Traditional caramelization for browning involves applying direct heat to sugar, causing it to melt and turn golden brown through a natural Maillard reaction, which enhances flavor and color. Reverse caramelization uses a controlled cooling process after heating, allowing sugars to crystallize slowly, resulting in a distinct texture and a more nuanced, deeper caramel flavor. Both methods impact the final taste and appearance of caramelized products, with traditional caramelization delivering a classic crisp finish while reverse caramelization provides a softer, richer profile.

Table of Comparison

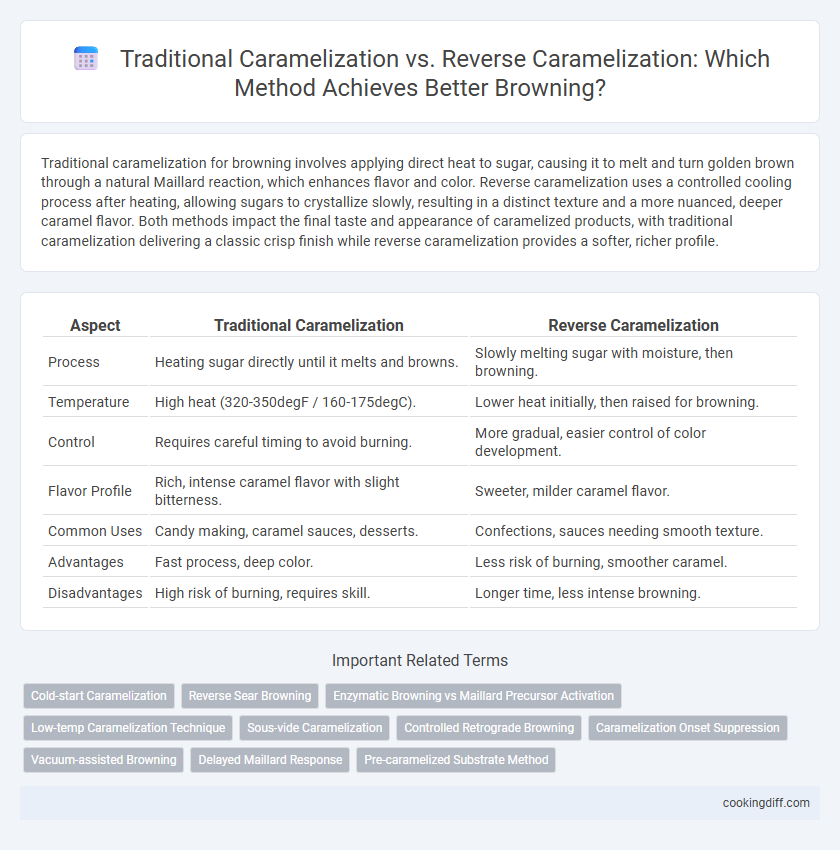

| Aspect | Traditional Caramelization | Reverse Caramelization |

|---|---|---|

| Process | Heating sugar directly until it melts and browns. | Slowly melting sugar with moisture, then browning. |

| Temperature | High heat (320-350degF / 160-175degC). | Lower heat initially, then raised for browning. |

| Control | Requires careful timing to avoid burning. | More gradual, easier control of color development. |

| Flavor Profile | Rich, intense caramel flavor with slight bitterness. | Sweeter, milder caramel flavor. |

| Common Uses | Candy making, caramel sauces, desserts. | Confections, sauces needing smooth texture. |

| Advantages | Fast process, deep color. | Less risk of burning, smoother caramel. |

| Disadvantages | High risk of burning, requires skill. | Longer time, less intense browning. |

Introduction to Caramelization Methods

What distinguishes traditional caramelization from reverse caramelization in culinary applications? Traditional caramelization involves heating sugar directly to high temperatures to achieve browning and flavor development. Reverse caramelization starts with sugar dissolved in water, slowly heated to control browning and enhance flavor complexity.

Defining Traditional Caramelization

Traditional caramelization is the process of heating sugar directly until it melts and turns a rich amber color, producing complex flavors. This method relies on high temperatures to initiate the Maillard reaction along with sugar breakdown for browning.

- Direct Heat Application - Sugar is cooked at temperatures typically between 320degF to 350degF to achieve melting and color development.

- Flavor Profile Development - Produces deep, nutty, and slightly bitter notes characteristic of classic caramel taste.

- Usage in Cooking - Commonly used in making sauces, candies, and desserts where sugar browning is essential for flavor and appearance.

Exploring Reverse Caramelization Technique

Reverse caramelization involves heating sugar with liquid before reducing it, allowing for more controlled browning and deeper flavor development compared to traditional caramelization. This technique minimizes the risk of burning and creates a smoother, less bitter caramel with enhanced aromatic complexity. Chefs often prefer reverse caramelization for delicate desserts and sauces due to its precision and consistency in color and taste.

Chemical Reactions Behind Browning

Traditional caramelization involves heating sugars directly to initiate Maillard reactions and sugar pyrolysis, resulting in complex brown pigments and rich flavors. Reverse caramelization, however, starts with caramelized sugar solutions that react with amino acids under milder conditions, producing distinct browning and flavor profiles.

The chemical reactions behind traditional caramelization primarily include thermal decomposition and polymerization of sugars, generating volatile compounds and melanoidins. In reverse caramelization, amino acids interact with caramelized intermediates through Maillard pathways, enhancing color intensity and aromatic complexity. Both methods utilize controlled heat to manipulate sugar structure and protein interactions, influencing texture and taste in culinary applications.

Key Differences in Flavor Profiles

Traditional caramelization involves heating sugar until it melts and turns golden brown, producing rich, deep flavors with hints of toffee and nuttiness. This method emphasizes the Maillard reaction, enhancing complexity and a slightly bitter undertone.

Reverse caramelization starts with browning the ingredients first, then slowly incorporating sugar, resulting in a milder, sweeter flavor profile with less bitterness. This technique preserves subtle fruity notes and creates a more delicate, nuanced sweetness compared to traditional caramelization.

Impact on Texture and Appearance

| Method | Texture Impact | Appearance Impact |

|---|---|---|

| Traditional Caramelization | Creates a crispy, crunchy surface due to direct exposure to high heat, enhancing the structural integrity of the caramelized layer. | Produces a deep amber color with glossy sheen, resulting from Maillard reactions and sugar breakdown at elevated temperatures. |

| Reverse Caramelization | Yields a softer, tender texture as gradual heating prevents excessive hardening, preserving moisture within the caramelized product. | Generates a lighter, golden-brown hue with a matte finish, reflecting slower sugar transformation and reduced browning intensity. |

Temperature and Timing Comparisons

Traditional caramelization requires higher temperatures (320degF to 350degF) and shorter cooking times to quickly achieve a deep brown color. Reverse caramelization uses lower temperatures over extended periods, allowing for more controlled browning and flavor development.

- Higher Temperature in Traditional Method - Speeds up the Maillard reaction, producing rich caramel notes rapidly.

- Lower Temperature in Reverse Method - Prevents burning, resulting in a more uniform and delicate caramel color.

- Timing Differences - Traditional caramelization takes minutes, while reverse caramelization can take 15-30 minutes for optimal browning.

Best Uses and Applications in Cooking

Traditional caramelization involves heating sugar until it melts and turns a deep amber color, ideal for creating rich sauces, desserts, and glazes with complex flavor profiles. Reverse caramelization, which starts with browning ingredients before adding sugar, is best for savory dishes like caramelized onions or roasted vegetables, enhancing umami and depth without overpowering sweetness. Each method offers distinct applications, with traditional caramelization excelling in sweet preparations and reverse caramelization enhancing savory recipes.

Pros and Cons of Each Method

Traditional caramelization involves heating sugar or food directly over high heat, resulting in a rich, deep brown color and complex flavors. This method quickly develops a robust, intense caramel flavor but carries a higher risk of burning and uneven browning.

Reverse caramelization heats food at lower temperatures with indirect heat before finishing with high heat for browning, offering better control and more even color development. While it reduces the chance of burning, the flavor profile may be less intense and the process takes longer compared to traditional caramelization.

Related Important Terms

Cold-start Caramelization

Cold-start caramelization in reverse caramelization initiates browning by slowly heating sugar from a low temperature, allowing for precise control over color and flavor development compared to traditional caramelization, which rapidly melts sugar at high heat, often leading to uneven browning and burnt notes. This technique enhances the depth and complexity of caramel flavors while minimizing bitterness, making it ideal for delicate culinary applications.

Reverse Sear Browning

Reverse sear browning utilizes reverse caramelization by slowly cooking meat at low temperatures before searing it at high heat, enhancing Maillard reactions without overcooking the interior. This method achieves a more evenly browned crust and juicier texture compared to traditional caramelization, which applies direct high heat from the start.

Enzymatic Browning vs Maillard Precursor Activation

Traditional caramelization relies on the Maillard reaction, where reducing sugars react with amino acids to produce complex flavors and brown pigments through Maillard precursor activation, intensifying savory and nutty notes. Reverse caramelization emphasizes enzymatic browning by activating polyphenol oxidase enzymes that oxidize phenolic compounds, resulting in natural browning primarily seen in fruits and vegetables before heat is applied.

Low-temp Caramelization Technique

Traditional caramelization relies on high heat to break down sugars quickly, producing deep, complex flavors and rich brown hues, while reverse caramelization uses a low-temperature technique that gently melts sugars, allowing for more controlled browning and enhanced sweetness without the risk of burning. This low-temp caramelization method preserves delicate aromas and creates a smoother, more nuanced caramel profile ideal for sensitive ingredients and slow-cooked dishes.

Sous-vide Caramelization

Sous-vide caramelization utilizes controlled low-temperature cooking to achieve even browning and enhanced flavor development by maintaining precise heat and moisture levels, contrasting with traditional high-heat caramelization that can cause uneven browning and burnt edges. This reverse caramelization method allows gradual Maillard reactions and sugar conversion, resulting in a tender texture with rich caramel notes often unattainable through conventional direct heat techniques.

Controlled Retrograde Browning

Traditional caramelization relies on direct heat to brown sugars, often leading to uneven color and flavor development, while reverse caramelization utilizes lower temperatures with prolonged cooking to achieve controlled retrograde browning, enhancing flavor complexity and uniformity. Controlled retrograde browning minimizes burnt notes by carefully managing the Maillard reactions and sugar breakdown, resulting in a richer, more balanced caramel profile.

Caramelization Onset Suppression

Traditional caramelization initiates browning through high heat that triggers sugar breakdown and Maillard reactions, while reverse caramelization suppresses this onset by applying controlled low heat or moisture to delay sugar decomposition, enhancing flavor development and color uniformity. This suppression technique minimizes premature browning and bitterness, optimizing texture and sweetness in culinary applications.

Vacuum-assisted Browning

Traditional caramelization relies on high heat to break down sugars and develop complex flavors and a deep brown color, often risking uneven cooking and burnt notes. Reverse caramelization, especially when combined with vacuum-assisted techniques, allows browning at lower temperatures with controlled oxygen levels, enhancing flavor development and color uniformity while preserving delicate textures.

Delayed Maillard Response

Traditional caramelization induces early sugar browning through direct heat, triggering Maillard reactions quickly, whereas reverse caramelization delays the Maillard response by initially applying lower temperatures to promote gradual enzyme activity before achieving complex browning. This method enhances flavor depth and color uniformity, optimizing the balance between sugar caramelization and protein-sugar interactions for superior browning results.

Traditional Caramelization vs Reverse Caramelization for Browning Infographic

cookingdiff.com

cookingdiff.com