Cast iron skillets offer superior heat retention and even distribution, creating an ideal surface for achieving deep, rich caramelization on pet foods. Titanium-infused skillets heat quickly and resist scratching, but may not maintain consistent high temperatures as effectively as cast iron. For perfect caramelizing results, cast iron provides a more reliable and flavorful finish compared to titanium-infused alternatives.

Table of Comparison

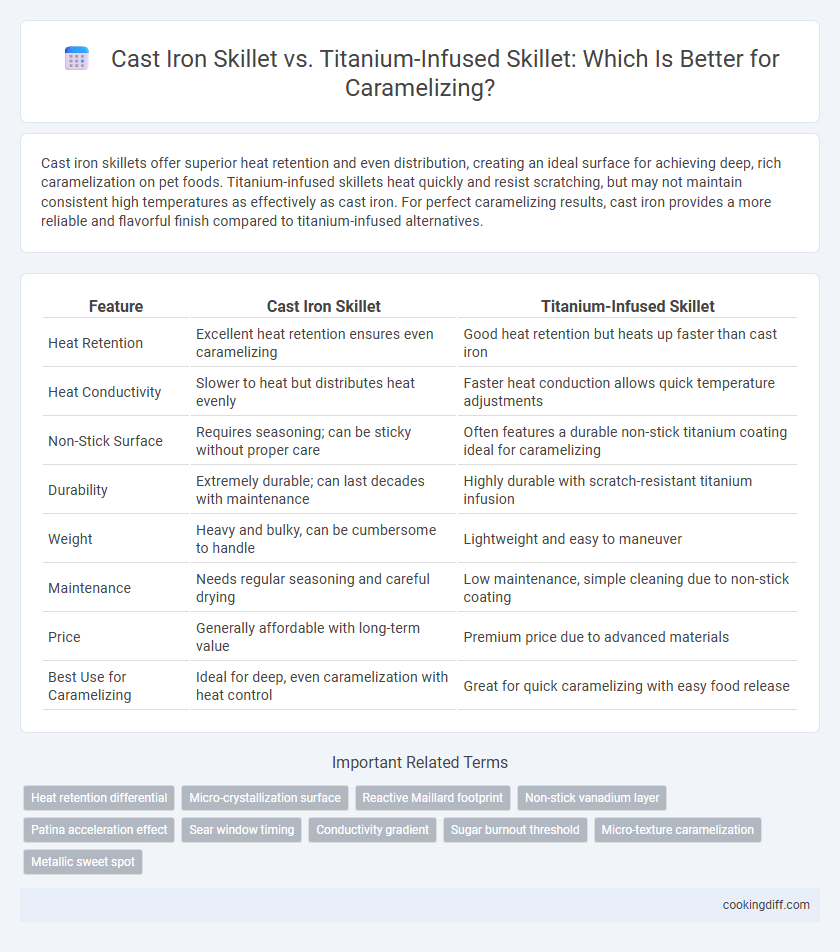

| Feature | Cast Iron Skillet | Titanium-Infused Skillet |

|---|---|---|

| Heat Retention | Excellent heat retention ensures even caramelizing | Good heat retention but heats up faster than cast iron |

| Heat Conductivity | Slower to heat but distributes heat evenly | Faster heat conduction allows quick temperature adjustments |

| Non-Stick Surface | Requires seasoning; can be sticky without proper care | Often features a durable non-stick titanium coating ideal for caramelizing |

| Durability | Extremely durable; can last decades with maintenance | Highly durable with scratch-resistant titanium infusion |

| Weight | Heavy and bulky, can be cumbersome to handle | Lightweight and easy to maneuver |

| Maintenance | Needs regular seasoning and careful drying | Low maintenance, simple cleaning due to non-stick coating |

| Price | Generally affordable with long-term value | Premium price due to advanced materials |

| Best Use for Caramelizing | Ideal for deep, even caramelization with heat control | Great for quick caramelizing with easy food release |

Introduction: The Art of Caramelizing

Caramelizing is a culinary technique that transforms sugars into rich, golden-brown flavors and aromas, enhancing the taste of various dishes. Achieving perfect caramelization requires precise temperature control and even heat distribution.

Cast iron skillets are renowned for their excellent heat retention and consistent heat, ideal for the slow, steady cooking caramelization demands. Titanium-infused skillets offer lightweight durability and rapid heating, but may lack the deep heat retention needed for evenly browning sugars. Choosing between these pans impacts the texture and flavor complexity of caramelized foods significantly.

Cast Iron Skillet Overview: Time-Tested Performance

Cast iron skillets offer unparalleled heat retention and even distribution, making them ideal for the precise temperature control required in caramelizing. Their seasoned surface enhances flavor development over time, providing a natural non-stick experience without synthetic coatings.

- Heat Retention - Cast iron maintains consistent heat longer than titanium-infused pans, essential for achieving uniform caramelization.

- Flavor Enhancement - The seasoning on cast iron skillets intensifies with use, adding depth to caramelized dishes.

- Durability - Cast iron skillets are virtually indestructible and improve with age, offering a lifetime of reliable caramelizing performance.

Titanium-Infused Skillet: Modern Innovation Explained

What makes a titanium-infused skillet ideal for caramelizing compared to a cast iron skillet? Titanium-infused skillets offer superior heat distribution and resistance to sticking, ensuring even caramelization without burning. Their lightweight design provides ease of handling while maintaining durability and enhanced non-stick properties for perfect caramelized dishes.

Heat Distribution: Cast Iron vs Titanium-Infused

Cast iron skillets offer superior heat retention and even heat distribution, making them ideal for consistent caramelizing of sugars and proteins without hot spots. Their thick construction ensures steady heat, which is crucial for achieving a deep, uniform caramelization.

Titanium-infused skillets heat up quickly but may have less even heat distribution compared to cast iron, resulting in potential uneven caramelization. While lightweight and durable, they may require more careful temperature control to avoid burning during the caramelizing process.

Retention and Responsiveness: Holding the Perfect Heat

Cast iron skillets excel in heat retention, providing steady, even temperatures essential for perfect caramelization without hot spots. Titanium-infused skillets heat up quickly and respond rapidly to temperature changes but retain heat less effectively, which can impact consistent caramelizing.

- Heat Retention - Cast iron holds high temperatures longer, maintaining consistent heat crucial for sugar caramelization.

- Responsiveness - Titanium-infused skillets adjust temperature faster, allowing precise control during cooking.

- Caramelizing Quality - Cast iron's steady heat promotes uniform browning, while titanium's quick heat loss may cause uneven caramelization.

Nonstick Qualities: Surface Differences for Caramelizing

Cast iron skillets develop a natural seasoning layer that enhances their nonstick qualities over time, making them ideal for achieving deep, even caramelization without burning. Titanium-infused skillets feature a durable, smooth surface that provides excellent nonstick performance from the start, reducing the need for additional fats during caramelizing. The porous nature of cast iron can retain heat longer, while titanium-infused surfaces offer easier cleanup and consistent nonstick properties for delicate caramelized foods.

Maintenance and Longevity: Care and Durability Compared

Cast iron skillets require regular seasoning to maintain their non-stick surface and prevent rust, while titanium-infused skillets offer a durable, corrosion-resistant coating that needs less maintenance. Both skillets provide excellent heat retention, but the titanium-infused variant typically boasts greater resistance to scratching and chipping over time.

- Seasoning Necessity - Cast iron skillets must be seasoned frequently to sustain performance and prevent rusting.

- Corrosion Resistance - Titanium-infused skillets have a naturally corrosion-resistant surface, reducing upkeep efforts.

- Durability - Titanium-infused pans resist scratches and chips better, enhancing long-term usability.

Choosing between the two depends on your preferred maintenance routine and durability requirements for caramelizing.

Flavor Development: Does the Skillet Impact Taste?

| Skillet Type | Flavor Development |

| Cast Iron Skillet | Provides superior heat retention and even distribution, promoting deep, rich caramelization and enhanced flavor complexity due to the reactive surface interacting with sugars. |

| Titanium-Infused Skillet | Offers quick heat response with non-reactive surface, which may result in less pronounced caramel flavor development but ensures consistent browning without metallic taste interference. |

Practical Use: Weight, Handling, and User Experience

Cast iron skillets are heavier and require more effort to maneuver, which can impact user comfort during prolonged caramelizing sessions. Titanium-infused skillets are lighter, offering easier handling and quicker temperature adjustments, enhancing overall cooking efficiency.

Despite its weight, cast iron provides superior heat retention and even heat distribution, essential for consistent caramelization. Titanium-infused skillets, while lighter, may lack the same heat retention but excel in responsiveness and ease of use for delicate tasks.

Related Important Terms

Heat retention differential

Cast iron skillets excel in heat retention, maintaining consistent high temperatures essential for even caramelization, while titanium-infused skillets, though lightweight, dissipate heat more quickly, potentially causing uneven browning. The superior thermal mass of cast iron ensures precise temperature control, making it the preferred choice for achieving rich, deeply caramelized flavors.

Micro-crystallization surface

A cast iron skillet excels in caramelizing due to its micro-crystallization surface, which promotes even heat retention and creates a superior Maillard reaction essential for deep caramel flavors. In contrast, a titanium-infused skillet offers durability and non-stick benefits but lacks the same micro-crystallized texture, resulting in less effective caramelization compared to cast iron.

Reactive Maillard footprint

Cast iron skillets, known for their superior heat retention and even distribution, create a deeper Maillard reaction, enhancing caramelization with a richer, more complex flavor profile. Titanium-infused skillets, while offering durability and non-reactivity, produce a milder Maillard footprint, resulting in less intense caramelization compared to cast iron surfaces.

Non-stick vanadium layer

A cast iron skillet provides excellent heat retention crucial for even caramelization, while a titanium-infused skillet featuring a non-stick vanadium layer offers superior surface durability and faster cleanup. The vanadium-infused non-stick coating enhances resistance to sticking without compromising the skillet's ability to achieve the high, consistent temperatures necessary for perfect caramelization.

Patina acceleration effect

Cast iron skillets accelerate the patina formation due to their porous surface, enhancing caramelization by retaining heat evenly and developing a natural non-stick layer that improves flavor over time. Titanium-infused skillets, while durable and quick to heat, lack this patina-accelerating property, resulting in less efficient caramelization and a less developed seasoning layer.

Sear window timing

Cast iron skillets offer a wider and more stable sear window due to their superior heat retention and even heat distribution, allowing precise caramelization without quick temperature drops. Titanium-infused skillets heat up faster but have a narrower sear window, making temperature control critical to prevent burning or uneven caramelization.

Conductivity gradient

Cast iron skillets exhibit a high thermal mass and an even conductivity gradient, promoting consistent heat retention essential for uniform caramelization. In contrast, titanium-infused skillets offer rapid heat distribution but may have a less stable conductivity gradient, potentially causing uneven caramelization.

Sugar burnout threshold

Cast iron skillets have a higher heat retention and even heat distribution, making them ideal for reaching and maintaining the sugar burnout threshold of around 320degF (160degC) required for perfect caramelization without burning. Titanium-infused skillets heat up faster but often have a lower burnout threshold and less even heat, increasing the risk of uneven caramelization and burnt sugar.

Micro-texture caramelization

Cast iron skillets provide superior heat retention and even distribution essential for optimal micro-texture caramelization, allowing sugar molecules to break down uniformly and develop complex flavor profiles. Titanium-infused skillets, while lightweight and durable, often offer less consistent heat, which can result in uneven caramelization and less refined micro-texture development.

Cast iron skillet vs titanium-infused skillet for caramelizing. Infographic

cookingdiff.com

cookingdiff.com