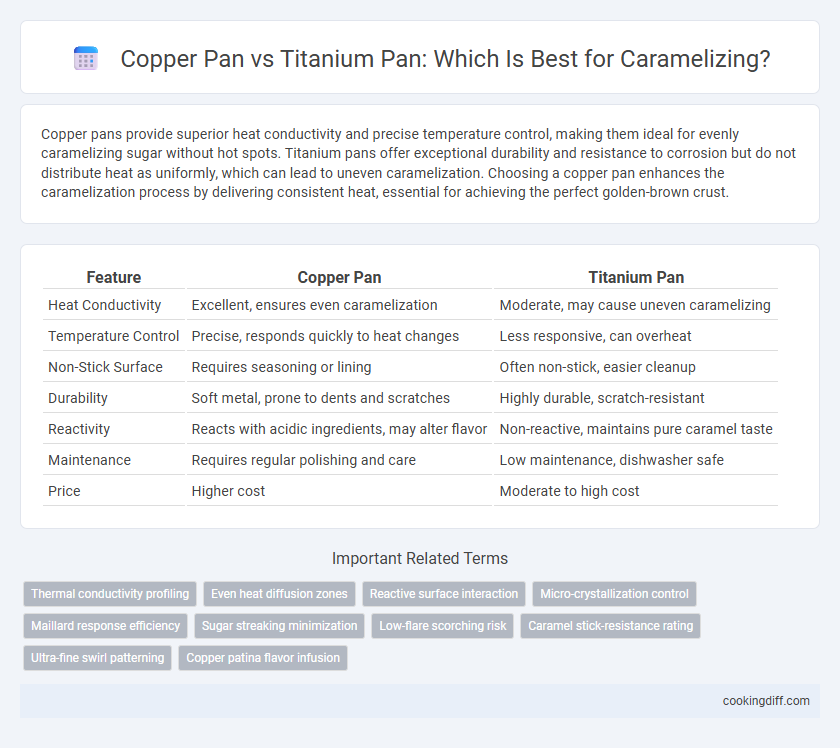

Copper pans provide superior heat conductivity and precise temperature control, making them ideal for evenly caramelizing sugar without hot spots. Titanium pans offer exceptional durability and resistance to corrosion but do not distribute heat as uniformly, which can lead to uneven caramelization. Choosing a copper pan enhances the caramelization process by delivering consistent heat, essential for achieving the perfect golden-brown crust.

Table of Comparison

| Feature | Copper Pan | Titanium Pan |

|---|---|---|

| Heat Conductivity | Excellent, ensures even caramelization | Moderate, may cause uneven caramelizing |

| Temperature Control | Precise, responds quickly to heat changes | Less responsive, can overheat |

| Non-Stick Surface | Requires seasoning or lining | Often non-stick, easier cleanup |

| Durability | Soft metal, prone to dents and scratches | Highly durable, scratch-resistant |

| Reactivity | Reacts with acidic ingredients, may alter flavor | Non-reactive, maintains pure caramel taste |

| Maintenance | Requires regular polishing and care | Low maintenance, dishwasher safe |

| Price | Higher cost | Moderate to high cost |

Introduction to Caramelizing: Why Pan Choice Matters

Caramelizing requires precise temperature control to achieve the perfect Maillard reaction without burning the sugar. The choice between a copper pan and a titanium pan significantly impacts heat conductivity and evenness, influencing the caramelization process.

- Copper pans provide superior heat conductivity - They allow rapid and even heat distribution, minimizing hot spots and preventing sugar burn.

- Titanium pans offer durability and non-reactivity - They resist corrosion and do not affect the flavor of caramelized sugar.

- Thermal responsiveness differs greatly - Copper pans react faster to temperature changes, enabling better control during caramelization compared to titanium pans.

Choosing the right pan enhances the texture and flavor of caramelized dishes by ensuring steady and even heat application.

Copper Pans: Properties and Benefits for Caramelizing

Copper pans offer superior heat conductivity and precise temperature control, making them ideal for caramelizing sugar evenly without scorching. Their quick response to temperature changes prevents burning and promotes a smooth, consistent caramel texture.

- Excellent Heat Conductivity - Copper conducts heat much faster than titanium, allowing for rapid and even heating essential for caramelization.

- Precise Temperature Control - Copper pans respond instantly to heat adjustments, helping maintain the perfect caramelizing temperature.

- Prevents Hot Spots - The even heat distribution of copper eliminates hot spots, reducing the risk of burnt or uneven caramel.

Titanium Pans: Features and Suitability for Caramelizing

Titanium pans offer exceptional durability and resist corrosion, making them a reliable choice for caramelizing due to their non-reactive surface. Their lightweight nature and even heat distribution help prevent hotspots that can burn sugar during the caramelization process.

The non-stick qualities of titanium pans reduce the risk of caramel sticking and burning, ensuring a smoother cooking experience. Titanium's quick heating properties allow precise temperature control, crucial for achieving perfect caramel without crystallization. These features make titanium pans particularly suitable for professional chefs and home cooks striving for consistent caramel results.

Heat Conductivity: Copper vs Titanium for Consistent Caramelization

Copper pans offer superior heat conductivity, ensuring even and rapid heat distribution crucial for consistent caramelization. Titanium pans, although durable, have lower thermal conductivity, which can lead to uneven heating and hotspots during the caramelizing process.

- Copper's high thermal conductivity - Allows precise temperature control for smooth caramelization without burning.

- Titanium's lower heat transfer - May cause inconsistent caramel texture due to uneven heat distribution.

- Copper pan responsiveness - Quickly adapts to temperature changes, essential for delicate caramelizing stages.

Temperature Control: Precision with Copper or Titanium?

Copper pans offer superior temperature control with rapid heat responsiveness, allowing precise caramelizing without overheating. This quick adjustment minimizes burning risks, ensuring even caramelization of sugars.

Titanium pans provide excellent heat retention but slower temperature changes, which may challenge delicate caramelizing processes. Their durability suits high-heat cooking but demands careful monitoring to avoid scorching caramel.

Reactivity with Sugar: Material Impact on Caramel Flavor

How does the reactivity of copper and titanium pans affect the caramelization process? Copper pans offer superior heat conductivity, allowing for even caramelization and enhanced flavor development, as copper reacts minimally with sugar. Titanium pans, being non-reactive, prevent metallic taste interference but may require more precise heat control to avoid uneven caramelization.

Ease of Cleaning: Maintenance for Caramel Residue

Copper pans offer superior heat conductivity, allowing for even caramelization but can be challenging to clean due to caramel's tendency to stick and harden. Titanium pans are non-reactive and generally easier to clean because their non-stick surface prevents caramel residue from adhering strongly. Regular soaking and gentle scrubbing maintain both types, but titanium pans demand less intensive maintenance for caramel residue removal.

Durability and Longevity: Copper vs Titanium Under High Heat

Copper pans excel in heat conductivity, allowing precise temperature control essential for caramelizing, but they can be prone to discoloration and require regular polishing to maintain their appearance. Over time, exposure to high heat may cause copper to warp or tarnish, potentially reducing its durability.

Titanium pans offer exceptional strength and resistance to warping under intense heat, ensuring long-lasting performance during caramelization. Their sturdy construction minimizes wear and maintains surface integrity, making them highly durable for frequent high-heat cooking tasks.

Cost Comparison: Investing in the Right Pan for Caramelizing

| Pan Type | Material Cost | Durability | Suitability for Caramelizing |

|---|---|---|---|

| Copper Pan | Typically $150 to $400 | High; excellent heat conductivity, requires regular polishing | Ideal for precise temperature control during caramelization; prevents burning |

| Titanium Pan | Generally $50 to $200 | Very high; scratch-resistant, low maintenance | Good heat distribution but less precise than copper, can cause uneven caramelization |

Related Important Terms

Thermal conductivity profiling

Copper pans exhibit superior thermal conductivity, approximately 401 W/m*K, enabling rapid and even heat distribution crucial for precise caramelizing and preventing hot spots. Titanium pans, with significantly lower thermal conductivity around 17 W/m*K, tend to heat unevenly, increasing the risk of caramel scorching and inconsistent texture development.

Even heat diffusion zones

Copper pans offer superior even heat diffusion with rapid temperature adjustments, preventing hot spots essential for precise caramelizing control. Titanium pans, while durable and non-reactive, have less efficient heat conduction, potentially leading to uneven caramelization zones.

Reactive surface interaction

Copper pans provide superior temperature control and even heat distribution, allowing precise caramelization without hot spots, but their reactive surface can interact with acidic sugars, potentially altering flavor. Titanium pans are non-reactive and maintain flavor integrity during caramelizing, yet may deliver less uniform heat compared to copper, affecting the consistency of caramel development.

Micro-crystallization control

Copper pans offer superior heat conductivity and precise temperature control essential for micro-crystallization during caramelizing, resulting in smooth, evenly textured caramel. Titanium pans, while durable and non-reactive, lack the fine temperature responsiveness needed to prevent premature crystallization and achieve optimal caramel consistency.

Maillard response efficiency

Copper pans offer superior heat conductivity and precise temperature control, enhancing the Maillard reaction efficiency during caramelizing by promoting even browning and preventing hot spots. Titanium pans, while durable and resistant to corrosion, provide less thermal responsiveness, which may result in uneven caramelization and less consistent Maillard reaction outcomes.

Sugar streaking minimization

Copper pans provide superior heat conductivity and precise temperature control, significantly reducing sugar streaking during caramelizing by ensuring even caramel formation. Titanium pans, while durable and non-reactive, often distribute heat less evenly, increasing the risk of uneven caramelization and visible sugar streaks.

Low-flare scorching risk

Copper pans provide superior heat conductivity and precise temperature control, significantly reducing the risk of low-flare scorching during caramelizing compared to titanium pans. Titanium pans, while durable, heat less evenly and are more prone to hot spots that can cause uneven caramelization and burning.

Caramel stick-resistance rating

Copper pans offer superior heat conductivity and precise temperature control, making them highly effective for caramelizing without burning or sticking, while titanium pans feature excellent non-stick properties and durability but may not distribute heat as evenly, sometimes causing uneven caramel stick resistance. For optimal caramel stick resistance, copper pans are often preferred by chefs for their ability to maintain consistent heat and reduce caramel adhesion.

Ultra-fine swirl patterning

Copper pans provide superior thermal conductivity essential for precise temperature control during caramelizing, enabling ultra-fine swirl patterning with consistent heat distribution. Titanium pans, while durable and corrosion-resistant, lack the same level of heat responsiveness, often resulting in less defined patterns and uneven caramelization.

Copper pan vs titanium pan for caramelizing. Infographic

cookingdiff.com

cookingdiff.com