A copper saucepan offers superior heat conductivity and precise temperature control, making it ideal for caramelizing sugar evenly without burning. In contrast, a carbon steel skillet heats more gradually and retains heat longer, which can result in uneven caramelization and potential hot spots. For consistent, delicate caramelization, a copper saucepan is generally preferred over a carbon steel skillet.

Table of Comparison

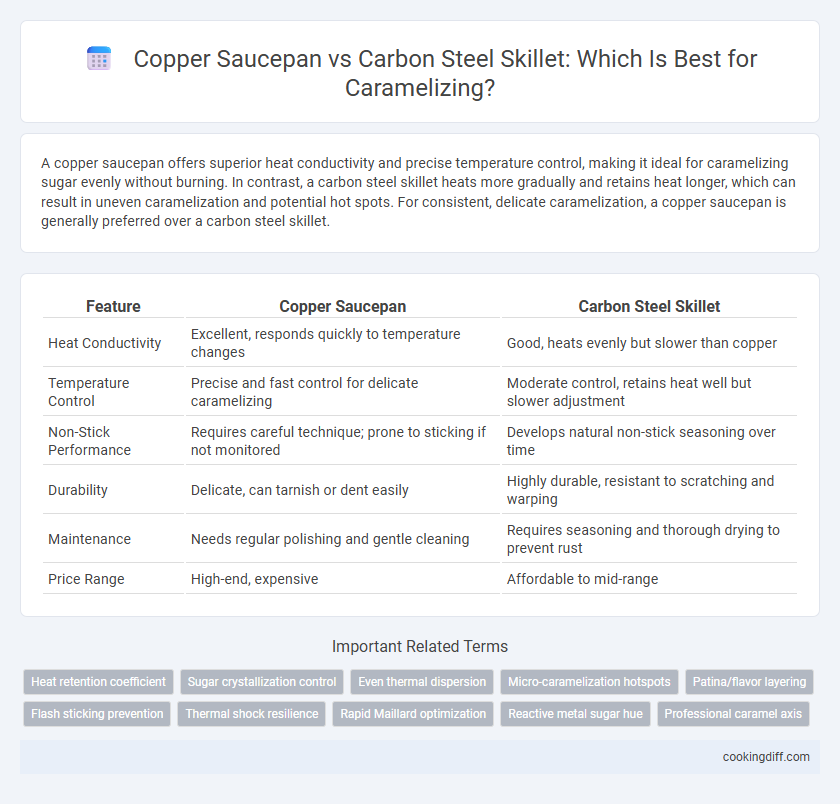

| Feature | Copper Saucepan | Carbon Steel Skillet |

|---|---|---|

| Heat Conductivity | Excellent, responds quickly to temperature changes | Good, heats evenly but slower than copper |

| Temperature Control | Precise and fast control for delicate caramelizing | Moderate control, retains heat well but slower adjustment |

| Non-Stick Performance | Requires careful technique; prone to sticking if not monitored | Develops natural non-stick seasoning over time |

| Durability | Delicate, can tarnish or dent easily | Highly durable, resistant to scratching and warping |

| Maintenance | Needs regular polishing and gentle cleaning | Requires seasoning and thorough drying to prevent rust |

| Price Range | High-end, expensive | Affordable to mid-range |

Introduction: The Art of Caramelizing

| Caramelizing requires precise temperature control and even heat distribution to achieve the perfect golden-brown color and rich flavor. Copper saucepans excel due to their superior thermal conductivity, allowing rapid and consistent heat adjustments essential for sugar caramelization. Carbon steel skillets offer durability and heat retention but may develop hot spots, making them less ideal for the delicate process of caramelizing sugar. |

Why Pan Choice Matters for Caramelization

The choice between a copper saucepan and a carbon steel skillet significantly impacts caramelization due to differences in heat conductivity and temperature control. Copper pans offer rapid, even heat distribution, while carbon steel skillets provide excellent heat retention and develop a natural non-stick surface over time.

- Copper saucepan offers superior heat responsiveness - This allows precise temperature adjustments crucial for preventing burnt caramel.

- Carbon steel skillet retains heat efficiently - It ensures consistent caramelization by maintaining steady heat once hot.

- Copper's smooth surface aids easy stirring - This helps achieve uniform caramel without sticking or burning.

Choosing the right pan enhances caramelization quality and cooking control.

Copper Saucepan: Heat Conductivity and Control

Copper saucepans offer superior heat conductivity, allowing for precise temperature control essential in the delicate process of caramelizing sugar. This responsiveness helps prevent burning and promotes even caramelization.

- High Thermal Conductivity - Copper transfers heat quickly and evenly, reducing hot spots during caramelization.

- Precise Temperature Control - The rapid response to heat changes enables fine adjustments, crucial for achieving perfect caramel color and texture.

- Consistent Cooking Surface - Copper pans maintain stable heat, ensuring sugar caramelizes uniformly without sudden temperature fluctuations.

Carbon Steel Skillet: Versatility and Performance

Carbon steel skillets offer exceptional heat conductivity and retention, making them ideal for achieving consistent caramelization. Their naturally non-stick surface improves with seasoning, allowing sugars to caramelize evenly without sticking or burning.

Unlike copper saucepans, carbon steel skillets combine durability and versatility, suitable for high-heat cooking and deglazing processes. This performance adaptability enhances flavor development in caramelized dishes, providing precise temperature control and optimal browning.

Temperature Distribution: Comparing Both Materials

Copper saucepans offer superior temperature distribution due to copper's excellent thermal conductivity, enabling precise control over caramelization heat. Carbon steel skillets heat quickly but can have uneven temperature distribution, leading to hot spots that may cause burning.

Copper's even heat distribution ensures consistent caramelization without frequent temperature adjustments, making it ideal for delicate sugar work. In contrast, carbon steel requires more attentive heat management to prevent localized overheating. This difference impacts the final texture and color uniformity in caramelized dishes.

Responsiveness During Caramelizing

Copper saucepans offer superior responsiveness during caramelizing due to their excellent thermal conductivity, enabling precise temperature control and even heat distribution. Carbon steel skillets heat up quickly but retain heat longer, which can make fine temperature adjustments more challenging when caramelizing sugar. This responsiveness difference impacts the ability to prevent burning and achieve a smooth, golden caramel.

Ease of Monitoring Sugar Color and Aroma

Copper saucepans offer superior heat conductivity, providing precise control over temperature changes essential for monitoring sugar color and aroma during caramelizing. Carbon steel skillets, while durable, heat less evenly, which can lead to uneven caramelization and make it harder to detect subtle changes in sugar's appearance and scent. The smooth surface of copper enhances visibility of the caramel's color gradients, aiding in achieving the perfect caramelization stage.

Cleaning and Maintenance Considerations

Copper saucepans require regular polishing to maintain their lustrous appearance and prevent tarnishing, making cleaning more labor-intensive. They also react with acidic ingredients, so a tin or stainless steel lining is essential to avoid flavor alteration and corrosion during caramelizing.

Carbon steel skillets develop a natural non-stick patina with seasoning but need careful drying and oiling after each use to prevent rust. Their simpler maintenance and durability make them a practical choice for frequent caramelizing tasks despite occasional re-seasoning requirements.

Best Uses: Which Pan Wins for Caramelizing?

Which pan is best for caramelizing: a copper saucepan or a carbon steel skillet? Copper saucepans provide precise temperature control, essential for preventing sugar from burning during caramelization. Carbon steel skillets offer even heat distribution and excellent heat retention, making them ideal for achieving a deep, consistent caramel color.

Related Important Terms

Heat retention coefficient

A copper saucepan offers superior heat retention coefficient compared to a carbon steel skillet, enabling more consistent and precise temperature control during caramelizing. This efficient heat retention prevents sudden temperature drops, ensuring evenly caramelized sugar and a smoother texture.

Sugar crystallization control

Copper saucepans provide superior heat conductivity and precise temperature control, essential for preventing sugar crystallization during caramelizing. Carbon steel skillets retain heat unevenly, increasing the risk of hot spots that can cause premature sugar crystallization and uneven caramel color development.

Even thermal dispersion

Copper saucepans provide superior even thermal dispersion, allowing precise temperature control essential for perfect caramelizing without hot spots. Carbon steel skillets heat quickly but distribute heat less uniformly, increasing the risk of uneven caramelization.

Micro-caramelization hotspots

Copper saucepans provide superior heat conductivity and precise temperature control, which minimizes micro-caramelization hotspots for an even caramelization process. Carbon steel skillets tend to develop uneven heat zones that can create localized micro-caramelization, potentially leading to inconsistent browning and flavor development.

Patina/flavor layering

Copper saucepans offer precise temperature control essential for even caramelization, while developing less patina compared to carbon steel skillets. Carbon steel skillets build a rich patina over time that enhances flavor layering and creates a natural non-stick surface ideal for deep caramelized notes.

Flash sticking prevention

Copper saucepans offer superior heat conductivity and precise temperature control, reducing hotspots that cause sugar to flash stick during caramelizing. Carbon steel skillets, while durable, have less uniform heat distribution, increasing the risk of sugar crystallization and sticking if not carefully managed.

Thermal shock resilience

Copper saucepans excel in rapid, even heat distribution but are less resilient to thermal shock, risking warping when exposed to sudden temperature changes. Carbon steel skillets offer superior thermal shock resistance, maintaining structural integrity with temperature fluctuations, making them more durable for caramelizing processes requiring fast heating and cooling.

Rapid Maillard optimization

Copper saucepans offer superior thermal conductivity, enabling rapid and precise temperature control essential for optimizing the Maillard reaction during caramelizing. Carbon steel skillets, while durable and capable of high heat retention, heat less evenly than copper, potentially leading to uneven browning and slower Maillard development.

Reactive metal sugar hue

Copper saucepans provide precise heat control essential for uniform caramelization, while their reactive nature can slightly alter sugar hue due to metal interaction. Carbon steel skillets offer quick heat response with minimal reactivity, preserving the natural amber color of caramelized sugar more consistently.

Copper saucepan vs carbon steel skillet for caramelizing. Infographic

cookingdiff.com

cookingdiff.com