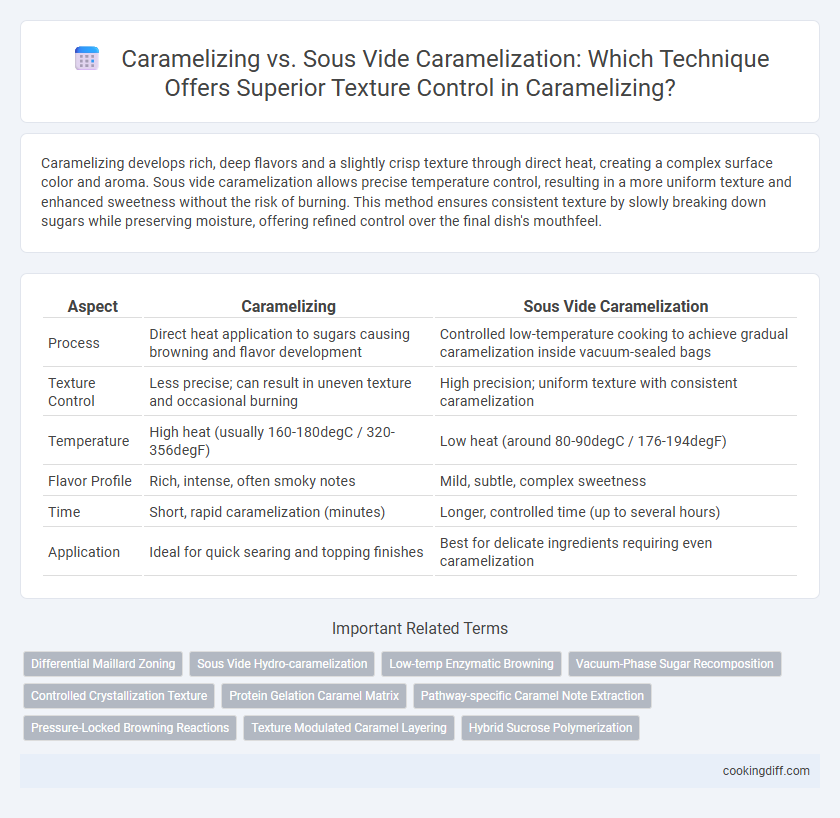

Caramelizing develops rich, deep flavors and a slightly crisp texture through direct heat, creating a complex surface color and aroma. Sous vide caramelization allows precise temperature control, resulting in a more uniform texture and enhanced sweetness without the risk of burning. This method ensures consistent texture by slowly breaking down sugars while preserving moisture, offering refined control over the final dish's mouthfeel.

Table of Comparison

| Aspect | Caramelizing | Sous Vide Caramelization |

|---|---|---|

| Process | Direct heat application to sugars causing browning and flavor development | Controlled low-temperature cooking to achieve gradual caramelization inside vacuum-sealed bags |

| Texture Control | Less precise; can result in uneven texture and occasional burning | High precision; uniform texture with consistent caramelization |

| Temperature | High heat (usually 160-180degC / 320-356degF) | Low heat (around 80-90degC / 176-194degF) |

| Flavor Profile | Rich, intense, often smoky notes | Mild, subtle, complex sweetness |

| Time | Short, rapid caramelization (minutes) | Longer, controlled time (up to several hours) |

| Application | Ideal for quick searing and topping finishes | Best for delicate ingredients requiring even caramelization |

Understanding Caramelization in Cooking

Caramelizing involves cooking sugars at high heat to develop rich flavors and a crisp texture, while sous vide caramelization uses controlled low temperatures for precise texture control and enhanced flavor infusion. Understanding the science behind caramelization helps chefs optimize the balance between sweetness, texture, and aroma in various dishes.

- Caramelizing - transforms sugars by heating them above 320degF, creating complex flavors and a crunchy exterior.

- Sous Vide Caramelization - utilizes exact temperature control below traditional caramelizing points for uniform texture and depth of flavor.

- Texture Control - combining both methods allows chefs to tailor caramelized foods' crispness and tenderness effectively.

Mastering caramelization techniques enhances culinary creativity by enabling precise flavor and texture development.

What Is Sous Vide Caramelization?

Sous vide caramelization involves cooking food sealed in a vacuum bag at precise, low temperatures to achieve controlled Maillard reactions without burning. This method enhances flavor development and texture consistency by maintaining moisture and preventing overcooking.

- Precise Temperature Control - Sous vide allows exact regulation of heat, ensuring even caramelization without charring.

- Enhanced Texture - The vacuum-sealed environment preserves moisture, resulting in tender, uniformly caramelized food.

- Flavor Concentration - Slow cooking intensifies natural sugars, producing deeper and more complex caramel flavors.

Traditional Caramelizing Techniques Explained

Traditional caramelizing involves cooking sugar or foods with natural sugars over direct heat to develop a rich, brown crust and complex flavor profile. This method relies on precise temperature control and timing to achieve the Maillard reaction and perfect caramel color.

Compared to sous vide caramelization, traditional caramelizing offers less uniform texture control but enhances crispness and depth through direct caramel contact. Mastery of techniques like stovetop caramelizing or oven roasting is essential for achieving desired textures and flavors in classic dishes.

Key Differences: Caramelizing vs Sous Vide Caramelization

Caramelizing transforms sugars through direct heat, creating crisp textures and deep brown flavors, while sous vide caramelization uses controlled low temperatures to develop sweetness without altering food texture significantly. This method enhances sweetness uniformly, preserving the moisture and tenderness of the food.

- Heat Application - Traditional caramelizing uses high heat directly on food surfaces, whereas sous vide caramelization involves prolonged exposure to moderate temperatures in a sealed environment.

- Texture Control - Caramelizing results in a crunchy or crispy exterior, while sous vide caramelization maintains a soft, uniform texture throughout.

- Flavor Development - Direct caramelizing produces intense, complex brown flavors; sous vide caramelization yields sweeter, subtler flavor profiles due to gradual sugar transformation.

Texture Control: Traditional Caramelizing Outcomes

| Traditional caramelizing involves direct high heat application, resulting in a crisp, slightly crunchy texture due to Maillard reaction and sugar polymerization. The rapid temperature increase promotes uneven caramel development, causing variable browning and texture inconsistencies on the food's surface. This technique offers less precise control over texture, often producing a firmer exterior while risking interior moisture loss and toughness. |

Texture Results with Sous Vide Caramelization

Sous vide caramelization offers precise temperature control, resulting in a consistently smooth and tender texture that is difficult to achieve with traditional caramelizing methods. This technique prevents overcooking and uneven browning, enhancing the overall mouthfeel of the caramelized product.

Compared to conventional caramelizing, sous vide caramelization allows for extended cooking times at lower temperatures, which breaks down sugars evenly and maintains moisture content. The controlled environment reduces the risk of burnt or grainy textures, creating a silky finish that enhances both flavor and visual appeal. Chefs can fine-tune texture profiles to suit specific dishes, making sous vide caramelization ideal for delicate or complex recipes.

Comparing Flavor Profiles: Traditional vs Sous Vide

How do flavor profiles differ between traditional caramelizing and sous vide caramelization methods? Traditional caramelizing develops a deep, rich, and slightly bitter flavor due to direct high heat exposure, while sous vide caramelization produces a more delicate, evenly sweet flavor by gently heating the sugars at a controlled temperature. This precision in sous vide enhances subtle caramel notes and maintains a consistent texture without the risk of burning.

Benefits and Limitations of Each Method

Caramelizing involves applying direct heat to sugar, resulting in a rich, deep flavor and a crisp texture ideal for toppings and sauces. This method offers quick browning but risks uneven caramelization and potential burning if not closely monitored.

Sous vide caramelization delivers precise temperature control, allowing for consistent texture and uniform flavor development over extended cooking times. However, it lacks the classic crispness of traditional caramelizing and requires specialized equipment for optimal results.

Choosing the Right Method for Desired Texture

Caramelizing involves high-heat cooking that creates a crisp, rich exterior through Maillard reactions, ideal for achieving a crunchy texture. Sous vide caramelization uses precise temperature control to gently develop sweetness and tenderness without overcooking, resulting in a smooth, silky texture. Choosing between these methods depends on whether a firm crust or tender interior is prioritized for the dish's final texture.

Related Important Terms

Differential Maillard Zoning

Caramelizing develops a range of Maillard reaction zones creating crispy, uneven textures on food surfaces, while sous vide caramelization enables precise control over these zones by regulating temperature and time for uniform browning and tender interiors. Differential Maillard zoning in sous vide achieves consistent texture refinement by avoiding overbrowning, unlike traditional caramelizing which risks burnt spots and textural inconsistencies.

Sous Vide Hydro-caramelization

Sous vide hydro-caramelization offers precise temperature control, enabling uniform Maillard reactions that enhance sweetness and complex flavor profiles without over-browning. This method maintains optimal texture by gently softening ingredients while developing rich caramel notes, outperforming traditional caramelizing techniques that risk uneven cooking and textural inconsistencies.

Low-temp Enzymatic Browning

Caramelizing involves high heat to create a deep, rich flavor through sugar breakdown, while sous vide caramelization employs controlled low temperatures that leverage enzymatic browning for precise texture control and enhanced sweetness. Low-temp enzymatic browning in sous vide preserves moisture and produces a tender, evenly caramelized surface without the bitterness often found in direct high-heat caramelization.

Vacuum-Phase Sugar Recomposition

Caramelizing through traditional methods relies on direct heat to initiate the Maillard reaction and sugar browning, often resulting in uneven texture and flavor distribution. Vacuum-phase sugar recomposition in sous vide caramelization offers precise control over temperature and pressure, enabling uniform sugar crystallization and enhanced texture consistency by preventing caramel degradation and promoting deeper flavor infusion.

Controlled Crystallization Texture

Caramelizing relies on direct heat to induce Maillard reactions and sugar browning, creating a rich flavor but often resulting in uneven texture due to uncontrolled crystallization. Sous vide caramelization enables precise temperature control, allowing for consistent sugar crystallization and a smooth, uniform texture by preventing premature burning and ensuring even caramel development.

Protein Gelation Caramel Matrix

Caramelizing develops a complex caramel matrix through high heat, promoting protein gelation that enhances texture firmness and flavor depth, ideal for crisp outer layers. Sous vide caramelization controls temperature precisely to create a uniform caramel matrix with consistent protein gelation, resulting in tender textures and balanced caramel notes.

Pathway-specific Caramel Note Extraction

Caramelizing relies on high heat to induce Maillard reactions and sugar pyrolysis, creating rich, complex caramel notes through surface browning, while sous vide caramelization enables precise temperature control to extract specific caramel compounds without overcooking, preserving texture and depth of flavor. Pathway-specific caramel note extraction via sous vide allows fine-tuning of molecular transformations, optimizing sweetness and mouthfeel by targeting precise stages of sugar breakdown and amino acid interaction.

Pressure-Locked Browning Reactions

Caramelizing relies on direct heat to trigger Maillard and caramelization reactions, creating a rich, complex texture through surface browning and sugar degradation. Sous vide caramelization uses precise temperature control and pressure-locking to enhance browning reactions while maintaining moisture, resulting in more uniform texture and intensified flavor without overcooking.

Texture Modulated Caramel Layering

Caramelizing creates a rich, crisp caramel layer through high heat, producing a textured contrast ideal for desserts requiring a firm bite. Sous vide caramelization, by controlling temperature precisely, allows for a modulated caramel layer with uniform softness and nuanced textures, enhancing mouthfeel without compromising moisture retention.

Caramelizing vs Sous Vide Caramelization for texture control. Infographic

cookingdiff.com

cookingdiff.com