A traditional sugar thermometer provides direct contact measurement, offering precise temperature control essential for achieving perfect caramelization without burning. Infrared thermometers measure surface temperature from a distance, allowing for quick readings but may be less accurate on reflective or uneven surfaces. Choosing the right thermometer depends on accuracy needs and convenience during the caramelizing process.

Table of Comparison

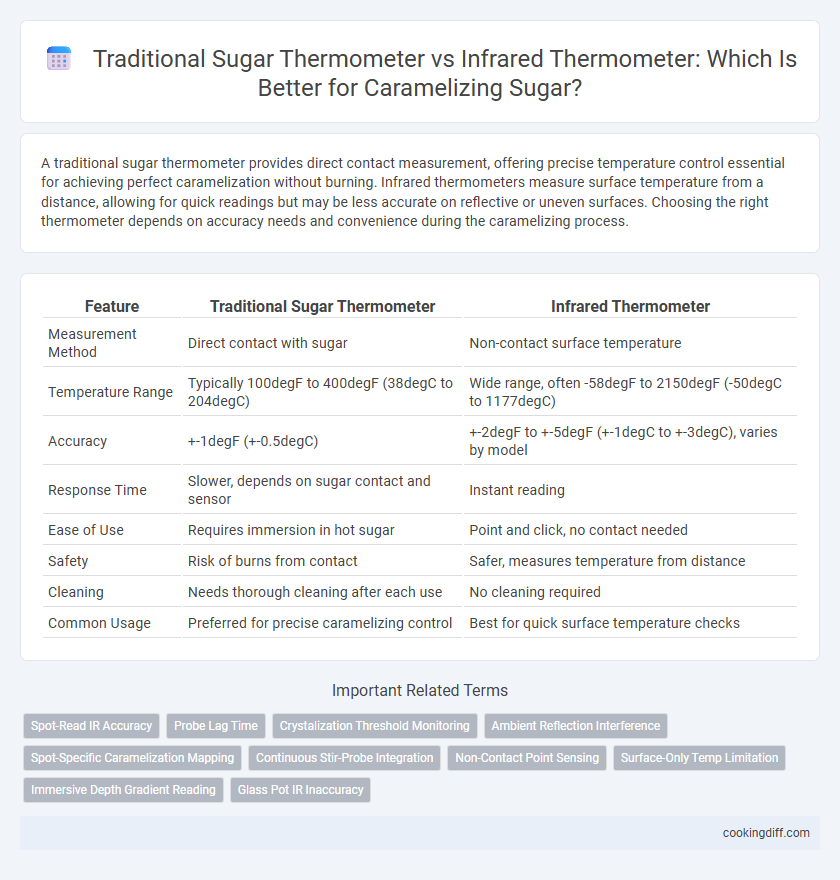

| Feature | Traditional Sugar Thermometer | Infrared Thermometer |

|---|---|---|

| Measurement Method | Direct contact with sugar | Non-contact surface temperature |

| Temperature Range | Typically 100degF to 400degF (38degC to 204degC) | Wide range, often -58degF to 2150degF (-50degC to 1177degC) |

| Accuracy | +-1degF (+-0.5degC) | +-2degF to +-5degF (+-1degC to +-3degC), varies by model |

| Response Time | Slower, depends on sugar contact and sensor | Instant reading |

| Ease of Use | Requires immersion in hot sugar | Point and click, no contact needed |

| Safety | Risk of burns from contact | Safer, measures temperature from distance |

| Cleaning | Needs thorough cleaning after each use | No cleaning required |

| Common Usage | Preferred for precise caramelizing control | Best for quick surface temperature checks |

Understanding Caramelization: Science and Technique

Which thermometer provides more accurate temperature readings for caramelizing sugar? Traditional sugar thermometers measure the actual temperature of the sugar by direct contact, ensuring precise control over the caramelization process. Infrared thermometers offer rapid, non-contact surface readings but may be less reliable due to sugar's reflective properties during caramelization.

The Role of Temperature Control in Caramelizing Sugar

| Traditional Sugar Thermometer | Provides direct contact measurement, ensuring precise temperature control essential for achieving the optimal caramelization point between 320degF and 350degF (160degC and 177degC). |

| Infrared Thermometer | Offers non-contact temperature readings with quick surface measurement but may be less accurate for liquid sugar due to reflective surfaces and inconsistent heat distribution. |

| Temperature Control Importance | Maintaining exact temperature prevents sugar from burning or crystallizing, directly impacting color, flavor, and texture in caramelized sugar products. |

Traditional Sugar Thermometers: Features and Functionality

Traditional sugar thermometers feature a long probe designed to be immersed directly in the sugar mixture, providing precise temperature readings essential for caramelizing. They typically measure temperatures ranging from 100degF to 400degF, allowing cooks to monitor the sugar's exact stage, such as soft ball, hard crack, or caramel temperature.

These thermometers rely on direct contact with the sugar, ensuring accurate heat measurement by detecting the liquid's temperature rather than surface heat. Their functionality includes clear, easy-to-read dials or digital displays, often with color-coded zones to guide caramelizing processes precisely.

Infrared Thermometers: Modern Precision in the Kitchen

Infrared thermometers provide precise, non-contact temperature readings essential for perfect caramelizing by accurately measuring the surface temperature of sugar without contamination. Unlike traditional sugar thermometers that require submersion and risk burning or uneven heating, infrared thermometers deliver instant results, enhancing control over the caramelization process. Their advanced sensor technology ensures consistent caramel quality, making them a valuable tool for both professional chefs and home cooks aiming for exact temperature monitoring.

Accuracy Showdown: Traditional vs Infrared Thermometers

Traditional sugar thermometers provide precise, direct contact readings essential for accurate caramelization between 320degF and 350degF. Infrared thermometers offer non-contact measurements but may vary due to surface reflections and emissivity differences, impacting consistent temperature readings.

- Direct Contact Precision - Traditional thermometers measure the actual sugar temperature, reducing errors caused by ambient heat and surface inconsistencies.

- Surface Temperature Variability - Infrared thermometers can register misleading temperatures if the sugar's glossy surface reflects ambient light or varies in texture.

- Calibration Reliability - Traditional devices typically maintain stable calibration for prolonged use, ensuring consistent caramelization outcomes.

Ease of Use: Hands-On vs Touchless Temperature Reading

The traditional sugar thermometer requires direct contact with the caramel for accurate temperature readings, offering hands-on control during the cooking process. Infrared thermometers provide touchless temperature measurement, allowing users to monitor caramelization without immersion, enhancing safety and convenience.

- Hands-On Measurement - Traditional thermometers must be inserted into the sugar, ensuring precise heat tracking but requiring careful handling to avoid burns.

- Touchless Reading - Infrared thermometers measure surface temperature from a distance, reducing the risk of contamination and injury during caramelization.

- Ease of Use - Infrared devices offer quicker, simpler readings that do not interrupt the cooking process, while traditional thermometers demand constant attention and repositioning.

Choosing between these thermometers depends on whether precision or convenience is the primary priority during caramelizing.

Cleaning and Maintenance: Comparing Both Tools

Traditional sugar thermometers require thorough cleaning after each use to prevent sugar residue buildup, which can affect accuracy and lifespan. Their metal probe and glass or metal casing need soaking and careful scrubbing to avoid sticky caramel remnants.

Infrared thermometers offer easier maintenance as they do not come into direct contact with the sugar, reducing the risk of residue accumulation. Cleaning typically involves wiping the sensor lens with a soft cloth, minimizing effort and downtime between uses.

Cost Analysis: Investment and Longevity

The initial investment for a traditional sugar thermometer typically ranges between $10 and $30, offering durable metal construction that can last for years with proper care. Infrared thermometers, priced from $40 to $100, provide instant temperature readings without contact but may require battery replacements and occasional calibration. Over time, the traditional thermometer's low maintenance costs contrast with the infrared device's higher upfront cost, making the former more cost-effective for consistent caramelizing tasks in home kitchens.

Best Practices for Reliable Caramelization

Using a traditional sugar thermometer provides direct contact measurement, ensuring accurate and consistent temperature readings during caramelization. Infrared thermometers offer non-contact readings but may be less reliable due to surface reflections and uneven heating.

- Calibrate regularly - Both thermometers require frequent calibration to maintain precision in temperature monitoring.

- Use proper positioning - For infrared thermometers, aim steadily at the sugar surface without obstructions to avoid inaccurate readings.

- Combine methods - Employing a traditional thermometer for continuous contact measurement paired with infrared checks can enhance reliability in caramelizing.

Related Important Terms

Spot-Read IR Accuracy

Traditional sugar thermometers provide continuous immersion readings crucial for precise temperature control during caramelizing, but their accuracy can be compromised by hot spots and stirring inconsistencies. Infrared thermometers offer spot-read accuracy and immediate surface temperature measurements, enabling faster adjustments and reducing the risk of burning caramel.

Probe Lag Time

Traditional sugar thermometers with probe lag time often result in slower temperature readings during caramelizing, causing inaccuracies in achieving the perfect caramel stage. Infrared thermometers provide near-instantaneous surface temperature readings, minimizing lag and enhancing precision for optimal caramelization control.

Crystalization Threshold Monitoring

Traditional sugar thermometers provide precise temperature readings by direct contact, enabling accurate monitoring of the sugar's crystallization threshold during caramelizing. Infrared thermometers offer non-contact surface temperature measurements but may struggle to detect internal sugar crystal formation, making them less reliable for preventing unwanted crystallization.

Ambient Reflection Interference

Traditional sugar thermometers provide direct contact temperature readings crucial for precise caramelization but are susceptible to ambient reflection interference that can cause inaccurate surface temperature readings. Infrared thermometers minimize ambient reflection interference by measuring surface temperature from a distance, offering faster, non-contact readings ideal for monitoring caramelization stages without risking contamination.

Spot-Specific Caramelization Mapping

Traditional sugar thermometers provide precise temperature readings by direct contact, essential for accurate caramelization control, but lack the ability to map temperature variations across the surface. Infrared thermometers offer spot-specific caramelization mapping, enabling targeted heat monitoring and ensuring uniform browning by detecting surface temperature differences without contact.

Continuous Stir-Probe Integration

Traditional sugar thermometers provide continuous temperature readings through direct probe contact, enabling precise monitoring during caramelizing for consistent crystallization control. Infrared thermometers, lacking probe integration, offer non-contact surface temperature measurements but may result in less accurate caramelization due to uneven heat distribution and absence of real-time stirring feedback.

Non-Contact Point Sensing

Infrared thermometers provide precise non-contact point sensing for caramelizing, allowing accurate temperature readings without disturbing the sugar's surface or risking contamination. Traditional sugar thermometers require immersion directly in the caramel, which can affect the texture and cooling rate, while infrared devices measure surface temperature instantly, enhancing control over caramelization stages.

Surface-Only Temp Limitation

Traditional sugar thermometers measure temperature by direct contact, providing precise readings within the caramel but often failing to accurately reflect the surface temperature where caramelization occurs. Infrared thermometers excel at detecting surface-only temperatures quickly and without contact, making them superior for monitoring the exact caramelizing point and preventing burning.

Immersive Depth Gradient Reading

Traditional sugar thermometers provide immersive depth gradient reading by being submerged directly into the caramelizing sugar, ensuring precise temperature measurement throughout the liquid's temperature layers. Infrared thermometers, while non-contact and quick, offer surface-level readings that lack the immersive gradient depth, potentially missing temperature variations critical for perfect caramelization.

Traditional Sugar Thermometer vs Infrared Thermometer for caramelizing. Infographic

cookingdiff.com

cookingdiff.com