A chef's torch offers precise control and immediate caramelization, creating a perfectly crisp and golden crust on desserts like creme brulee. Infrared caramelizers provide consistent, even heat over a larger surface, ideal for caramelizing multiple items simultaneously without the risk of burning. Choosing between the two depends on the efficiency needed and the level of detail required for each caramelizing task.

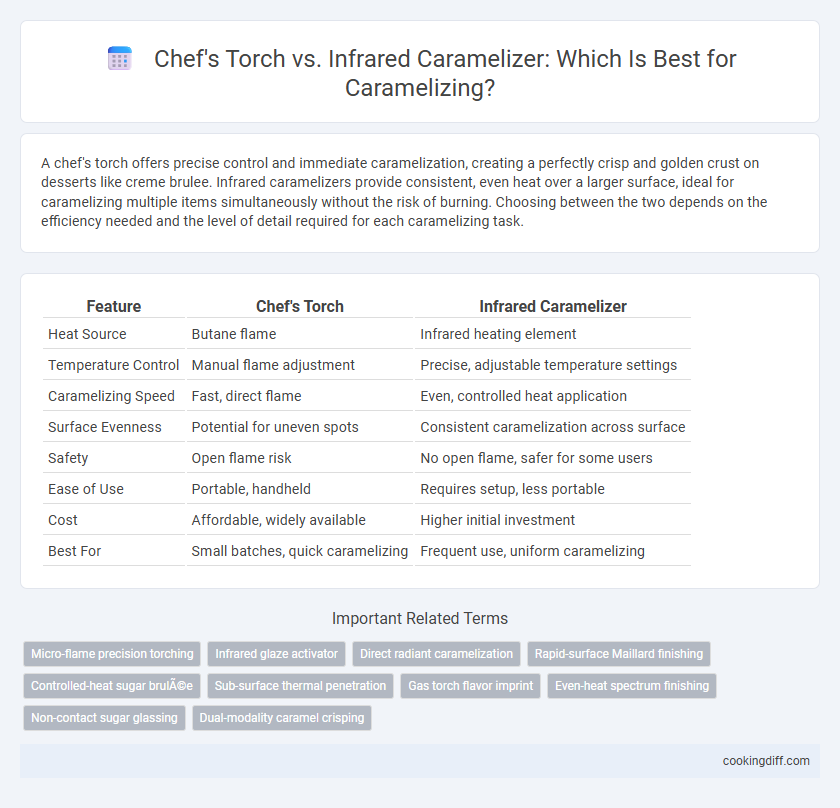

Table of Comparison

| Feature | Chef's Torch | Infrared Caramelizer |

|---|---|---|

| Heat Source | Butane flame | Infrared heating element |

| Temperature Control | Manual flame adjustment | Precise, adjustable temperature settings |

| Caramelizing Speed | Fast, direct flame | Even, controlled heat application |

| Surface Evenness | Potential for uneven spots | Consistent caramelization across surface |

| Safety | Open flame risk | No open flame, safer for some users |

| Ease of Use | Portable, handheld | Requires setup, less portable |

| Cost | Affordable, widely available | Higher initial investment |

| Best For | Small batches, quick caramelizing | Frequent use, uniform caramelizing |

Introduction to Caramelizing Techniques

Chef's torch delivers precise control and intense direct flame, ideal for quickly caramelizing sugar atop desserts like creme brulee. Infrared caramelizers use radiant heat to evenly caramelize larger surfaces without open flames, making them suitable for professional kitchens.

Chef's torch provides targeted caramelizing with adjustable flame intensity, perfect for delicate finishing touches on individual dishes. Infrared caramelizers ensure consistent caramelization across broader areas, minimizing the risk of burning and enabling faster preparation for multiple servings. Choosing between these tools depends on the scale and precision required in culinary applications.

What Is a Chef’s Torch?

What is a Chef's torch and how does it differ from an infrared caramelizer? A Chef's torch is a handheld tool that emits a controlled flame ideal for caramelizing sugar on desserts like creme brulee, providing precision and direct heat. Unlike infrared caramelizers that use radiant heat, the torch allows chefs to target specific areas quickly for an even caramelized finish.

Understanding the Infrared Caramelizer

The infrared caramelizer uses radiant heat to evenly caramelize sugar surfaces without direct flame contact, providing consistent results. Unlike a chef's torch, it offers precise temperature control and reduced risk of burning delicate desserts.

- Efficient Heat Distribution - Infrared caramelizers emit heat that penetrates sugar layers uniformly for smooth caramelization.

- Temperature Precision - Allows setting exact heat levels to avoid overheating or undercooking sugar toppings.

- Safer Operation - Eliminates open flames, reducing fire hazards in professional and home kitchens.

Infrared caramelizers combine safety and consistency, making them a modern alternative to traditional chef's torches.

Heat Distribution: Torch vs. Infrared

Chef's torch provides direct, intense heat that allows precise control over caramelization, creating a crisp, evenly browned crust on desserts like creme brulee. Infrared caramelizers distribute heat more uniformly across the surface, reducing hot spots and producing consistent caramelization without burning. While torches offer quick, localized flame application, infrared devices excel in steady, low-temperature heat suitable for larger or more delicate caramelizing tasks.

Precision and Control in Caramelization

Chef's torches offer precise flame control, allowing chefs to target specific areas for even caramelization without overheating surrounding ingredients. This tool provides adjustable intensity and immediate flame application, ensuring consistent browning and caramel development.

Infrared caramelizers use focused heat waves to achieve uniform caramelization across larger surfaces, reducing the risk of uneven burning. Their automated temperature regulation delivers steady control but can lack the fine-tuned precision achievable with a manual torch.

Speed and Efficiency Comparison

| Method | Speed | Efficiency |

|---|---|---|

| Chef's Torch | Provides precise, quick caramelization with direct flame targeting; ideal for small batches or delicate desserts like creme brulee. | Consumes less energy and allows controlled caramelization, minimizing waste and ensuring even browning. |

| Infrared Caramelizer | Heats larger surface areas rapidly; suitable for commercial-scale caramelizing and continuous production lines. | Uses infrared radiation to evenly caramelize with minimal heat loss, increasing throughput and reducing cooking time. |

Flavor and Texture Differences

Chef's torches provide intense, direct heat that creates a deeply caramelized, slightly smoky flavor and a crisp, unevenly blistered texture favored in traditional creme brulee. Infrared caramelizers use a broader, radiant heat source resulting in a more uniform caramelization with a subtler, sweeter flavor profile and a smoother, glass-like crust.

The torch's rapid caramelization can quickly develop complex Maillard reactions enhancing depth, while infrared heat gently melts sugar crystals, maintaining a delicate crunch without burning. Choosing between these tools depends on desired flavor intensity and texture, with torches preferred for dramatic contrast and infrared for consistent caramel surfaces.

Safety Considerations for Home Cooks

When caramelizing at home, safety is paramount, especially when choosing between a chef's torch and an infrared caramelizer. While both tools effectively caramelize sugar, understanding their safety aspects can prevent accidents and ensure a smooth cooking experience.

- Open Flame Risks - Chef's torches use an open flame, increasing the risk of burns and fire hazards if not handled carefully.

- No Direct Flame - Infrared caramelizers operate without an open flame, reducing fire risk and making them safer for beginners.

- Ventilation Needs - Both devices require good kitchen ventilation to avoid buildup of gases or smoke during caramelizing.

Maintenance and Durability

Chef's torches require regular refilling of fuel and careful cleaning to maintain optimal flame output, which can affect their longevity. Infrared caramelizers have fewer moving parts and generally need less frequent maintenance, contributing to enhanced durability over time.

- Chef's torch fuel refills - Must be replenished often to ensure consistent caramelizing performance.

- Infrared caramelizer components - Designed with minimal mechanical parts, reducing wear and tear.

- Cleaning requirements - Chef's torches demand thorough cleaning to avoid clogging, whereas infrared caramelizers are easier to maintain due to simpler design.

Related Important Terms

Micro-flame precision torching

Micro-flame precision torching with a chef's torch delivers controlled, localized heat essential for evenly caramelizing sugar without burning, enhancing flavor and texture. Compared to infrared caramelizers, the torch offers superior maneuverability and immediate flame adjustment, crucial for delicate desserts like creme brulee.

Infrared glaze activator

The infrared glaze activator provides consistent, even heat that effectively melts sugar crystals to create a flawless caramelized crust without burning. Unlike the chef's torch, it offers precision temperature control and uniform glazing, enhancing both texture and flavor in delicate desserts.

Direct radiant caramelization

Chef's torches deliver intense, direct radiant heat that quickly caramelizes sugars with precision and control, producing a rich, evenly browned crust ideal for delicate desserts like creme brulee. Infrared caramelizers use focused radiant energy to uniformly caramelize surfaces without flames, offering consistent color and texture while minimizing the risk of burning or uneven spots.

Rapid-surface Maillard finishing

A chef's torch delivers precise, high-temperature flames ideal for rapid surface Maillard reactions, creating a crisp, deeply caramelized crust on desserts like creme brulee. Infrared caramelizers provide even heat distribution with controlled temperature settings, ensuring consistent browning but often lack the intense, focused heat required for instant Maillard finishing.

Controlled-heat sugar brulée

Chef's torches provide precise, direct flames that allow for meticulous control over the caramelization of sugar brulee, achieving an even, golden crust without overheating. Infrared caramelizers use radiant heat to uniformly caramelize the surface, reducing the risk of burning but offering slightly less targeted heat control compared to a chef's torch.

Sub-surface thermal penetration

Chef's torch delivers intense, localized heat with shallow sub-surface thermal penetration, ideal for rapidly caramelizing sugar on delicate desserts without overheating underlying layers. In contrast, infrared caramelizers provide deeper, more uniform sub-surface thermal penetration, enabling even caramelization with reduced risk of burning the surface or leaving cold spots beneath.

Gas torch flavor imprint

Chef's gas torch imparts a distinct smoky flavor and precise control over caramelization, enhancing desserts with a rich, slightly charred aroma that infrared caramelizers lack. Infrared caramelizers provide even heat distribution but do not replicate the nuanced flavor profile achieved through direct flame contact by a gas torch.

Even-heat spectrum finishing

Chef's torches provide precise, localized caramelizing with high-temperature flames ideal for small, controlled areas, while infrared caramelizers deliver an even-heat spectrum that ensures uniform browning across larger surfaces. Infrared technology penetrates food's surface evenly, minimizing hot spots and enhancing texture consistency in desserts like creme brulee.

Non-contact sugar glassing

Chef's torches offer precise, high-temperature flames ideal for caramelizing sugar with direct heat, creating a smooth, glass-like finish, but they require careful handling to avoid uneven burning. Infrared caramelizers provide non-contact sugar glassing by emitting consistent radiant heat, ensuring uniform caramelization and eliminating the risk of charring or burning sugar surfaces.

Chef’s torch vs infrared caramelizer for caramelizing. Infographic

cookingdiff.com

cookingdiff.com