complexity of the caramelized sugars. In contrast, ceramic-lined pots resist patina formation, offering a more neutral cooking surface that preserves the pure sweetness without additional flavor depth.

Reactive Surface Caramelization

Traditional copper pots excel in caramelizing due to their highly reactive surfaces, which promote even heat distribution and precise temperature control, minimizing the risk of scorching sugar. Ceramic-lined pots, being non-reactive, provide a more inert surface that prevents unwanted chemical reactions but may result in uneven heat and slower caramelization processes.

Microcrystallization Control

Traditional copper pots offer superior heat conductivity, allowing precise temperature control critical for microcrystallization during caramelizing, resulting in a smooth and consistent texture. Ceramic lined pots provide even heat distribution and prevent reactive metal interactions, but may require more careful temperature management to avoid uneven crystallization.

Heritage Copper Bloom

Heritage Copper Bloom's traditional copper pot offers superior heat conductivity, ensuring precise temperature control essential for perfect caramelization, unlike ceramic lined pots, which heat unevenly and risk scorching. The copper's natural responsiveness enables gradual caramel browning with minimal hot spots, preserving flavor integrity and achieving a smooth, rich caramel consistency.

Nonstick Sugar Migration

Traditional copper pots excel in heat conductivity, allowing even caramelization without hot spots, but they can promote sugar migration due to direct metal contact, potentially affecting the caramel's texture and color. Ceramic-lined pots offer a nonstick surface that minimizes sugar migration, preserving caramel integrity while providing a gentler heat distribution that reduces the risk of burning.

Ceramic Glaze Infusion

Ceramic lined pots with a ceramic glaze infusion provide superior heat retention and even temperature distribution essential for precise caramelizing, minimizing hot spots that can cause burning. Unlike traditional copper pots, the non-reactive ceramic surface prevents chemical interactions with sugar, ensuring a pure, consistent caramel flavor and easier cleanup.

Precision Browning Threshold

Traditional copper pots provide superior heat conductivity, enabling precise control over the browning threshold crucial for perfect caramelizing, while ceramic lined pots offer more gradual heat distribution but less responsiveness. The copper's rapid temperature adjustments prevent burning and promote uniform caramel color development, essential for achieving optimal flavor and texture.

Hand-Hammered Copper Retention

Hand-hammered copper pots excel in caramelizing due to their superior thermal conductivity and even heat distribution, allowing precise temperature control critical for achieving a perfect caramel. Ceramic-lined pots offer durability and non-reactivity but lack the heat retention and responsiveness that make traditional copper a preferred choice for expert caramelizing techniques.

Traditional copper pot vs ceramic lined pot for caramelizing. Infographic

cookingdiff.com

cookingdiff.com