A carbon steel pan offers superior heat retention and even distribution, making it ideal for achieving the perfect caramelization on pet food or treats. While a saute pan provides a larger surface area and higher sides to prevent spills, it may not deliver the same intense, consistent heat needed for deep, golden caramelization. Opting for carbon steel ensures better control over temperature and more flavorful, evenly caramelized results.

Table of Comparison

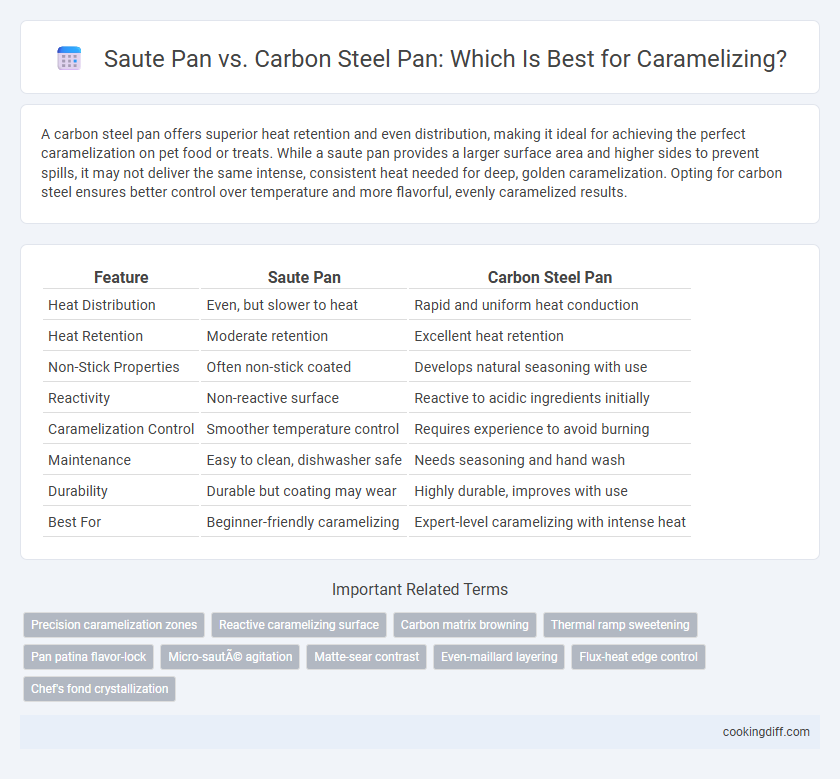

| Feature | Saute Pan | Carbon Steel Pan |

|---|---|---|

| Heat Distribution | Even, but slower to heat | Rapid and uniform heat conduction |

| Heat Retention | Moderate retention | Excellent heat retention |

| Non-Stick Properties | Often non-stick coated | Develops natural seasoning with use |

| Reactivity | Non-reactive surface | Reactive to acidic ingredients initially |

| Caramelization Control | Smoother temperature control | Requires experience to avoid burning |

| Maintenance | Easy to clean, dishwasher safe | Needs seasoning and hand wash |

| Durability | Durable but coating may wear | Highly durable, improves with use |

| Best For | Beginner-friendly caramelizing | Expert-level caramelizing with intense heat |

Introduction: Choosing the Best Pan for Caramelizing

Choosing the best pan for caramelizing significantly affects flavor development and texture. Saute pans offer even heat distribution and a wide surface, ideal for consistent caramelization.

Carbon steel pans heat quickly and respond well to temperature changes, providing excellent control for delicate caramelizing tasks. Their natural non-stick surface improves with seasoning, preventing sugar from sticking and burning. Both pan types enhance the caramelizing process, but the choice depends on heat control preferences and the specific dish's demands.

What Is Caramelization?

Caramelization is the chemical process where sugar molecules break down under heat, creating complex flavors and a rich brown color. This reaction typically occurs between 320degF and 350degF, enhancing the taste and aroma of various foods.

- Saute Pan - Distributes heat evenly but can retain moisture, potentially slowing caramelization.

- Carbon Steel Pan - Heats quickly and achieves higher temperatures, ideal for faster caramelization.

- What Is Caramelization? - It is the browning of sugar through heat, producing sweet, nutty, and complex flavor compounds.

Overview of Sauté Pans

What makes saute pans suitable for caramelizing compared to carbon steel pans? Saute pans have a wider, flat bottom and flared sides that allow for even heat distribution and easy stirring, essential for achieving consistent caramelization. Their design also prevents food from sticking, making them ideal for cooking sugars evenly without burning.

Overview of Carbon Steel Pans

Carbon steel pans offer excellent heat retention and responsiveness, making them ideal for evenly caramelizing sugars and vegetables. Their naturally non-stick surface improves with seasoning, enhancing both flavor development and ease of use compared to standard saute pans.

- High Heat Conductivity - Carbon steel pans quickly reach and maintain high temperatures essential for perfect caramelization.

- Durable and Lightweight - These pans combine strength with ease of handling for precise control over cooking.

- Seasoning Benefits - Repeated use creates a natural non-stick layer that enhances browning and flavor.

Carbon steel pans provide superior performance for caramelizing tasks compared to traditional saute pans.

Heat Distribution: Sauté Pan vs Carbon Steel Pan

Carbon steel pans offer superior heat distribution, allowing for more even caramelization without hotspots that can cause burning. Saute pans typically have thicker bases which retain heat longer but may not distribute it as evenly, leading to uneven caramel color development. This precise temperature control in carbon steel pans is essential for achieving consistent, rich caramelization in cooking.

Responsiveness and Temperature Control

A carbon steel pan offers superior responsiveness and precise temperature control essential for achieving perfect caramelization without burning. In contrast, a saute pan retains heat longer but responds slower to temperature changes, which can make fine adjustments more challenging during the caramelizing process.

- Carbon Steel Pan responds quickly - It heats up and cools down rapidly, allowing for better control over the caramelization temperature.

- Saute Pan retains heat longer - Its thicker base distributes heat evenly but delays temperature adjustments, risking overcooking.

- Temperature precision favors carbon steel - Fine-tuning heat is crucial for caramelization, and carbon steel's responsiveness supports optimal sugar browning.

Nonstick Qualities and Food Release

| Pan Type | Nonstick Qualities | Food Release for Caramelizing |

|---|---|---|

| Saute Pan | Typically features a nonstick coating allowing easy cleanup and reduced food sticking during caramelization | Ensures smooth food release, preventing burnt sugar from adhering and promoting even browning |

| Carbon Steel Pan | Develops a natural seasoning layer over time providing moderate nonstick properties when properly maintained | Food release improves with use, although initial caramelizing may require more attention to prevent sticking |

Maintenance and Durability

Carbon steel pans require regular seasoning to maintain their non-stick properties and prevent rust, demanding consistent maintenance compared to most saute pans. Saute pans often feature non-stick coatings that simplify cleaning but may degrade faster under high heat, impacting long-term durability.

Carbon steel pans offer superior durability and can last decades with proper care, developing a natural patina that enhances flavor and performance over time. Saute pans are typically more resistant to corrosion but may need replacement sooner due to coating wear or structural warping.

Best Uses: When to Choose Sauté or Carbon Steel for Caramelizing

A carbon steel pan is ideal for caramelizing due to its superior heat retention and even heat distribution, which promotes consistent browning of sugars. A saute pan, with its higher sides, is better suited for caramelizing larger quantities or dishes requiring deglazing with liquids. For precise caramelization control, especially in professional kitchens, the carbon steel pan offers enhanced responsiveness to temperature changes.

Related Important Terms

Precision caramelization zones

A carbon steel pan offers superior precision in caramelization zones due to its rapid, even heat distribution and excellent temperature control, allowing for uniform browning of sugars without hotspots. In contrast, a saute pan's thicker base may retain heat longer but often results in less precise temperature adjustments, potentially causing uneven caramelization or burning.

Reactive caramelizing surface

Carbon steel pans offer a reactive surface that enhances caramelization by allowing better heat control and promoting even browning due to their rapid responsiveness to temperature changes. In contrast, non-reactive saute pans, typically coated with stainless steel or non-stick materials, provide a more inert surface that may slow the development of caramelization flavors but prevent food from sticking.

Carbon matrix browning

Carbon steel pans excel at caramelizing due to their ability to reach high, even temperatures that promote carbon matrix browning, enhancing flavor complexity and richness. Unlike saute pans, carbon steel's reactive surface aids in developing deep mahogany crusts by facilitating precise temperature control and efficient heat transfer.

Thermal ramp sweetening

Carbon steel pans offer superior thermal ramping for caramelizing due to their excellent heat conductivity and rapid temperature response, enabling precise control over Maillard reactions and sugar caramelization. Saute pans, often featuring thicker bases, heat more slowly and can lead to uneven browning, making carbon steel the preferred choice for achieving uniform, sweet caramelized layers.

Pan patina flavor-lock

A carbon steel pan develops a natural patina that enhances flavor-locking during caramelizing, providing a rich, complex taste compared to the typically smoother surface of a saute pan. The seasoned carbon steel's ability to retain heat evenly promotes superior browning and deep caramel flavor development.

Micro-sauté agitation

A carbon steel pan offers superior heat retention and even distribution, enhancing micro-saute agitation for more consistent caramelization of sugars and proteins. In contrast, a saute pan's typically heavier design may limit the subtle tossing motion needed to achieve a perfectly caramelized surface without burning.

Matte-sear contrast

A carbon steel pan excels in caramelizing due to its superior heat retention and ability to develop a natural non-stick patina, creating a matte-sear contrast that enhances the golden-brown crust on sugars and proteins. Saute pans, often made of stainless steel with polished surfaces, tend to produce a shinier sear but lack the even heat distribution and patina formation of carbon steel, resulting in less pronounced caramelization depth.

Even-maillard layering

A carbon steel pan offers superior heat retention and distribution compared to a saute pan, enabling more consistent even-Maillard layering essential for perfect caramelizing. Its ability to maintain high temperatures ensures uniform browning and enhances the development of complex caramel flavors.

Flux-heat edge control

A carbon steel pan offers superior flux-heat edge control during caramelizing due to its excellent heat conductivity and responsiveness, allowing precise temperature adjustments that prevent burning and uneven browning. In contrast, a saute pan may retain heat less uniformly, making it harder to manage the delicate caramelization process with consistent edge heat distribution.

Sauté pan vs carbon steel pan for caramelizing. Infographic

cookingdiff.com

cookingdiff.com