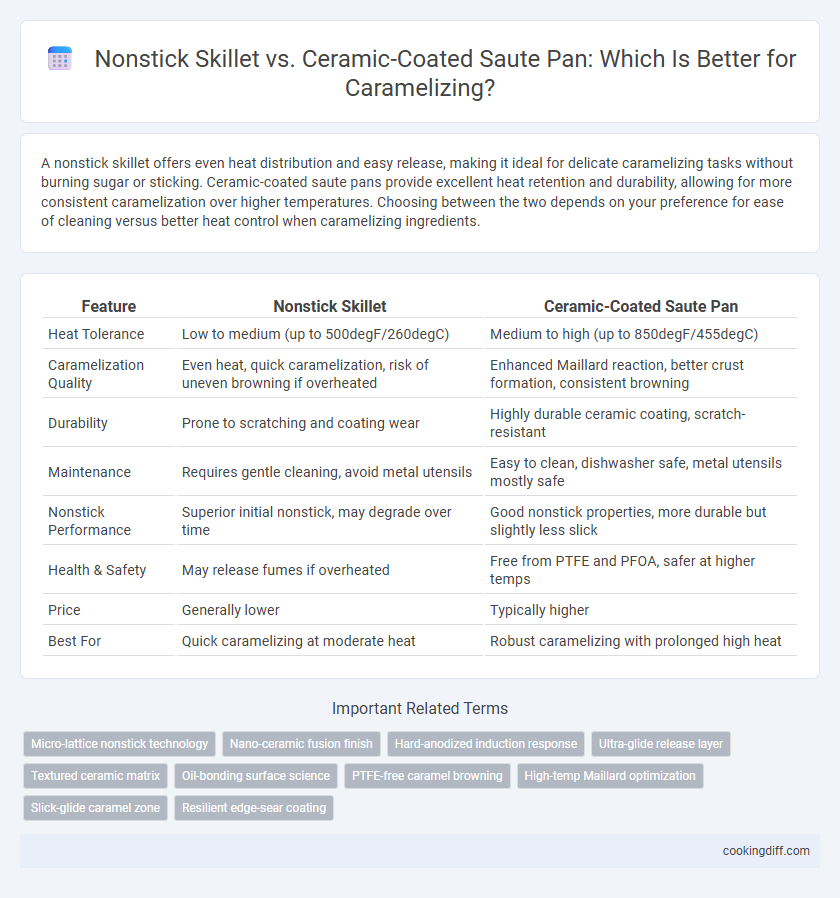

A nonstick skillet offers even heat distribution and easy release, making it ideal for delicate caramelizing tasks without burning sugar or sticking. Ceramic-coated saute pans provide excellent heat retention and durability, allowing for more consistent caramelization over higher temperatures. Choosing between the two depends on your preference for ease of cleaning versus better heat control when caramelizing ingredients.

Table of Comparison

| Feature | Nonstick Skillet | Ceramic-Coated Saute Pan |

|---|---|---|

| Heat Tolerance | Low to medium (up to 500degF/260degC) | Medium to high (up to 850degF/455degC) |

| Caramelization Quality | Even heat, quick caramelization, risk of uneven browning if overheated | Enhanced Maillard reaction, better crust formation, consistent browning |

| Durability | Prone to scratching and coating wear | Highly durable ceramic coating, scratch-resistant |

| Maintenance | Requires gentle cleaning, avoid metal utensils | Easy to clean, dishwasher safe, metal utensils mostly safe |

| Nonstick Performance | Superior initial nonstick, may degrade over time | Good nonstick properties, more durable but slightly less slick |

| Health & Safety | May release fumes if overheated | Free from PTFE and PFOA, safer at higher temps |

| Price | Generally lower | Typically higher |

| Best For | Quick caramelizing at moderate heat | Robust caramelizing with prolonged high heat |

Introduction to Caramelizing: Choosing the Right Pan

| Caramelizing involves cooking sugar slowly to develop rich flavor and color, requiring precise temperature control. A nonstick skillet offers even heat distribution and easy release, preventing sugar from sticking and burning, ideal for beginners. Ceramic-coated saute pans provide superior heat retention and chemical-free surfaces, enhancing caramelization while ensuring a natural cooking experience. |

Nonstick Skillets: Features and Benefits for Caramelizing

Nonstick skillets feature a smooth, coated surface that prevents sugar and butter from sticking during caramelizing, ensuring even browning and easy cleanup. Their superior heat distribution promotes consistent caramelization without hot spots that can burn the sugar. These pans also require less oil, making them ideal for achieving the perfect caramel texture with minimal fat.

Ceramic-Coated Sauté Pans: Advantages in Caramelization

Ceramic-coated saute pans offer superior heat retention and even distribution, which are crucial for achieving perfect caramelization without burning. Their non-reactive surface prevents sugar from sticking and reacting chemically, preserving the rich flavor and color of caramelized ingredients.

The ceramic coating also allows higher temperature tolerance compared to traditional nonstick skillets, enabling more precise control during the caramelization process. This durability and enhanced performance make ceramic-coated pans ideal for cooking delicate caramelized sauces and vegetables.

Heat Distribution: Nonstick vs Ceramic-Coated Performance

Nonstick skillets typically provide less even heat distribution compared to ceramic-coated saute pans, which excel at maintaining consistent temperatures crucial for caramelizing sugars without burning. Ceramic-coated pans' superior heat retention helps achieve uniform caramelization, enhancing flavor and texture.

- Nonstick Skillet Heat Distribution - Often features thinner bases that can create hot spots, leading to uneven caramelization.

- Ceramic-Coated Saute Pan Performance - Offers more uniform heat spread due to thicker, denser materials, reducing the risk of burnt patches.

- Impact on Caramelizing - Consistent temperature control in ceramic pans facilitates smoother, more controlled caramelization processes.

Browning and Flavor Development Comparison

Nonstick skillets offer even heat distribution that promotes consistent browning, essential for deep caramelization. Their smooth surface prevents sugars from sticking, resulting in cleaner and more controlled flavor development.

Ceramic-coated saute pans provide higher heat tolerance, enabling more intense browning and richer flavor complexity. The slightly textured surface can enhance Maillard reactions, contributing to a more robust caramelized profile.

Ease of Use and Cleanup: Which Pan is More Convenient?

Nonstick skillets offer superior ease of use and quicker cleanup when caramelizing due to their smooth surfaces that prevent sticking. Ceramic-coated saute pans require more careful temperature control but provide a durable, scratch-resistant option that cleans up well with gentle scrubbing.

- Nonstick skillet is user-friendly - Its nonstick surface minimizes food adherence, allowing effortless stirring and flipping during caramelization.

- Cleanup efficiency - Nonstick pans typically need only a soft cloth and mild detergent for easy residue removal without scrubbing.

- Ceramic-coated saute pan durability - Ceramic coating withstands higher heat and abrasion, but stubborn caramel may require soaking or careful cleaning tools.

Durability and Longevity: Nonstick vs Ceramic-Coated

Nonstick skillets often feature a PTFE coating that can wear off over time, reducing their durability when frequently used for caramelizing. Ceramic-coated saute pans offer a harder surface that resists scratching and high heat degradation, enhancing longevity during repetitive cooking processes.

Ceramic-coated pans maintain their smooth, non-reactive surface longer under intense caramelizing, preventing food from sticking and burning due to superior thermal resistance. Nonstick coatings are susceptible to chipping and can degrade faster when exposed to metal utensils or abrasive cleaning methods. Choosing a ceramic-coated saute pan improves durability and sustains optimal caramelizing performance over extended use.

Safety Considerations: Nonstick vs Ceramic Coatings

Which coating is safer for high-heat caramelizing, nonstick or ceramic? Nonstick skillets often contain PTFE, which can release harmful fumes at temperatures above 500degF, posing safety risks. Ceramic-coated saute pans withstand higher heat without toxic emissions, making them a safer option for caramelizing sugars at elevated temperatures.

Best Practices: Caramelizing Techniques for Each Pan

Nonstick skillets offer even heat distribution and require lower temperatures, making them ideal for gentle caramelization without burning sugar. Ceramic-coated saute pans can handle higher heat, allowing for deeper caramel color but need constant stirring to prevent sticking. Use medium heat for nonstick pans and medium-high heat for ceramic-coated pans to achieve perfect caramelization results.

Related Important Terms

Micro-lattice nonstick technology

Micro-lattice nonstick technology in nonstick skillets allows for superior heat distribution and prevents sugar crystals from sticking during caramelization, resulting in a smooth, even browning. Ceramic-coated saute pans, while durable and chemical-free, often lack the micro-textured surface that minimizes sticking, making nonstick skillets more efficient for precise caramelizing tasks.

Nano-ceramic fusion finish

A ceramic-coated saute pan with a nano-ceramic fusion finish provides superior heat distribution and nonstick properties ideal for caramelizing, allowing sugars to brown evenly without sticking. Unlike traditional nonstick skillets, this advanced coating enhances durability and resists high heat degradation, ensuring consistent caramelization results.

Hard-anodized induction response

Hard-anodized induction-compatible nonstick skillets offer superior heat conductivity and durability for precise caramelizing, preventing sugar from burning due to their even surface and high-temperature resistance. Ceramic-coated saute pans provide a chemical-free, easy-to-clean option with excellent heat retention but may lack the optimal induction response and long-term nonstick integrity required for consistent caramelization results.

Ultra-glide release layer

The Ultra-glide release layer on nonstick skillets offers superior caramelization by preventing sugar from sticking and burning, ensuring even browning and easy cleanup. Ceramic-coated saute pans lack this advanced coating, often resulting in uneven caramelization and more residue during cooking.

Textured ceramic matrix

A ceramic-coated saute pan with a textured ceramic matrix provides superior heat distribution and retention for even caramelization, preventing hot spots that can cause uneven browning. Unlike nonstick skillets, its durable surface withstands higher temperatures, promoting deep, rich caramel colors and enhanced flavor development.

Oil-bonding surface science

Nonstick skillets feature a fluoropolymer coating that creates a low-energy surface, preventing oil molecules from binding strongly and allowing food to release easily but potentially inhibiting the Maillard reaction essential for rich caramelization. Ceramic-coated saute pans possess a more porous surface that bonds with oil molecules, promoting even heat distribution and enhanced flavor development through better caramelization dynamics.

PTFE-free caramel browning

Ceramic-coated saute pans offer PTFE-free caramel browning with even heat distribution, reducing the risk of sticking and chemical leaching during caramelization. Nonstick skillets, typically coated with PTFE, may release harmful fumes at high temperatures, making ceramic-coated pans a safer and more durable choice for achieving perfect caramelized sugar.

High-temp Maillard optimization

Ceramic-coated saute pans offer superior heat retention and even temperature distribution, ideal for achieving the high temperatures necessary for optimal Maillard reactions during caramelizing. Nonstick skillets typically have lower heat tolerance, which can hinder the development of deep, complex flavors associated with proper caramelization.

Slick-glide caramel zone

The slick-glide caramel zone on ceramic-coated saute pans provides even heat distribution and prevents sticky buildup, enhancing the caramelization process with consistent browning. Nonstick skillets may lack the robust heat retention necessary for deep caramelization, often resulting in less flavorful, uneven caramel layers.

Nonstick skillet vs ceramic-coated saute pan for caramelizing. Infographic

cookingdiff.com

cookingdiff.com