A sugar thermometer provides precise temperature readings essential for caramelizing sugar, ensuring it reaches the exact stage needed for perfect pet treats. Infrared thermometers measure surface temperature without contact but can be less accurate for thick or opaque mixtures like caramel. For consistent caramelization results, a sugar thermometer is preferred due to its direct immersion and reliable heat monitoring.

Table of Comparison

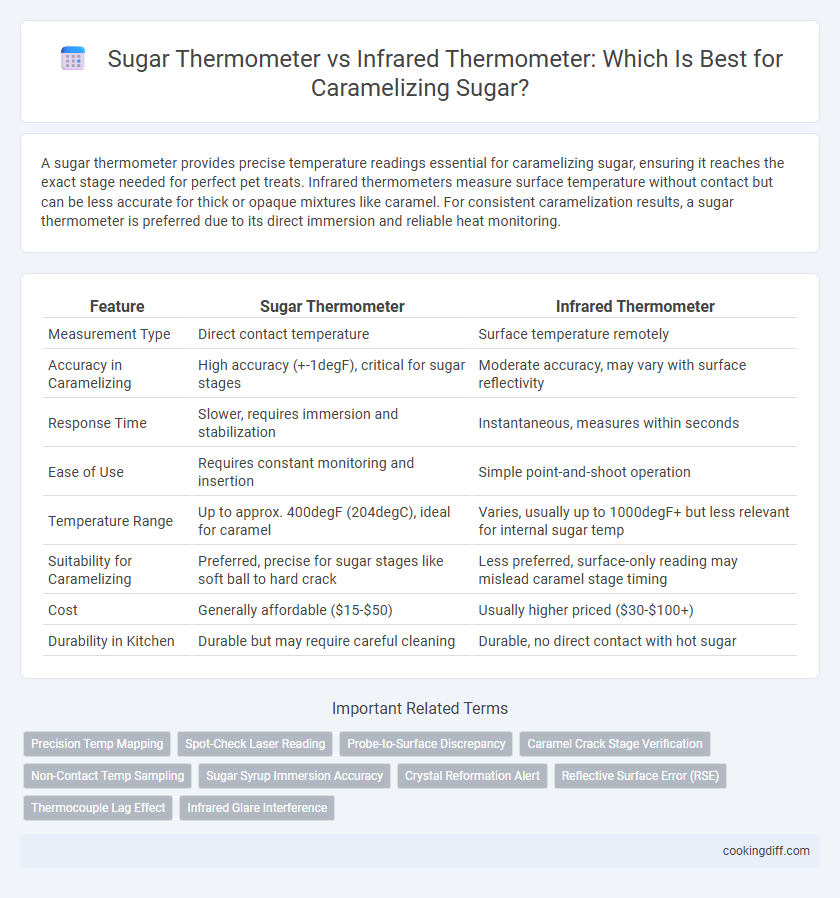

| Feature | Sugar Thermometer | Infrared Thermometer |

|---|---|---|

| Measurement Type | Direct contact temperature | Surface temperature remotely |

| Accuracy in Caramelizing | High accuracy (+-1degF), critical for sugar stages | Moderate accuracy, may vary with surface reflectivity |

| Response Time | Slower, requires immersion and stabilization | Instantaneous, measures within seconds |

| Ease of Use | Requires constant monitoring and insertion | Simple point-and-shoot operation |

| Temperature Range | Up to approx. 400degF (204degC), ideal for caramel | Varies, usually up to 1000degF+ but less relevant for internal sugar temp |

| Suitability for Caramelizing | Preferred, precise for sugar stages like soft ball to hard crack | Less preferred, surface-only reading may mislead caramel stage timing |

| Cost | Generally affordable ($15-$50) | Usually higher priced ($30-$100+) |

| Durability in Kitchen | Durable but may require careful cleaning | Durable, no direct contact with hot sugar |

Introduction to Caramelizing: Precision Matters

Caramelizing sugar requires precise temperature control to achieve the perfect golden-brown color and rich flavor without burning. A sugar thermometer, designed for direct contact with hot sugar, provides accurate readings essential for this process.

Infrared thermometers measure surface temperature without contact but can yield inconsistent results due to sugar's shiny, uneven surface. For reliable caramelizing, using a calibrated sugar thermometer ensures consistent caramel quality and prevents crystallization errors.

Understanding Sugar Thermometers in Caramelizing

Sugar thermometers provide precise temperature readings essential for achieving the exact stages of caramelization, ranging from soft ball to hard crack. Unlike infrared thermometers, they measure the internal temperature of the sugar mixture, ensuring accurate control during heating. This accuracy helps prevent burning and guarantees consistent caramel texture and color.

Infrared Thermometers: How They Work in the Kitchen

Infrared thermometers measure the surface temperature of caramel without direct contact, providing quick and accurate readings essential for perfect caramelization. They work by detecting the infrared radiation emitted by the sugar, allowing chefs to monitor temperature precisely without disturbing the cooking process.

- Non-contact measurement - Infrared thermometers read temperature from a distance by sensing thermal radiation from the sugar's surface.

- Instant temperature readings - These thermometers provide almost immediate feedback, enabling real-time adjustments during caramelization.

- Surface-specific accuracy - Infrared devices focus exclusively on surface temperature, ideal for monitoring caramel's delicate stage transitions.

Accuracy: Sugar Thermometer vs Infrared Thermometer

Accuracy is crucial when caramelizing sugar, as precise temperature control determines the perfect caramel stage. Sugar thermometers offer direct contact measurement, resulting in more reliable temperature readings than infrared thermometers that measure surface temperature only.

- Sugar Thermometer Accuracy - Provides exact liquid temperature by immersion, ensuring consistent caramelization without burning.

- Infrared Thermometer Limitations - Measures only the surface temperature, which can lead to inaccurate readings during uneven heating.

- Thermometer Suitability - Sugar thermometers are preferred for accuracy in candy making, while infrared thermometers suit quick surface checks.

Choosing a sugar thermometer improves caramelizing precision and enhances overall dessert quality.

Speed and Convenience in Temperature Monitoring

Sugar thermometers provide direct contact temperature readings essential for precise caramelization, but they require time to stabilize and careful handling. Infrared thermometers offer rapid, non-contact temperature measurements, enhancing speed and convenience during the caramelizing process.

Infrared thermometers allow instant temperature checks without contaminating the sugar mixture, making them ideal for frequent monitoring and quick adjustments. Sugar thermometers, while slower, deliver highly accurate readings necessary for achieving the perfect caramel stage. Using an infrared thermometer alongside a sugar thermometer optimizes both speed and precision in temperature control for caramelizing sugar.

Durability and Maintenance: Which Lasts Longer?

| Thermometer Type | Durability | Maintenance | Longevity |

|---|---|---|---|

| Sugar Thermometer | High durability due to stainless steel probe and heat-resistant casing | Requires regular calibration and cleaning to maintain accuracy | Typically lasts several years with proper care |

| Infrared Thermometer | Moderate durability; sensitive electronic components can be impacted by heat and moisture | Minimal maintenance, but lens cleaning and battery replacement are necessary | Shorter lifespan than sugar thermometers in high-temperature environments |

Safety Considerations: Hands-On vs Contactless Use

Using a sugar thermometer requires direct contact with the hot caramel, increasing the risk of burns and requiring careful handling. Infrared thermometers offer a contactless method, enhancing safety by allowing temperature readings from a distance without touching the sugary surface.

- Sugar thermometer demands immersion - This hands-on tool must be submerged into the caramel, exposing the user to potential splashes of hot sugar.

- Infrared thermometer enables distance measurement - It measures temperature from above without physical contact, reducing heat exposure hazards.

- Proper handling minimizes risk - Regardless of thermometer type, cautious use and protective gear improve safety when caramelizing sugar.

Versatility Beyond Caramelizing

Sugar thermometers provide precise monitoring of temperature crucial for perfect caramelizing, while infrared thermometers offer versatile, non-contact measurement applicable to various cooking tasks beyond caramelizing. Infrared thermometers excel in quickly gauging surface temperatures of pans, grills, and ovens, enhancing overall kitchen efficiency. Sugar thermometers remain indispensable for tasks requiring exact temperature control like candy making and deep frying, making both tools valuable for diverse culinary applications.

Cost Comparison: Investment for Home Cooks

Sugar thermometers typically cost between $10 and $30, making them an affordable choice for home cooks focused on precise caramelization. Infrared thermometers range from $20 to $100, representing a higher initial investment but offering versatility beyond candy making.

For home cooks primarily caramelizing sugar, a sugar thermometer provides accurate and consistent temperature readings at a lower cost. Infrared thermometers may be worth the extra expense for those seeking multifunctional tools in their kitchen arsenal.

Related Important Terms

Precision Temp Mapping

Sugar thermometers provide precise temperature readings by direct contact, enabling accurate monitoring of caramelization stages between 320degF and 350degF, essential for achieving the perfect amber color and flavor. Infrared thermometers can quickly measure surface temperature without contact but may lack the detailed precision needed for consistent temperature mapping during the complex caramelization process.

Spot-Check Laser Reading

Spot-check laser reading using an infrared thermometer provides a quick surface temperature measurement during caramelizing, but it may not accurately reflect the internal temperature of the sugar mass. In contrast, a sugar thermometer with a probe delivers precise, real-time internal temperature readings essential for perfect caramelization and preventing crystallization.

Probe-to-Surface Discrepancy

Sugar thermometers with probes provide direct contact measurement, ensuring accurate temperature readings critical for caramelizing sugar at precise stages like soft ball or hard crack. Infrared thermometers, measuring surface temperature without contact, often exhibit probe-to-surface discrepancy that can lead to inaccurate caramelization, affecting flavor and texture outcomes.

Caramel Crack Stage Verification

Sugar thermometers provide precise internal temperature readings essential for verifying the caramel crack stage, typically between 270degF and 290degF, ensuring accurate caramelization. Infrared thermometers measure surface temperature and may not reflect the true internal temperature, making them less reliable for confirming this critical caramel stage.

Non-Contact Temp Sampling

Infrared thermometers provide non-contact temperature sampling, ensuring precise measurement of sugar temperature during caramelizing without contaminating the mixture. Unlike traditional sugar thermometers that require immersion, infrared devices quickly detect surface heat, improving accuracy and preventing stirring interruptions.

Sugar Syrup Immersion Accuracy

Sugar thermometers provide precise immersion temperature readings critical for accurate caramelizing of sugar syrup, ensuring consistent caramel color and texture. Infrared thermometers measure surface temperature only, often resulting in less reliable data for controlling the internal temperature of hot sugar syrup.

Crystal Reformation Alert

A sugar thermometer provides precise, real-time measurements crucial for preventing crystal reformation during caramelizing by closely monitoring the sugar's temperature as it reaches the critical stages between 320degF and 350degF. Infrared thermometers, while quicker and non-contact, often fail to detect temperature fluctuations within the sugar mass, increasing the risk of unnoticed crystal formation that can ruin the caramel texture.

Reflective Surface Error (RSE)

Infrared thermometers often produce inaccurate readings during caramelizing due to Reflective Surface Error (RSE), as the shiny sugar surface reflects infrared radiation, causing temperature underestimation. In contrast, sugar thermometers provide precise direct contact measurements essential for achieving ideal caramelization temperatures between 320degF and 350degF.

Thermocouple Lag Effect

Sugar thermometers with thermocouples provide precise temperature readings essential for caramelizing, but they may experience lag effects due to the sensor's response time when immersed in hot sugar mixtures. Infrared thermometers measure surface temperatures instantly without contact, eliminating thermocouple lag but sometimes missing the internal temperature critical for perfect caramelization control.

Sugar thermometer vs infrared thermometer for caramelizing. Infographic

cookingdiff.com

cookingdiff.com