Wet caramelizing involves adding a small amount of water to sugar, allowing it to dissolve evenly before heating, which helps achieve a smoother, more controlled caramel. Dry caramelizing relies on heating sugar directly, creating a deeper, richer flavor but requires careful attention to prevent burning. Choosing between the two techniques depends on the desired flavor intensity and the level of control needed during cooking.

Table of Comparison

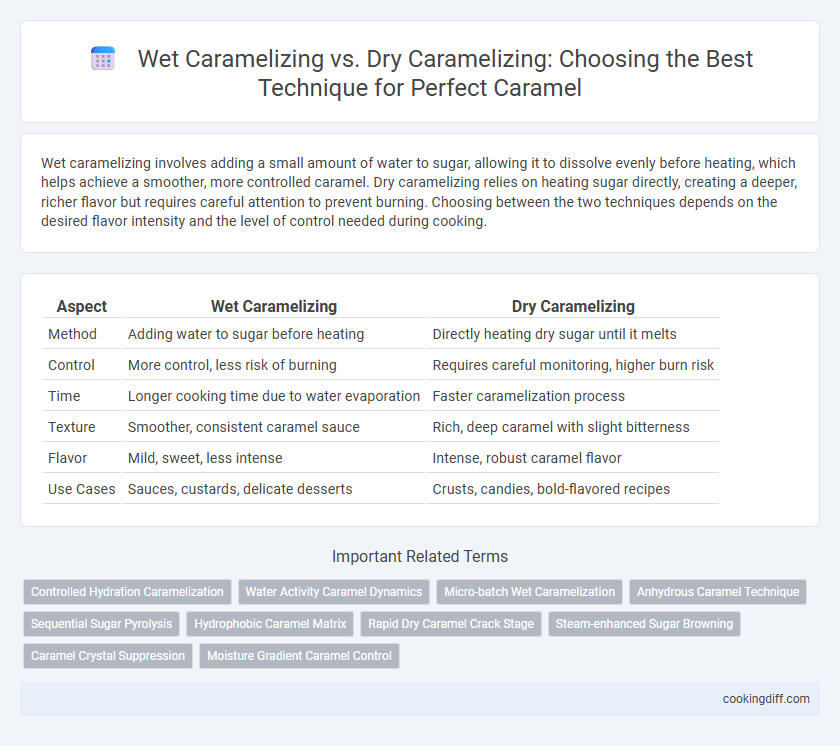

| Aspect | Wet Caramelizing | Dry Caramelizing |

|---|---|---|

| Method | Adding water to sugar before heating | Directly heating dry sugar until it melts |

| Control | More control, less risk of burning | Requires careful monitoring, higher burn risk |

| Time | Longer cooking time due to water evaporation | Faster caramelization process |

| Texture | Smoother, consistent caramel sauce | Rich, deep caramel with slight bitterness |

| Flavor | Mild, sweet, less intense | Intense, robust caramel flavor |

| Use Cases | Sauces, custards, delicate desserts | Crusts, candies, bold-flavored recipes |

Introduction to Caramelizing Techniques

Wet caramelizing involves adding water to sugar before heating, allowing for controlled melting and reducing the risk of burning. Dry caramelizing requires heating sugar directly in a pan, which produces a more intense flavor but demands careful attention to avoid charring.

Choosing between wet and dry caramelizing depends on the desired flavor profile and texture needed for the dish. Wet caramelizing offers smoother, more consistent results, while dry caramelizing provides deeper, richer caramel notes ideal for desserts requiring bold flavors.

What is Wet Caramelizing?

Wet caramelizing involves melting sugar with the addition of water, which helps dissolve the sugar evenly and prevents premature burning. This technique offers greater control over the caramelization process, resulting in a smooth, amber-colored syrup ideal for sauces and desserts. It is preferred in recipes requiring precise caramel texture and flavor development.

Understanding Dry Caramelizing

What distinguishes dry caramelizing from wet caramelizing in cooking techniques? Dry caramelizing involves heating sugar directly in a pan without adding water, allowing it to melt and brown evenly. This method yields a more intense flavor and a richer amber color compared to wet caramelizing, where water is used to dissolve sugar before heating.

Key Differences: Wet vs Dry Caramelizing

Wet caramelizing involves adding water to sugar before heating, allowing the sugar to dissolve evenly and minimize burning, making it ideal for beginners. Dry caramelizing skips water, requiring precise temperature control to melt sugar directly, resulting in deeper flavor and a richer color.

Wet caramelizing offers better temperature control and a smoother texture, while dry caramelizing provides faster cooking and a more intense caramelized taste. Choosing between techniques depends on desired flavor depth, cooking time, and skill level in temperature management.

Flavor Profiles: Choosing the Right Technique

Wet caramelizing involves adding water to sugar, resulting in a smoother, milder flavor ideal for delicate dishes, while dry caramelizing intensifies flavor with a richer, more robust caramel taste perfect for bold recipes. The choice influences the depth and complexity of the final dish's flavor profile.

- Wet caramelizing enhances subtle sweetness - Water prevents rapid burning, allowing gradual sugar dissolution and soft caramel tones.

- Dry caramelizing develops deeper, toasted notes - Direct heat caramelizes sugar faster, creating intense, nutty flavors.

- Technique impacts texture and color - Wet methods yield lighter, syrupy caramel; dry methods produce darker, crispier results.

Selecting the right caramelizing technique balances desired flavor intensity and texture for optimal culinary outcomes.

Step-by-Step Guide: Wet Caramelization

Wet caramelizing begins by dissolving sugar in water over medium heat, allowing the mixture to simmer until it reaches a golden amber color. This technique provides greater control over the caramelization process, reducing the risk of burning compared to dry caramelizing. Stirring gently and monitoring temperature closely ensures a smooth, even caramel ideal for sauces and desserts.

Step-by-Step Guide: Dry Caramelization

| Step | Action | Details |

| 1 | Heat Sugar | Place granulated sugar directly in a heavy-bottomed skillet over medium heat, avoiding stirring initially to prevent premature crystallization. |

| 2 | Monitor Melting | Watch the sugar melt and begin to turn amber; gently swirl the pan to promote even melting without introducing moisture. |

| 3 | Caramel Color Development | Continue heating until sugar reaches a deep amber hue, typically between 320degF and 350degF, for optimal caramel flavor and texture. |

| 4 | Remove from Heat | Once desired color is achieved, immediately remove the pan from heat to prevent burning and use caramel as needed. |

Equipment and Safety Tips

Wet caramelizing requires a heavy-bottomed pan to evenly distribute heat and prevent scorching, while dry caramelizing often uses a stainless steel or cast iron pan for better temperature control. Safety precautions include wearing heat-resistant gloves and keeping a bowl of cold water nearby to quickly cool any sugar burns.

- Use heavy-bottomed pans for wet caramelizing - These pans ensure even heat distribution, reducing the risk of burning the sugar mixture.

- Prefer stainless steel or cast iron for dry caramelizing - These materials handle high heat better, crucial for controlled caramelization.

- Implement safety measures - Always wear heat-resistant gloves and have cold water ready to treat sugar burns immediately.

Troubleshooting Common Caramelizing Problems

Wet caramelizing involves adding water to sugar, preventing immediate burning and allowing for smoother temperature control, ideal for beginners facing crystallization issues. Dry caramelizing requires direct heat on sugar, offering a richer flavor but risks burning if not closely monitored.

When troubleshooting common caramelizing problems, use wet caramelizing to dissolve sugar evenly and avoid grainy textures. Dry caramelizing demands constant attention and stirring to prevent bitterness from overcooking. Choosing the appropriate technique depends on desired flavor intensity and skill level, balancing control and richness.

Related Important Terms

Controlled Hydration Caramelization

Wet caramelizing involves adding water to sugar, enabling controlled hydration that prevents burning and allows for uniform melting, ideal for precise temperature management in professional cooking. Dry caramelizing heats sugar directly, requiring careful attention to prevent scorching, making wet caramelizing preferable for consistent, controlled caramel development.

Water Activity Caramel Dynamics

Wet caramelizing involves adding water to sugar, which controls the water activity and allows for even heat distribution, reducing the risk of burning while promoting a smooth caramel texture. Dry caramelizing, relying solely on direct heat without water, intensifies caramel dynamics through rapid sugar dehydration, resulting in deeper flavor profiles but requires precise temperature control to prevent crystallization or scorching.

Micro-batch Wet Caramelization

Micro-batch wet caramelization offers precise temperature control and reduced risk of burning by dissolving sugar in water before heating, making it ideal for small-scale confectionery projects. This technique contrasts with dry caramelizing, which involves direct heat application to sugar and demands more attention to avoid scorching, often suited for larger batches or when a deeper caramel flavor is desired.

Anhydrous Caramel Technique

Wet caramelizing involves dissolving sugar in water before heating, offering greater control and reducing the risk of burning, while dry caramelizing heats pure sugar directly, producing a more intense flavor but requiring careful temperature management. The anhydrous caramel technique, a form of dry caramelizing, enhances caramel's depth by heating sugar without moisture, ideal for recipes demanding rich, complex caramelization and a glossy finish.

Sequential Sugar Pyrolysis

Wet caramelizing involves dissolving sugar in water before heating, allowing controlled sequential sugar pyrolysis that reduces the risk of burning and promotes even caramel color development. Dry caramelizing directly heats granulated sugar, initiating rapid pyrolysis but requiring precise temperature control to prevent uneven caramelization and bitterness formation.

Hydrophobic Caramel Matrix

Wet caramelizing involves adding water to sugar before heating, promoting an even melt and creating a hydrophobic caramel matrix with smoother texture and reduced crystallization risk. Dry caramelizing heats sugar directly, enhancing flavor intensity but forming a less uniform hydrophobic matrix that requires precise temperature control to avoid burning.

Rapid Dry Caramel Crack Stage

Rapid dry caramel crack stage intensifies flavor development by quickly reaching higher temperatures, producing a deeper, more complex caramel profile compared to wet caramelizing, which introduces moisture that slows the process and yields a milder taste. This technique choice is essential for creating crisp texture and robust coloration in confections requiring precise caramel hardness.

Steam-enhanced Sugar Browning

Wet caramelizing utilizes water to dissolve sugar, creating steam that promotes even heat distribution and prevents burning, enhancing sugar browning through controlled steam release. Dry caramelizing heats sugar directly, risking uneven caramelization and scorching, whereas steam-enhanced wet caramelizing offers a more consistent, flavorful browning ideal for delicate desserts.

Caramel Crystal Suppression

Wet caramelizing involves adding water to sugar, which delays crystallization by dissolving sugar crystals and allowing a more controlled caramel formation, while dry caramelizing heats sugar directly, increasing the risk of unwanted caramel crystal formation. Choosing wet caramelizing enhances caramel crystal suppression and produces a smoother, more uniform caramel texture ideal for delicate culinary applications.

Wet Caramelizing vs Dry Caramelizing for technique choice. Infographic

cookingdiff.com

cookingdiff.com