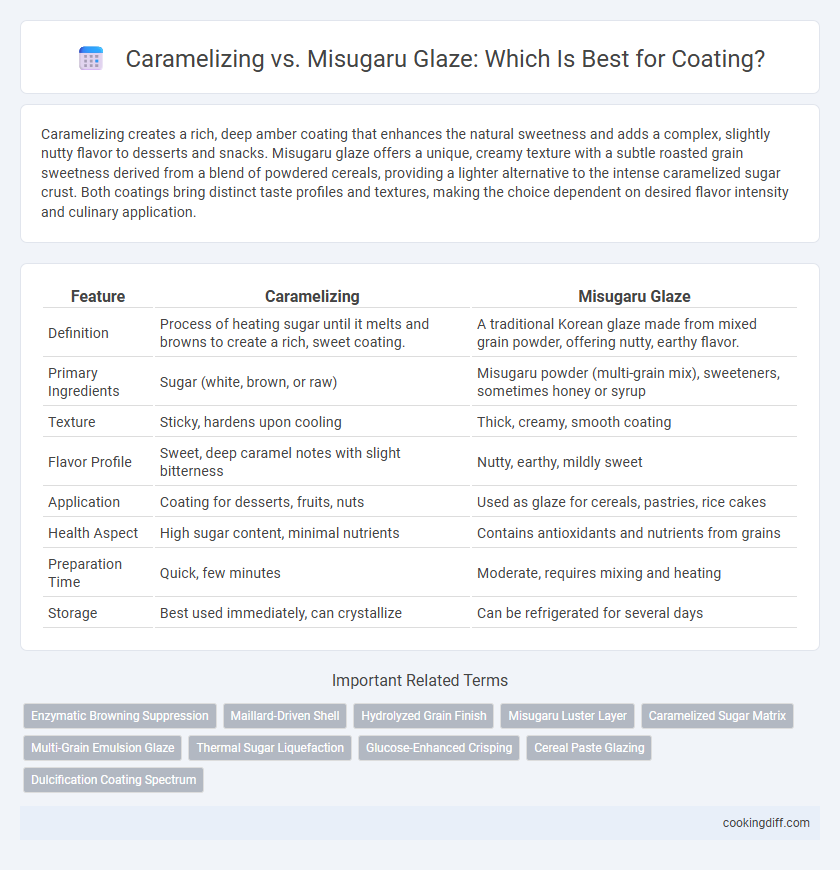

Caramelizing creates a rich, deep amber coating that enhances the natural sweetness and adds a complex, slightly nutty flavor to desserts and snacks. Misugaru glaze offers a unique, creamy texture with a subtle roasted grain sweetness derived from a blend of powdered cereals, providing a lighter alternative to the intense caramelized sugar crust. Both coatings bring distinct taste profiles and textures, making the choice dependent on desired flavor intensity and culinary application.

Table of Comparison

| Feature | Caramelizing | Misugaru Glaze |

|---|---|---|

| Definition | Process of heating sugar until it melts and browns to create a rich, sweet coating. | A traditional Korean glaze made from mixed grain powder, offering nutty, earthy flavor. |

| Primary Ingredients | Sugar (white, brown, or raw) | Misugaru powder (multi-grain mix), sweeteners, sometimes honey or syrup |

| Texture | Sticky, hardens upon cooling | Thick, creamy, smooth coating |

| Flavor Profile | Sweet, deep caramel notes with slight bitterness | Nutty, earthy, mildly sweet |

| Application | Coating for desserts, fruits, nuts | Used as glaze for cereals, pastries, rice cakes |

| Health Aspect | High sugar content, minimal nutrients | Contains antioxidants and nutrients from grains |

| Preparation Time | Quick, few minutes | Moderate, requires mixing and heating |

| Storage | Best used immediately, can crystallize | Can be refrigerated for several days |

Understanding Caramelizing: Definition and Process

Caramelizing is the process of cooking sugar until it melts and turns into a rich, brown syrup that enhances flavor and texture. This technique differs significantly from applying a Misugaru glaze, which uses a mixture of roasted grain powders for a nutty, less sweet coating.

- Caramelizing Definition - It involves heating sugar to approximately 340degF (170degC) to initiate a chemical reaction called the Maillard reaction, producing complex flavors and a golden-brown color.

- Process Control - Temperature regulation and timing are critical to prevent burning and achieve the desired caramel consistency and taste.

- Misugaru Glaze Contrast - Unlike caramelizing, Misugaru glaze offers a grain-based coating with subtle sweetness and a powdery texture, making it a contrasting choice for surface finishing.

Introducing Misugaru Glaze: Ingredients and Origins

Misugaru glaze originates from Korea, traditionally made by mixing finely ground roasted grains such as black soybeans, barley, and brown rice into a sweet, nutty paste. This unique glaze provides a chewy texture and a depth of flavor distinct from typical caramel coatings.

Caramelizing involves heating sugar to create a sweet and glossy coating, offering a rich, buttery taste and crunchy texture. Misugaru glaze, in contrast, emphasizes natural roasted grain flavors and a wholesome sweetness, often preferred for healthier dessert options. Both methods enhance the surface of foods but differ significantly in ingredients, flavor profile, and cultural background.

Key Differences Between Caramelizing and Misugaru Glaze

| Aspect | Caramelizing | Misugaru Glaze |

|---|---|---|

| Primary Process | Heating sugar to create a deep, rich brown flavor and glossy coating. | Mixing multi-grain powder (typically barley, millet, black bean) with sweeteners for a textured glaze. |

| Flavor Profile | Sweet with bitter undertones due to sugar's Maillard reaction. | Nutty, earthy, and mildly sweet from natural grains and subtle sugars. |

| Texture and Appearance | Smooth, thick, and shiny coating that hardens upon cooling. | Granular, creamy texture with a matte finish and slight graininess. |

Flavor Profile: Caramelizing vs Misugaru Glaze

Caramelizing enhances ingredients by developing rich, deep flavors through the Maillard reaction, resulting in a sweet, nutty, and slightly bitter profile. It creates a glossy, amber coating that intensifies the natural sugars and adds complexity to dishes.

Misugaru glaze, made from Korean roasted grain powder, offers a unique earthy sweetness with subtle roasted and nutty undertones. Its flavor profile is milder and less intense than caramel, providing a delicate, smooth coating that complements rather than dominates the base ingredient.

Texture and Mouthfeel Comparison

How do the texture and mouthfeel of caramelizing compare to those of Misugaru glaze when used for coating? Caramelizing creates a crisp, crunchy outer layer that adds a satisfying crunch to the coated item. Misugaru glaze offers a smooth, creamy texture with a slightly gritty mouthfeel from ground grains, resulting in a unique, multi-dimensional coating experience.

Best Uses and Recipe Applications

Caramelizing is ideal for creating deep, rich flavors and a glossy finish on fruits and desserts, enhancing sweetness through heat-induced sugar transformation. Misugaru glaze, made from roasted multi-grain powders, offers a nutty, complex texture perfect for health-centric coatings and traditional Korean treats.

- Caramelizing - Best used for desserts like caramel apples, creme brulee, and glazed nuts where a crunchy, sweet crust is desired.

- Misugaru Glaze - Ideal for coating rice cakes, mochi, and smoothies to add a natural, grainy sweetness with nutritional benefits.

- Recipe Applications - Caramelizing applies heat directly to sugar, perfect for quick, intense coatings, while misugaru glaze suits recipes requiring a smooth, wholesome finish without high heat.

Caramelizing Techniques: Tips for Success

Caramelizing involves heating sugar to a specific temperature to create a rich, golden-brown coating that adds deep flavor and texture to dishes. Mastering temperature control and timing is crucial to prevent burning and achieve the perfect balance of sweetness and bitterness. Using a heavy-bottomed pan and stirring constantly are essential techniques to ensure even caramelization and a smooth, glossy glaze.

Crafting the Perfect Misugaru Glaze

Caramelizing involves heating sugar to create a rich, amber-colored coating that adds deep, complex flavors to desserts and confections. Misugaru glaze, derived from a traditional Korean multigrain powder, offers a unique nutty sweetness and smooth texture ideal for coating baked goods.

Crafting the perfect misugaru glaze requires precise blending of roasted grains with honey or rice syrup to achieve optimal viscosity and flavor balance. This glaze provides a natural alternative to caramelizing, enhancing texture while delivering a distinctive, healthful sweetness.

Health Considerations: Nutritional Differences

Caramelizing sugar for coating primarily increases calorie content due to added sugars, while Misugaru glaze, made from mixed grains, provides more dietary fiber and essential nutrients. Health considerations favor Misugaru glaze for those seeking lower glycemic impact and enhanced nutritional benefits.

- Higher Sugar Content - Caramelized coatings have elevated levels of simple sugars that can spike blood glucose.

- Increased Fiber - Misugaru glaze contains whole grain powders that contribute to daily fiber intake.

- Micronutrient Density - Mixed grains in Misugaru offer vitamins and minerals absent in caramelized sugar coatings.

Choosing Misugaru glaze supports better blood sugar management and improved nutrient intake compared to traditional caramelizing techniques.

Related Important Terms

Enzymatic Browning Suppression

Caramelizing sugar creates a rich, deep brown coating through controlled heat-induced Maillard reactions, while Misugaru glaze leverages natural enzymes to suppress enzymatic browning, preserving the glaze's lighter color and fresh flavor. This enzymatic inhibition in Misugaru enhances visual appeal and nutritional retention compared to traditional caramelizing methods.

Maillard-Driven Shell

Caramelizing creates a Maillard-driven shell through sugar pyrolysis, yielding a complex, nutty crust essential for rich flavor profiles in coatings. In contrast, Misugaru glaze relies on a roasted grain blend that imparts a mild sweetness and textured finish without the deep Maillard reaction characteristic of caramelization.

Hydrolyzed Grain Finish

Caramelizing creates a rich, deep flavor and glossy finish by heating sugars to a precise temperature, enhancing the appearance and texture of the coating. In contrast, Misugaru glaze, enriched with hydrolyzed grain finish, offers a unique combination of complex malted grain notes and a smooth, slightly nutty texture that improves adhesion and moisture retention.

Misugaru Luster Layer

The Misugaru luster layer creates a distinct, matte finish with a nutty aroma that penetrates deeply, unlike caramelizing which forms a glossy, brittle coating through sugar oxidation. This Misugaru glaze provides a richer texture and enhanced flavor profile, offering more complex sweetness and a velvety mouthfeel compared to traditional caramelized surfaces.

Caramelized Sugar Matrix

Caramelizing creates a complex sugar matrix formed by the thermal breakdown of sucrose, resulting in deep flavor development and a rich, glossy coating ideal for enhancing textures and taste in confections. Unlike Misugaru glaze, which relies on powdered grain blends for a nutty profile, the caramelized sugar matrix provides a distinctive, crisp caramel coating that intensifies sweetness with nuanced bitterness.

Multi-Grain Emulsion Glaze

Caramelizing creates a rich, deep flavor by heating sugars until they brown, enhancing the texture and sweetness in coatings, while Misugaru glaze, made from finely ground multi-grain powder, offers a nutty, aromatic profile combined with a smooth, emulsified consistency. Multi-Grain Emulsion Glaze excels by blending the complex flavors of various grains into a stable, glossy coating that balances sweetness and earthiness without the risk of burning common in caramelizing.

Thermal Sugar Liquefaction

Caramelizing involves thermal sugar liquefaction where sucrose undergoes controlled heating, resulting in complex flavor development and a glossy, amber glaze ideal for coating. Misugaru glaze, by contrast, relies on a mixture of finely ground grains with minimal sugar liquefaction, offering a matte finish and nutty profile without the deep Maillard-induced caramel notes.

Glucose-Enhanced Crisping

Caramelizing creates a rich, golden-brown coating through the Maillard reaction, enhancing glucose levels that contribute to a crisp texture, whereas Misugaru glaze relies on a multi-grain suspension offering a smoother, less crunchy surface. Glucose-enhanced crisping in caramelizing provides superior crunch and flavor complexity compared to the subtle, nutty finish typical of Misugaru glazes.

Cereal Paste Glazing

Caramelizing creates a rich, golden-brown coating through sugar's Maillard reaction, ideal for crisp cereal paste glazing that enhances texture and flavor depth. Misugaru glaze, made from a multigrain powder blend, offers a subtle, nutty sweetness and smoother finish, providing a healthier alternative for cereal paste coatings.

Caramelizing vs Misugaru Glaze for coating. Infographic

cookingdiff.com

cookingdiff.com