A combi oven provides precise humidity and temperature control, resulting in evenly caramelized pet treats without burning or drying out. Regular ovens often lack this level of control, which can lead to inconsistent caramelization and uneven texture. Using a combi oven enhances safety while delivering professional-quality caramelized results for pet snacks.

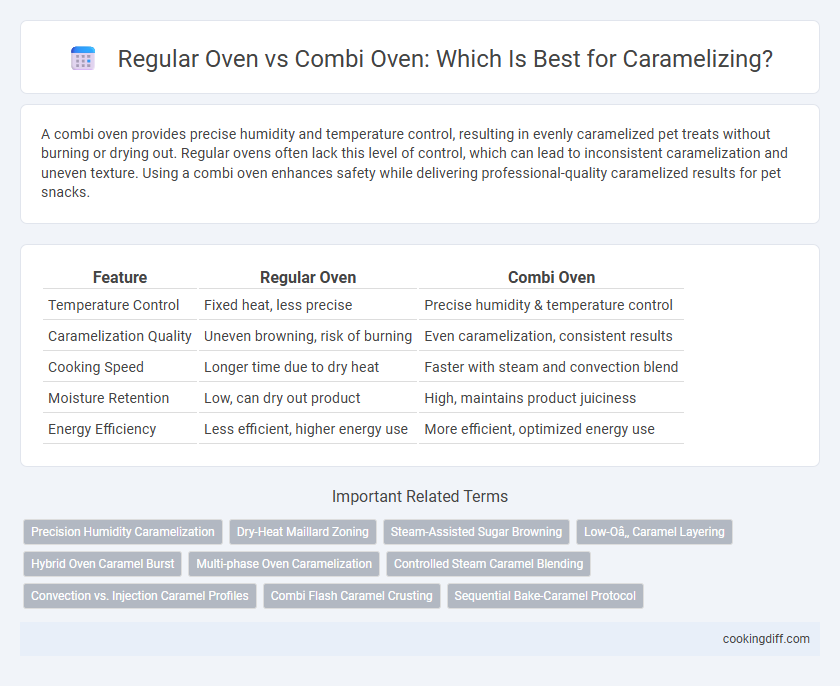

Table of Comparison

| Feature | Regular Oven | Combi Oven |

|---|---|---|

| Temperature Control | Fixed heat, less precise | Precise humidity & temperature control |

| Caramelization Quality | Uneven browning, risk of burning | Even caramelization, consistent results |

| Cooking Speed | Longer time due to dry heat | Faster with steam and convection blend |

| Moisture Retention | Low, can dry out product | High, maintains product juiciness |

| Energy Efficiency | Less efficient, higher energy use | More efficient, optimized energy use |

Key Differences Between Regular and Combi Ovens for Caramelizing

Caramelizing in a regular oven relies primarily on dry heat, which may lead to uneven browning and longer cooking times. Combi ovens combine steam and convection heat, allowing for more precise control over temperature and moisture levels, resulting in consistent caramelization.

- Heat Source - Regular ovens use only dry heat, while combi ovens utilize both steam and convection heat for optimal caramelizing.

- Temperature Control - Combi ovens offer precise temperature and humidity adjustments, improving caramelization quality compared to regular ovens.

- Cooking Speed - Combi ovens reduce caramelizing time by maintaining ideal moisture and heat conditions, unlike regular ovens that can take longer.

How Each Oven Type Impacts Caramelization Results

Regular ovens provide consistent dry heat, which helps achieve a uniform caramelization and crisp texture, ideal for dishes like creme brulee or roasted vegetables. Combi ovens combine dry heat with steam injection, offering precise humidity control that prevents over-drying and enhances the caramelization's color and flavor depth. The choice between these ovens directly impacts caramelization quality, with combi ovens delivering more controlled and even browning, while regular ovens create a traditional, intense caramel crust.

Temperature Control: Regular Oven vs Combi Oven

How does temperature control differ between a regular oven and a combi oven for caramelizing? A regular oven provides basic temperature settings that can cause uneven heat distribution, affecting the caramelization process. In contrast, a combi oven offers precise humidity and temperature control, ensuring consistent caramelization and optimal browning.

Moisture and Steam: The Combi Oven Advantage

Combi ovens offer precise control over moisture and steam levels, crucial for perfect caramelization without burning. Regular ovens lack the ability to maintain consistent humidity, leading to uneven caramelizing results.

- Moisture Control - Combi ovens regulate humidity to prevent sugar from crystallizing excessively during caramelization.

- Steam Injection - Controlled steam injection in combi ovens helps achieve a glossy, evenly caramelized finish.

- Temperature Precision - The ovens maintain steady temperatures that avoid overheating or drying out the product.

Combi ovens enhance caramelizing by balancing steam and heat for optimal texture and flavor development.

Caramelizing Techniques in a Conventional Oven

Caramelizing in a regular oven requires precise temperature control, typically set between 350degF and 400degF, to ensure even browning without burning the sugar. Maintaining consistent heat and using a broiler setting intermittently can enhance the caramelization process by promoting Maillard reactions on the surface.

A combi oven offers advanced steam and convection settings, allowing more precise humidity and temperature control, which can prevent drying out and improve caramel texture. However, traditional ovens remain preferred for classic caramelizing techniques due to their straightforward heat application and predictable results.

Enhanced Browning with Combi Ovens

Combi ovens provide superior caramelization by combining precise humidity control with consistent heat, resulting in enhanced browning and flavor development. Regular ovens lack this moisture regulation, often leading to uneven caramelization and less vibrant color.

- Humidity Control - Combi ovens maintain optimal moisture levels that prevent drying out and promote even caramelization.

- Consistent Heat Distribution - The advanced airflow in combi ovens ensures uniform browning across all surfaces.

- Improved Flavor and Texture - Enhanced caramelization in combi ovens intensifies sweetness and develops a crisp, desirable crust on foods.

Time Efficiency: Which Oven Caramelizes Faster?

| Oven Type | Caramelizing Time | Efficiency Note |

|---|---|---|

| Regular Oven | 15-20 minutes | Slower due to uneven heat distribution |

| Combi Oven | 8-12 minutes | Faster with precise temperature and humidity control |

Flavor Development: Comparing Oven Outputs

The regular oven provides steady, radiant heat that enhances the Maillard reaction, resulting in a deep, rich caramel flavor. Combi ovens combine dry heat and steam, which can create a more evenly caramelized surface while retaining moisture and preventing burning. Flavor development in caramelizing is often more complex with a combi oven due to its precise humidity and temperature control, producing a balanced and nuanced taste.

Best Foods to Caramelize in Each Oven Type

Regular ovens excel at caramelizing root vegetables like carrots and sweet potatoes due to their consistent dry heat, which enhances natural sugars. Combi ovens provide precise humidity control, making them ideal for caramelizing fruits such as apples and pears without drying them out.

Root vegetables benefit from the even, high temperatures of a regular oven, creating a uniform caramelized crust. Combi ovens allow chefs to adjust steam levels, preserving moisture while achieving a perfect golden-brown finish on delicate fruits. This flexibility makes combi ovens superior for caramelizing diverse foods with varying moisture content.

Related Important Terms

Precision Humidity Caramelization

Combi ovens offer superior precision in humidity control, enabling consistent caramelization by maintaining ideal moisture levels that prevent burning and ensure even browning. Regular ovens lack this advanced humidity regulation, often resulting in uneven caramelization with higher risk of dryness or scorching.

Dry-Heat Maillard Zoning

A regular oven provides consistent dry heat that promotes even Maillard reaction zones essential for caramelizing surfaces, while a combi oven offers controlled humidity and steam injection that can interfere with dry-heat Maillard zoning, potentially hindering optimal caramelization. Selecting a dry-heat focused regular oven enhances crust formation and rich caramel flavors by maximizing Maillard browning without moisture dilution.

Steam-Assisted Sugar Browning

A combi oven enhances caramelizing through precise steam-assisted sugar browning, offering controlled humidity that prevents sugar from burning while achieving even browning and a glossy finish. Regular ovens lack this steam control, often resulting in uneven caramelization and a higher risk of sugar crystallization or scorching.

Low-O₂ Caramel Layering

Combi ovens offer superior control over humidity and temperature, creating an ideal low-O2 environment for even caramel layer formation with minimal oxidation compared to regular ovens. This precise atmosphere enhances Maillard reactions and sugar caramelization, resulting in a consistent golden-brown crust and intensified flavor development.

Hybrid Oven Caramel Burst

The Hybrid Oven Caramel Burst combines the precise dry heat of a regular oven with the steam injection capabilities of a combi oven, enabling superior caramelization with enhanced moisture control and even browning. This hybrid technology accelerates the Maillard reaction while preserving texture, making it ideal for consistent, high-quality caramelized finishes in commercial kitchens.

Multi-phase Oven Caramelization

Multi-phase oven caramelization in combi ovens optimizes temperature and humidity control, enabling precise browning and enhanced flavor development compared to regular ovens. This method reduces uneven caramelization and improves product consistency by alternating dry heat with controlled steam phases.

Controlled Steam Caramel Blending

Combi ovens offer precise control over steam levels, enabling optimal caramelization through controlled steam caramel blending, which prevents burning and promotes even browning. Regular ovens lack this steam regulation, often resulting in inconsistent caramelization and uneven texture.

Convection vs. Injection Caramel Profiles

Regular ovens rely primarily on convection heat to caramelize surfaces, providing even, consistent browning ideal for traditional caramel profiles. Combi ovens utilize injection technology combined with precise steam and convection controls, allowing for customizable caramel profiles by regulating moisture levels and temperature, which enhances flavor depth and texture uniformity.

Combi Flash Caramel Crusting

Combi ovens offer superior control over humidity and temperature, enabling precise caramelization for the Combi Flash Caramel Crusting process, resulting in evenly browned, glossy crusts without burning. Regular ovens lack this moisture regulation, often causing inconsistent caramelization and less desirable texture on caramelized surfaces.

Regular oven vs combi oven for caramelizing. Infographic

cookingdiff.com

cookingdiff.com