Copper pans offer exceptional heat conductivity, providing precise temperature control essential for even caramelization without burning sugar. Carbon steel woks excel in rapid heat distribution and high heat retention, allowing quick caramelization and easy stirring in a larger cooking area. Choosing between them depends on whether you prioritize temperature precision or versatility and capacity during the caramelizing process.

Table of Comparison

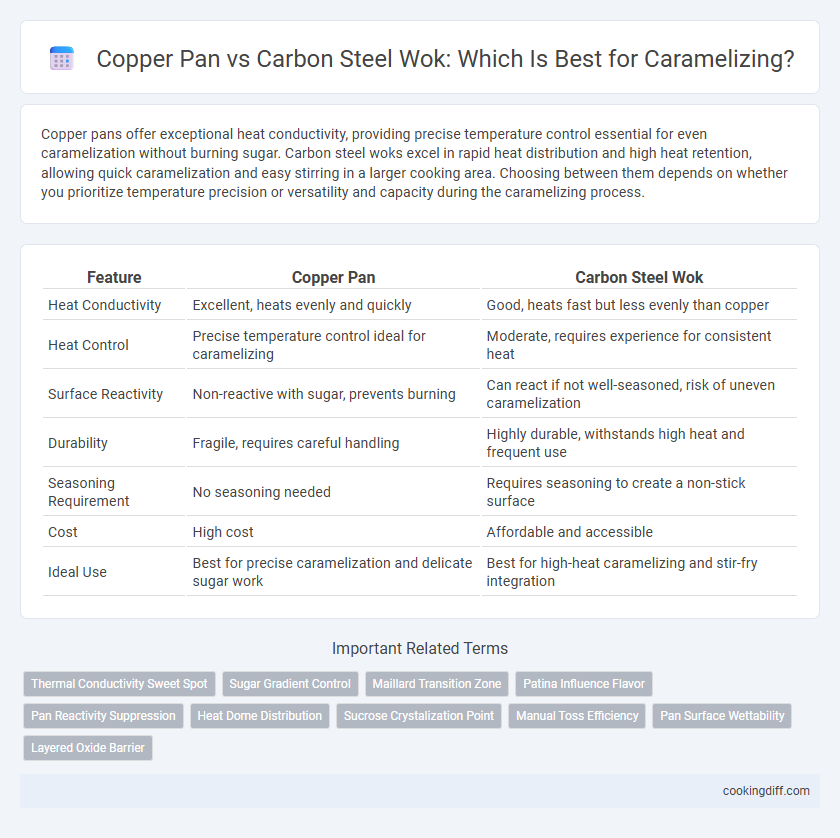

| Feature | Copper Pan | Carbon Steel Wok |

|---|---|---|

| Heat Conductivity | Excellent, heats evenly and quickly | Good, heats fast but less evenly than copper |

| Heat Control | Precise temperature control ideal for caramelizing | Moderate, requires experience for consistent heat |

| Surface Reactivity | Non-reactive with sugar, prevents burning | Can react if not well-seasoned, risk of uneven caramelization |

| Durability | Fragile, requires careful handling | Highly durable, withstands high heat and frequent use |

| Seasoning Requirement | No seasoning needed | Requires seasoning to create a non-stick surface |

| Cost | High cost | Affordable and accessible |

| Ideal Use | Best for precise caramelization and delicate sugar work | Best for high-heat caramelizing and stir-fry integration |

Introduction to Caramelizing: Why Pan Choice Matters

Caramelizing requires precise temperature control to achieve the perfect balance of sweetness and depth of flavor. Choosing the right pan significantly affects heat distribution and the caramelization process.

- Copper Pan Superior Heat Conductivity - Copper pans heat quickly and evenly, allowing for precise temperature adjustments essential for uniform caramelization.

- Carbon Steel Wok High Heat Retention - Carbon steel woks retain heat well and develop a natural non-stick surface, making them ideal for high-heat, fast caramelizing techniques.

- Reactivity and Flavor Impact - Copper is reactive with acidic ingredients, potentially altering flavor, while carbon steel is less reactive, preserving the intended caramel notes.

Understanding these differences helps cooks select the best pan to enhance caramelizing outcomes based on their cooking style and recipe requirements.

Copper Pan: Features and Benefits for Caramelizing

Copper pans offer exceptional heat conductivity, allowing precise temperature control essential for caramelizing sugar evenly without burning. Their rapid response to temperature changes minimizes the risk of caramelizing inconsistently, which is crucial for achieving the perfect amber color and flavor.

The even heat distribution of copper pans ensures uniform caramelization across the entire surface, preventing hot spots that can cause bitterness. This makes copper cookware a preferred choice for chefs aiming for consistent, high-quality caramelized dishes.

Carbon Steel Wok: Properties and Performance in Caramelizing

Carbon steel woks offer excellent heat conductivity and rapid temperature response, essential for precise caramelizing. Their lightweight construction allows for effortless tossing and even caramel distribution, enhancing flavor development.

The wok's naturally non-stick surface, which improves with seasoning, prevents sugar from sticking and burning during caramelization. Compared to copper pans, carbon steel woks provide superior durability and high-heat tolerance, making them ideal for intense caramelizing tasks.

Heat Conductivity: Copper vs. Carbon Steel

Which material offers better heat conductivity for caramelizing, copper or carbon steel? Copper pans provide superior heat conductivity, allowing for precise temperature control and even caramelization. Carbon steel woks heat up quickly but distribute heat less evenly compared to copper, which can affect the consistency of the caramelization process.

Evenness of Cooking: Comparing Surface Temperatures

Copper pans offer superior heat conductivity, providing more even surface temperatures ideal for precise caramelizing. Carbon steel woks tend to have hotspots due to their lower thermal conductivity, which can cause uneven caramelization. For consistent browning and controlled temperature, copper pans are generally preferred in professional kitchens.

Reaction Time and Control Over Caramelization

Copper pans provide superior thermal conductivity, allowing rapid reaction time and precise control over caramelization. The even heat distribution prevents hot spots, reducing the risk of burning sugar during the caramelization process.

Carbon steel woks heat up quickly but have less consistent heat retention compared to copper pans, leading to uneven caramelization. Their thicker material requires more careful temperature management to avoid scorching. However, with practice, carbon steel woks can offer sufficient control for achieving a rich, evenly caramelized result.

Ease of Cleaning After Caramelizing Sugars

Copper pans offer superior heat conductivity, allowing for precise caramelization, but their smooth surface makes caramel residue easier to clean compared to a carbon steel wok. Carbon steel woks, while excellent for high-heat cooking, tend to develop sticky caramelized sugar residues that require thorough scrubbing and seasoning maintenance. For ease of cleaning after caramelizing sugars, copper pans are often preferred due to their non-reactive, smooth surface which prevents stubborn buildup.

Durability and Maintenance: Long-Term Use

Copper pans offer excellent heat conductivity but require regular polishing to prevent tarnish and maintain their appearance, impacting long-term maintenance. Carbon steel woks develop a natural non-stick patina with use, enhancing durability and simplifying upkeep over time.

- Copper pans demand frequent polishing - This prevents discoloration and preserves their thermal efficiency during caramelizing.

- Carbon steel woks become more non-stick - Regular seasoning builds a protective layer that improves caramelizing performance and durability.

- Copper is softer and prone to dents - Careful handling is necessary to sustain the pan's longevity in long-term use.

Flavor Development: Impact of Pan Materials

| Pan Material | Flavor Development Impact |

| Copper Pan | Provides precise heat control, enabling gradual caramelization that enhances sweet and nutty flavor compounds without burning. |

| Carbon Steel Wok | Heats quickly with high temperatures promoting Maillard reactions that create deeper, more complex caramelized flavors with slight smokiness. |

Related Important Terms

Thermal Conductivity Sweet Spot

Copper pans offer superior thermal conductivity, heating up quickly and responding instantly to temperature changes, making them ideal for achieving the perfect caramelization without burning. Carbon steel woks provide a balanced thermal conductivity that distributes heat evenly and retains warmth longer, creating a sweet spot for controlled caramelizing with better heat management.

Sugar Gradient Control

Copper pans provide superior sugar gradient control when caramelizing due to their exceptional thermal conductivity, enabling precise and even heat distribution that prevents hotspots and burning. Carbon steel woks heat quickly but distribute heat less evenly, which can lead to inconsistent caramelization and difficulty maintaining gradual sugar color changes.

Maillard Transition Zone

Copper pans offer precise temperature control essential for maintaining the Maillard Transition Zone between 140degC and 165degC during caramelizing, ensuring even browning without burning. Carbon steel woks, prized for rapid heat conduction, can quickly surpass this temperature range, increasing the risk of scorching and uneven caramel development.

Patina Influence Flavor

Copper pans offer superior heat conductivity for precise caramelizing, but their smooth surface limits patina development, resulting in cleaner, more controlled flavor profiles. Carbon steel woks develop a rich patina over time that enhances caramel complexity and depth, lending a subtle smoky dimension to dishes.

Pan Reactivity Suppression

Copper pans offer superior heat conductivity and precise temperature control for caramelizing, minimizing the risk of burning and ensuring even browning. Carbon steel woks, while highly durable and versatile, may react more with acidic caramel mixtures, potentially altering flavor profiles and requiring careful seasoning to suppress reactivity during caramelization.

Heat Dome Distribution

Copper pans excel in caramelizing due to their superior heat dome distribution, providing even and precise temperature control that prevents hotspots and ensures consistent browning. Carbon steel woks, while quick to heat, often have uneven heat distribution in the dome area, which can cause irregular caramelization and require constant temperature management.

Sucrose Crystalization Point

Copper pans conduct heat rapidly and evenly, allowing precise control just below sucrose's crystallization point of approximately 186degC (367degF), essential for smooth caramelization without graininess. Carbon steel woks heat quickly but less uniformly, increasing the risk of localized hotspots that can surpass sucrose's crystallization temperature, leading to uneven caramel texture.

Manual Toss Efficiency

Copper pans offer superior heat conductivity, allowing for rapid and even caramelization with precise temperature control that enhances manual tossing efficiency. Carbon steel woks, while durable and quick to heat, may develop hot spots that require more skillful tossing to achieve consistent caramelization results.

Pan Surface Wettability

Copper pans offer superior surface wettability compared to carbon steel woks, allowing for even caramelization due to excellent heat conductivity and consistent temperature control. Carbon steel woks, while versatile and lightweight, have lower wettability, which can result in uneven caramelization and increased risk of hot spots during cooking.

Copper pan vs carbon steel wok for caramelizing. Infographic

cookingdiff.com

cookingdiff.com