When caramelizing, a classic sugar thermometer provides precise temperature readings by direct contact, ensuring accurate monitoring of sugar's critical stages. In contrast, an infrared laser thermometer measures surface temperature without contact, offering quick readings but potentially less accuracy due to reflections and uneven heating. Choosing between these tools depends on the need for precise caramel texture control versus convenience and speed in monitoring.

Table of Comparison

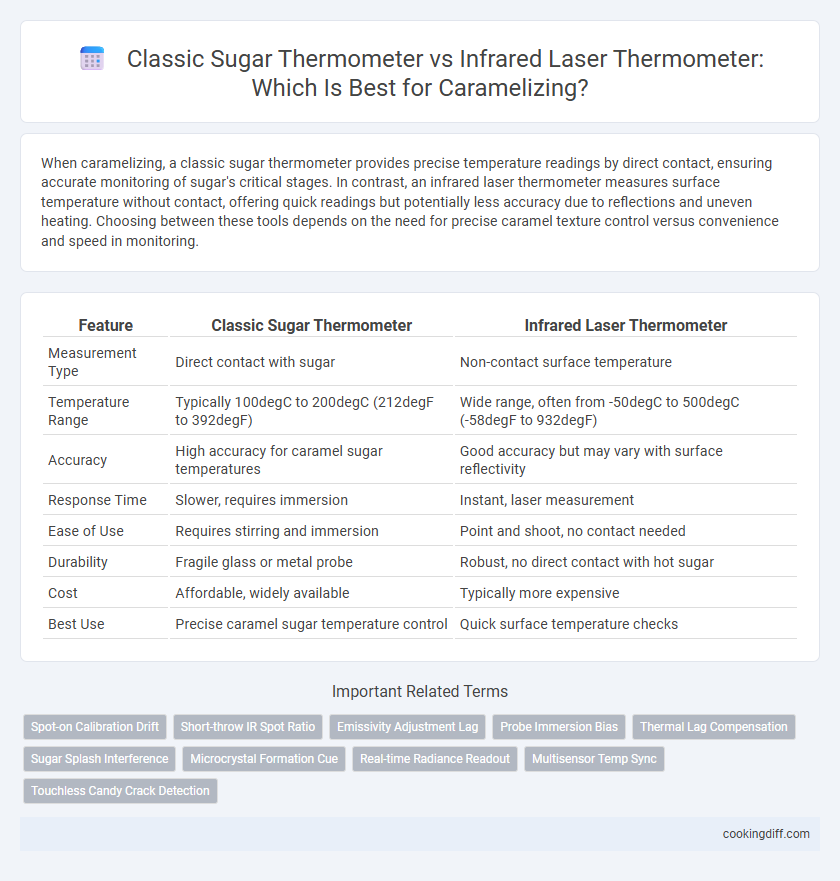

| Feature | Classic Sugar Thermometer | Infrared Laser Thermometer |

|---|---|---|

| Measurement Type | Direct contact with sugar | Non-contact surface temperature |

| Temperature Range | Typically 100degC to 200degC (212degF to 392degF) | Wide range, often from -50degC to 500degC (-58degF to 932degF) |

| Accuracy | High accuracy for caramel sugar temperatures | Good accuracy but may vary with surface reflectivity |

| Response Time | Slower, requires immersion | Instant, laser measurement |

| Ease of Use | Requires stirring and immersion | Point and shoot, no contact needed |

| Durability | Fragile glass or metal probe | Robust, no direct contact with hot sugar |

| Cost | Affordable, widely available | Typically more expensive |

| Best Use | Precise caramel sugar temperature control | Quick surface temperature checks |

Introduction: The Importance of Accurate Temperature in Caramelizing

How does precise temperature measurement impact the caramelizing process? Accurate temperature control is crucial for achieving the perfect caramel's rich flavor and texture, preventing burning or undercooking. Classic sugar thermometers provide direct contact readings for reliable sugar temperature, while infrared laser thermometers offer quick, non-contact surface measurements, each affecting caramel quality differently.

What is a Classic Sugar Thermometer?

A classic sugar thermometer is a weighted glass or metal device designed to measure the precise temperature of sugar syrups during caramelizing, ensuring the perfect consistency and color. It typically features a dial display calibrated between 100degF and 400degF, allowing cooks to monitor stages like soft ball, hard crack, and caramel. Unlike infrared laser thermometers, the classic sugar thermometer must be immersed in the liquid for accurate internal temperature readings essential for candy making.

How Infrared Laser Thermometers Work

| Infrared laser thermometers measure temperature by detecting the infrared radiation emitted from the surface of the sugar during caramelization. These devices use a laser to pinpoint the precise area, providing quick and non-contact temperature readings essential for achieving perfect caramel without disturbing the sugar's texture. This method is advantageous over classic sugar thermometers, which require direct contact and can influence the sugar's melting process. |

Precision and Accuracy: Classic vs. Infrared

The classic sugar thermometer offers precise temperature readings by direct contact with the caramel, ensuring accurate measurements critical for achieving the perfect caramelization stage. Infrared laser thermometers provide quick, non-contact readings but may be less accurate due to surface reflections and emissivity variations.

Classic sugar thermometers excel in accuracy by measuring the actual temperature of the sugar mixture, reducing the risk of under or over caramelizing. Infrared thermometers are valued for convenience and speed but require calibration and skill to interpret readings reliably. For consistent caramel results, the classic sugar thermometer remains the preferred tool for professionals and home cooks alike.

Ease of Use in the Caramelizing Process

Classic sugar thermometers provide direct contact temperature readings essential for precise caramelizing, while infrared laser thermometers offer non-contact convenience, allowing quick surface temperature checks. The ease of use depends on your preference for hands-on accuracy versus rapid, hygienic measurements.

- Classic sugar thermometer - Requires immersion in the sugar mixture, offering accurate, real-time temperature but demands careful handling.

- Infrared laser thermometer - Measures surface temperature instantly without touching the caramel, reducing contamination risk.

- User preference - Caramelizing precision benefits from the tactile feedback of classic thermometers, while infrared devices simplify monitoring.

Choosing between them optimizes ease of use based on whether direct contact or quick, non-invasive readings suit your caramelizing technique.

Response Time: Real-Time Temperature Readings Compared

Infrared laser thermometers provide near-instantaneous temperature readings, allowing for precise control during the caramelizing process. Classic sugar thermometers have a slower response time due to the need for direct contact with the sugar mixture.

- Infrared Thermometer Response Time - Measures surface temperature instantly without touching the caramel.

- Classic Sugar Thermometer Lag - Requires immersion and equilibration time, causing delayed readings.

- Impact on Caramelizing Accuracy - Faster response of infrared devices helps prevent burning by offering real-time adjustments.

Safety Considerations for Each Thermometer

Classic sugar thermometers require direct contact with the hot sugar, which increases the risk of burns or spills, necessitating careful handling and heat-resistant gloves. Their glass construction can break if dropped, posing additional safety hazards during caramelizing.

Infrared laser thermometers measure temperature from a distance, reducing burn risk and allowing safer monitoring of hot sugar without contact. However, they can be less accurate on reflective or uneven surfaces, requiring cautious interpretation to avoid undercooking or overheating caramel.

Cleaning and Maintenance Differences

Classic sugar thermometers require frequent calibration and careful cleaning to remove sticky caramel residues, which can affect accuracy and sensor longevity. Their metal probes must be thoroughly washed and dried after each use to prevent sugar buildup and corrosion.

Infrared laser thermometers offer a contactless measurement method, eliminating direct exposure to sticky sugar and simplifying maintenance. Cleaning involves just wiping the lens with a soft cloth, reducing the risk of damage and ensuring consistent performance over time.

Cost and Durability Analysis

Classic sugar thermometers are generally more affordable and built to withstand high heat exposure, making them durable tools for caramelizing. Infrared laser thermometers, while pricier, offer non-contact temperature readings but may require careful handling and calibration to maintain accuracy over time.

- Cost Efficiency - Classic sugar thermometers often cost less upfront, providing a budget-friendly option for consistent caramelizing tasks.

- Durability - Sugar thermometers are designed to endure the direct heat of boiling sugar without damage or wear.

- Maintenance - Infrared laser thermometers need regular calibration and careful use to ensure reliable performance, impacting long-term durability.

Related Important Terms

Spot-on Calibration Drift

Classic sugar thermometers provide consistent spot-on calibration essential for precise caramelization by measuring the sugar's temperature directly in the pot, ensuring accurate sugar stages. Infrared laser thermometers, while quick and non-contact, often experience calibration drift due to surface reflectivity and ambient conditions, making them less reliable for exact caramelization control.

Short-throw IR Spot Ratio

Classic sugar thermometers provide direct contact measurements crucial for accurate caramelizing at precise temperatures around 170degC (338degF), while infrared laser thermometers with short-throw IR spot ratios enable non-contact surface temperature readings, minimizing contamination risk and offering rapid feedback. The high precision of short-throw IR spot ratios allows targeting small caramelizing zones, ensuring optimal heat control and preventing sugar burning.

Emissivity Adjustment Lag

Classic sugar thermometers provide direct temperature readings essential for precise caramelizing but suffer from slower response times and potential heat loss during measurement. Infrared laser thermometers offer rapid, non-contact temperature detection yet require precise emissivity adjustment to avoid lag and inaccurate readings on glossy caramel surfaces.

Probe Immersion Bias

Classic sugar thermometers require probe immersion to measure the temperature within the caramel, providing more accurate readings by directly detecting the liquid's heat but risking bias if the probe touches the container. Infrared laser thermometers avoid contact and quickly measure surface temperature but may produce inaccurate results due to surface reflections and inability to assess internal caramel temperature, leading to probe immersion bias in critical caramelizing processes.

Thermal Lag Compensation

Classic sugar thermometers provide direct contact measurements essential for precise caramelizing, but their thermal lag may cause delayed temperature readings affecting sugar's critical stages. Infrared laser thermometers offer rapid, non-contact temperature detection with minimal thermal lag, enabling more accurate monitoring of the caramelization process's exact temperature.

Sugar Splash Interference

Classic sugar thermometers provide direct contact measurement crucial for accurate caramelizing temperatures but are susceptible to sugar splash interference causing potential damage and inaccurate readings. Infrared laser thermometers offer non-contact temperature readings that avoid sugar splash issues but may struggle with reflective surfaces or uneven heat distribution during caramelizing.

Microcrystal Formation Cue

Classic sugar thermometers provide precise temperature readings critical for controlling microcrystal formation during caramelizing, ensuring smooth texture and preventing graininess. Infrared laser thermometers, while convenient for surface temperature measurement, may lack accuracy in detecting micro-level temperature changes needed to monitor the caramel's internal crystal structure.

Real-time Radiance Readout

Classic sugar thermometers provide precise temperature measurements essential for caramelizing sugars between 320degF and 350degF, ensuring accurate control of the Maillard reaction. Infrared laser thermometers offer real-time radiance readouts by detecting surface temperature instantly without contact, enhancing efficiency but requiring calibration for reflective sugar surfaces.

Multisensor Temp Sync

The Classic sugar thermometer provides precise, direct contact measurements essential for accurate caramelizing, while the infrared laser thermometer offers quick, non-contact surface readings. Multisensor Temp Sync technology integrates both methods, delivering synchronized data to optimize caramelization temperature control and prevent sugar burning.

Classic sugar thermometer vs infrared laser thermometer for caramelizing. Infographic

cookingdiff.com

cookingdiff.com