Stovetop caramelizing offers direct heat that requires constant attention to avoid burning, making precise temperature control challenging. Sous vide caramelizing allows for exact temperature regulation by immersing food in a water bath, ensuring even caramelization without overheating. This method reduces the risk of scorching and delivers consistent, controlled caramel flavor.

Table of Comparison

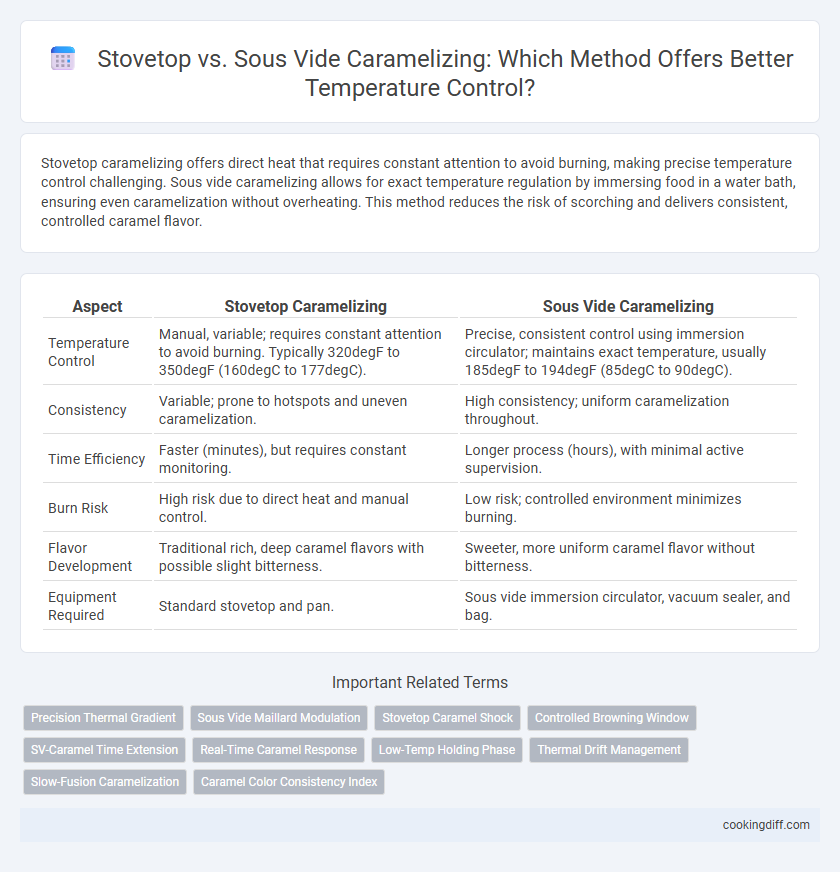

| Aspect | Stovetop Caramelizing | Sous Vide Caramelizing |

|---|---|---|

| Temperature Control | Manual, variable; requires constant attention to avoid burning. Typically 320degF to 350degF (160degC to 177degC). | Precise, consistent control using immersion circulator; maintains exact temperature, usually 185degF to 194degF (85degC to 90degC). |

| Consistency | Variable; prone to hotspots and uneven caramelization. | High consistency; uniform caramelization throughout. |

| Time Efficiency | Faster (minutes), but requires constant monitoring. | Longer process (hours), with minimal active supervision. |

| Burn Risk | High risk due to direct heat and manual control. | Low risk; controlled environment minimizes burning. |

| Flavor Development | Traditional rich, deep caramel flavors with possible slight bitterness. | Sweeter, more uniform caramel flavor without bitterness. |

| Equipment Required | Standard stovetop and pan. | Sous vide immersion circulator, vacuum sealer, and bag. |

Introduction to Caramelization Techniques

Stovetop caramelizing relies on direct heat, often making precise temperature control challenging and increasing the risk of burning sugar. Sous vide caramelizing uses water bath immersion with exact temperature regulation, allowing consistent and gentle caramelization over time. This temperature control in sous vide enhances flavor development and prevents bitterness compared to traditional stovetop methods.

Basics of Stovetop Caramelizing

Stovetop caramelizing involves cooking sugar directly over heat, requiring constant attention to prevent burning. Mastery of temperature control is essential to achieve the desired golden-brown color without bitterness.

- Direct Heat Application - Sugar is heated directly on the stovetop, making temperature fluctuations common and challenging.

- Visual Cues for Control - Caramelization progress is monitored by changes in color rather than precise temperature measurements.

- Rapid Temperature Changes - Heat adjustments affect caramelization speed dramatically, demanding quick responses from the cook.

Maintaining consistent heat and close observation are basic skills required for effective stovetop caramelizing.

How Sous Vide Caramelizing Works

Sous vide caramelizing uses precise temperature control by immersing food in a water bath set to a specific temperature, typically between 130degF and 185degF. This method prevents burning, allowing sugars in the food to caramelize evenly over an extended period.

Unlike stovetop caramelizing, which relies on direct high heat and constant monitoring, sous vide caramelizing maintains consistent thermal conditions, ensuring uniform caramelization. The controlled environment enhances flavor development and preserves texture by avoiding temperature spikes that can scorch the sugar.

Temperature Control in Stovetop Methods

Stovetop caramelizing requires precise temperature control to prevent burning, typically maintained between 320degF and 350degF. Achieving this involves constant monitoring and adjusting the heat to ensure the sugar melts evenly and develops a rich amber color.

Unlike sous vide caramelizing, stovetop methods demand more skill to avoid hot spots and temperature fluctuations that can lead to uneven caramelization. Using a heavy-bottomed pan can help distribute heat more uniformly, enhancing control over the caramelizing process.

Precision of Sous Vide Temperature Regulation

Sous vide caramelizing offers unmatched temperature precision, maintaining a consistent heat level to prevent burning. In contrast, stovetop caramelizing relies on manual heat adjustments, increasing the risk of uneven caramelization.

- Exact Temperature Control - Sous vide devices regulate heat within a fraction of a degree, ensuring perfect caramelization every time.

- Reduced Risk of Overcooking - Consistent low temperatures minimize the chance of caramel burning or crystallizing.

- Reproducible Results - Precise temperature settings allow for easy replication of caramelizing processes across batches.

Flavor Development: Stovetop vs. Sous Vide

Stovetop caramelizing allows for rapid temperature changes, creating intense, deep flavors through direct heat and Maillard reactions. In contrast, sous vide caramelizing offers precise temperature control, ensuring even caramelization without burning, which enhances subtle, complex flavor notes.

Stovetop caramelizing excels at developing bold, robust flavors due to its high heat and quick caramel formation. Sous vide caramelizing, however, maintains consistent temperatures that encourage uniform sugar breakdown and nuanced flavor profiles. This method reduces the risk of bitterness and produces a smoother, more refined caramel taste.

Texture Outcomes: Comparing Both Methods

How does temperature control affect the texture outcomes in stovetop caramelizing versus sous vide caramelizing? Stovetop caramelizing often results in a more variable texture due to fluctuating temperatures, leading to crispy or slightly burnt edges. Sous vide caramelizing offers precise temperature control, producing consistently smooth and evenly caramelized textures without the risk of overcooking.

Equipment Requirements and Accessibility

| Stovetop Caramelizing | Requires standard kitchen equipment such as a heavy-bottomed pan and a reliable stove, making it highly accessible for most home cooks. Temperature control depends on manual adjustments, which can lead to inconsistent caramelization if not monitored closely. |

| Sous Vide Caramelizing | Demands specialized equipment including an immersion circulator and vacuum sealer, which may be cost-prohibitive for casual cooks. Offers precise temperature control through water bath settings, ensuring consistent and even caramelization results. |

Pros and Cons: Stovetop vs. Sous Vide Caramelizing

Stovetop caramelizing offers rapid temperature changes but requires constant monitoring to prevent burning, whereas sous vide caramelizing provides precise temperature control, ensuring even caramel formation with minimal risk of scorching. Each method balances control and convenience differently, influencing texture and flavor outcomes.

- Stovetop caramelizing offers quick heat application - It allows faster browning but risks uneven caramelization due to fluctuating temperatures.

- Sous vide caramelizing ensures stable temperature - This method maintains consistent heat, resulting in uniform caramel color and flavor development.

- Stovetop requires active attention - Constant stirring and monitoring are necessary to avoid burning, unlike sous vide's hands-off process.

Related Important Terms

Precision Thermal Gradient

Stovetop caramelizing relies on direct heat, often resulting in uneven temperature distribution and higher risk of hot spots that can burn sugar due to lack of precise thermal gradient control. Sous vide caramelizing employs precise temperature regulation through water bath immersion, ensuring a consistent and controlled thermal gradient that prevents scorching and achieves uniform caramelization.

Sous Vide Maillard Modulation

Sous vide caramelizing offers precise temperature control, enabling exact Maillard reaction modulation by maintaining consistent heat, unlike stovetop methods where temperature fluctuations can lead to uneven caramelization and potential burning. This precision optimizes flavor development and texture, making sous vide ideal for delicate caramelizing processes.

Stovetop Caramel Shock

Stovetop caramelizing often suffers from caramel shock, a sudden temperature drop that causes sugar crystallization and grainy texture, due to inconsistent heat control. Sous vide caramelizing, by precisely maintaining low and stable temperatures, minimizes caramel shock, resulting in a smooth and evenly caramelized product.

Controlled Browning Window

Stovetop caramelizing often struggles with maintaining a controlled browning window due to direct high heat and fluctuating temperatures, increasing the risk of burning sugar. Sous vide caramelizing offers precise temperature control by using a water bath, ensuring consistent caramelization within the optimal 160-180degC range for perfect browning without scorching.

SV-Caramel Time Extension

Sous vide caramelizing offers precise temperature control, extending caramelization time without risking burning, unlike stovetop methods that rely on direct heat and often cause uneven cooking. This controlled environment allows sugars to slowly develop deeper flavors and rich color while maintaining consistent texture.

Real-Time Caramel Response

Stovetop caramelizing offers immediate temperature changes, allowing for real-time control but requires constant attention to prevent burning, whereas sous vide caramelizing maintains a precise, stable temperature, enabling consistent caramel response without active monitoring. Real-time caramel response is more dynamic with stovetop methods, but sous vide ensures uniform caramelization through controlled thermal immersion.

Low-Temp Holding Phase

Stovetop caramelizing often involves direct high heat, making precise low-temperature holding phases challenging and increasing the risk of burning sugar. Sous vide caramelizing allows exceptional temperature control by maintaining a steady low-temp environment, ensuring gradual sugar transformation and consistent caramelization without overheating.

Thermal Drift Management

Stovetop caramelizing often suffers from thermal drift due to uneven heat distribution and manual temperature adjustments, leading to inconsistent browning and flavor development. Sous vide caramelizing offers precise temperature control and superior thermal drift management by maintaining a stable water bath environment, ensuring uniform caramelization and optimal flavor extraction.

Slow-Fusion Caramelization

Stovetop caramelizing often involves high, fluctuating temperatures that can lead to uneven browning and burnt sugar, whereas sous vide caramelizing uses precise, controlled low temperatures, enabling slow-fusion caramelization that enhances flavor development and uniform texture without scorching. This method maintains consistent heat below 180degF, optimizing Maillard reactions and preserving delicate caramel notes for superior culinary results.

Stovetop Caramelizing vs Sous Vide Caramelizing for temperature control. Infographic

cookingdiff.com

cookingdiff.com